P 3.2

SECTION III

Maintenance

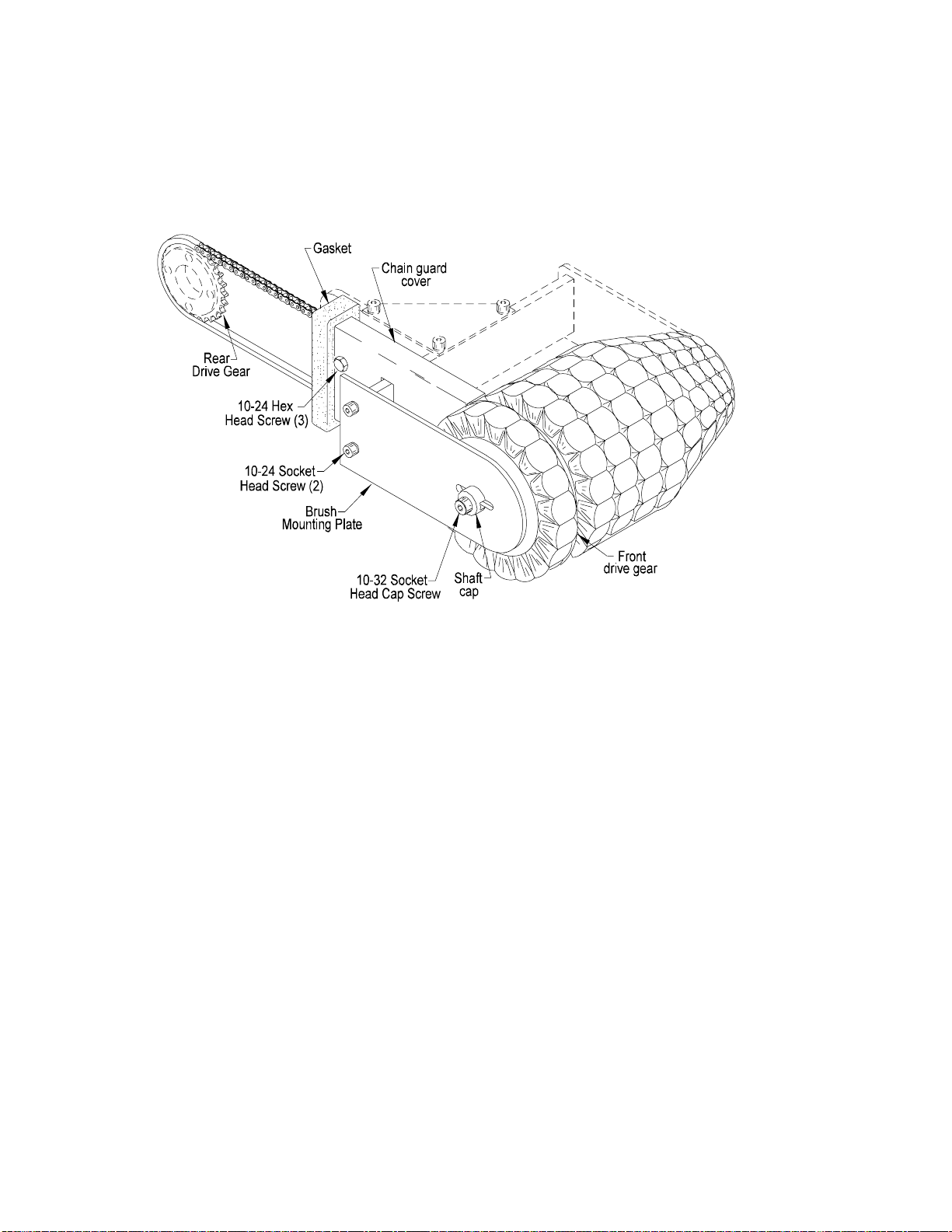

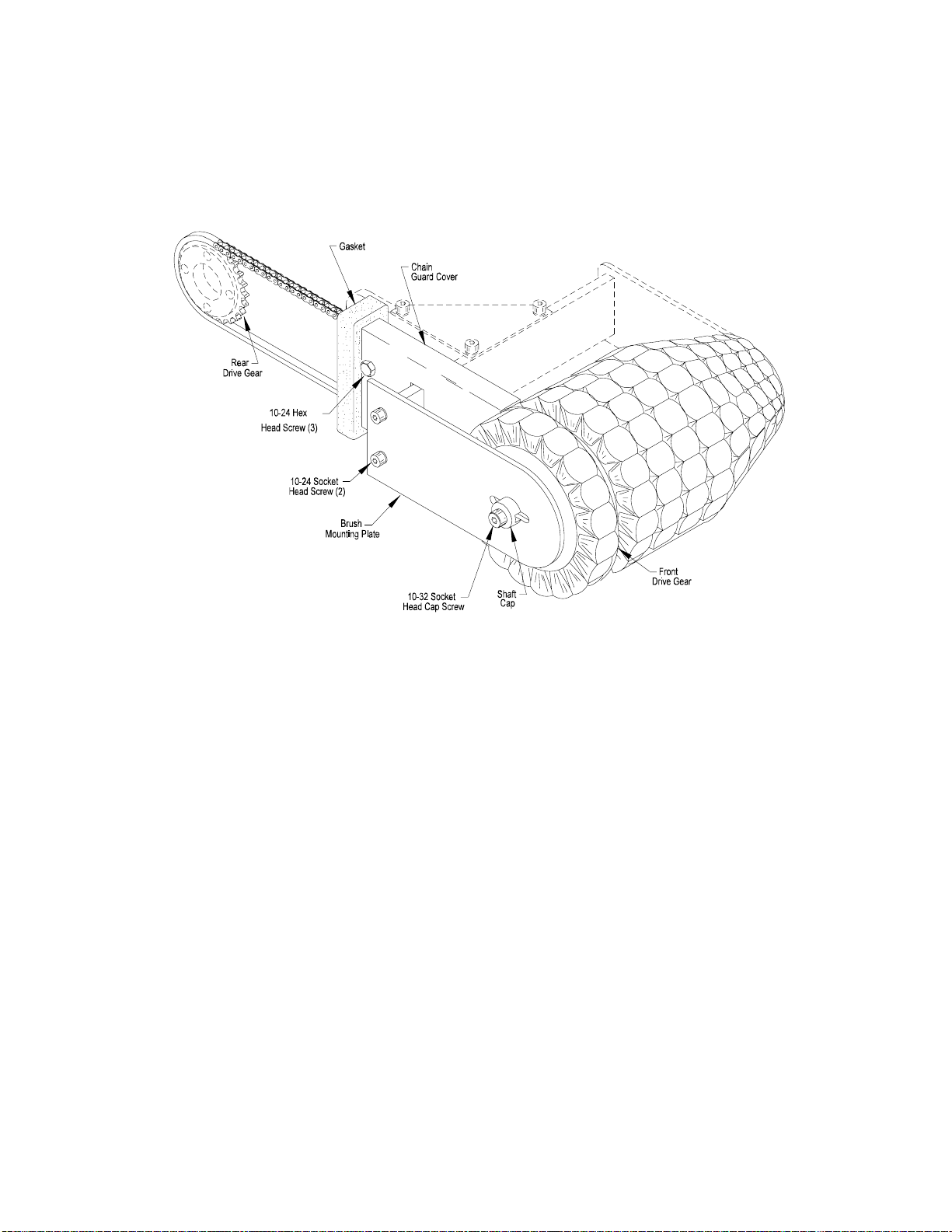

C. CHAIN REPLACEMENT PROCEDURE:

Figure 3.2

The drive chains, are preassembled at the chain

factory, and have no Master Links. The chain is

also lubricated at the factory. (stainless steel drive

chain excluded). The chains can be replaced with

out breaking the chain apart.

1. Disconnect power to the bag tensioner.

2. Remove the main gear cover.

3. Remove the two 10-32 socket head screws

connecting the shaft cap to the ends of the

brush shaft. Remove the two 10-24 socket

head screws at the rear of the brush mounting

plate and remove the plate from the tensioner.

4. Remove the three 10-24 hex head screws,

which fasten the chain guard cover to the

chain guard mounting block. Remove the

cover from the tensioner.

5. Turn the brush assembly by hand and work the

chain off the drive gear at the rear of the

tensioner.

6. Remove the chain from the tensioner.

7. Install the new chain around the brush

assembly sprocket. Work the chain through the

gasket and then around the second sprocket.

