Electric Steps #888 Page 8

Troubleshooting and Testing Procedures, Cont

TESTING THE STEP

1. Inspect the step for visible damage that might restrict step operation

2. Obtain a 4-way pigtail connector (part #909306000) from Kwikee

3. Diconnect 4-way connector on underside of step and connect the step-half of the

connector to the four-way connector pigtail. See Figures 10, 11, and 12 on

Page 9

4. Set a fully charged 12V DC automotive battery beside the step.

NOTE: Do not allow the battery terminals to come in contact

with the step.

Complete a ground for the step tests by connecting a 10 gauge wire from the

negative (-) battery post to the green ground wire of the control unit

5. To supply power, attach the red wire from the pigtail to the battery’s positive (+)

post. The step will extend

6. With the power and ground connections complete, all functions of the control unit

can be checked at the four wires of the pigtail. The brown wire is the door

switch, the white wire is the step lockout switch, and the yellow wire is the

ignition override

7. To retract the step, touch the brown wire to the negative (-) terminal

8. To extend the step, remove the brown wire from the negative (-) terminal

9. To test the ignition override feature, extend the step as in Step 8. With the step

extended, connect the white wire to the positive (+) terminal and attach the

brown wire to the negative (-) terminal. Next, touch the yellow wire to the

battery’s positive (+) terminal. The step should retract. Remove the brown wire

and the step should extend

10.If any of the step functions do not work, the source of the malfunction is either in

the control unit and/or the motor. Proceed to the “Testing the Motor” section on

Page 10.

If all of the step functions do work, the malfunction is either in the door switch, step

lockout switch, or the vehicle wiring. Proceed to “Testing the 4-way Connector”

section on Page 10.

To test the “Auto Extend” feature, touch the brown wire to the negative (-) terminal to

retract the step. While holding the brown wire to the negative (-) terminal, remove

the yellow from the positive (+) terminal. Touch the white wire to the positive (+)

terminal. The step will stay retracted.

Now, remove the brown wire and the step should extend

Next touch the brown wire to the negative (-) terminal. The step should stay

extended.

IMPORTANT INSTALLER NOTES:

Be sure that all ground

connections are securely

fastened with good

metal-to-metal contact. A

good ground is required for

proper step operation

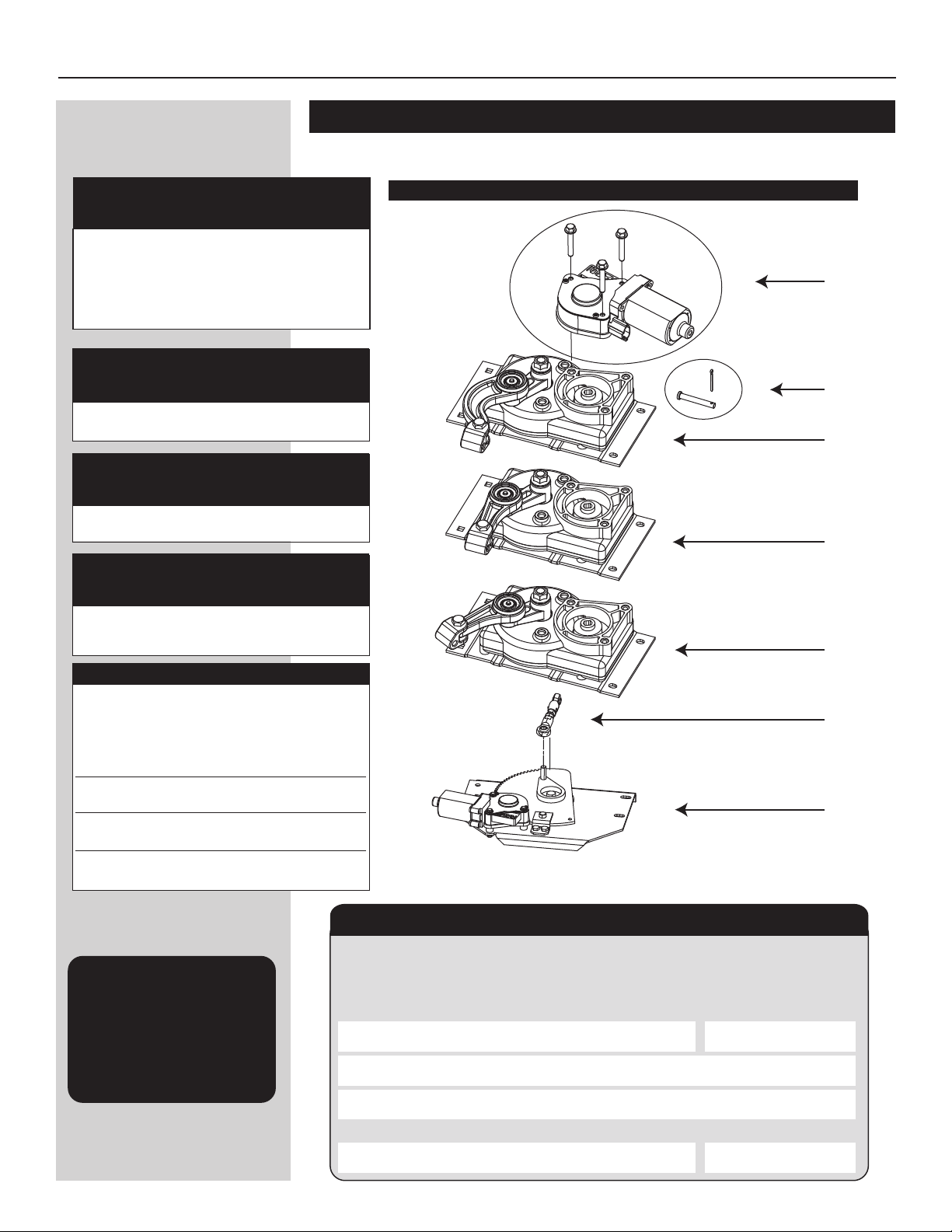

VAN STEPS

If the van step is equipped with a splash cover, remove the cover to access motor

assembly and control unit. If step is locked in retracted (up) position and the plastic

cover can not be removed, disassemble the step tread to access the plastic cover

To disassemble the tread, remove the (8) 1/4-20 x 1” long hex head bolts in tread

side rails (connects tread and sliding blocks to side rail). This allows the tread to

drop out of the way and the plastic cover to be accessible

Reassemble the tread after removing the cover. Reinstall the cover after testing

procedures and any necessary repairs are complete. Fully extend the step to

reinstall the cover. Be sure that the four-way connector exits the notch in the plastic

cover when reassembling

WARNING

!

12 volt automotive batteries

contain sulfuric acid which

can cause severe burns.

Avoid contact with the skin,

eyes, and clothing