8. Replace the chain guide cover, the brush

mounting plate and the main gear cover.

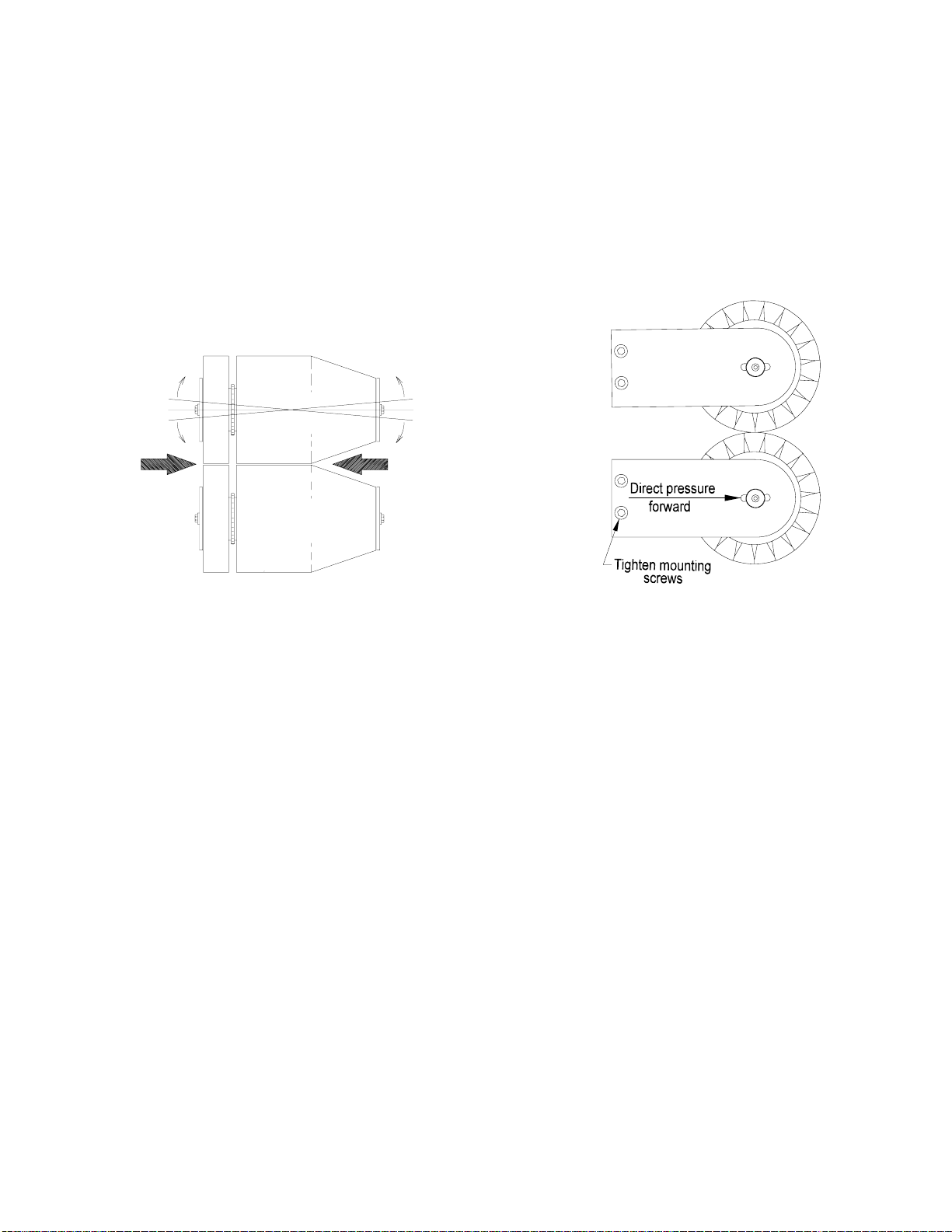

9. Refer to part A. number 2 to adjust the tension

of the new chain before operating the tensioner

under power.

D. MOTOR RESET:

Thermal overload protection is built into the bag ten-

sioner motor. Should the thermal overload trip, reset the

motor as follows:

1. Allow the motor to cool. Remove power from

the bag tensioner to reset the thermal overload.

Apply power to the bag tensioner to restart the

motor.

Figure 3.2

J8S 06 04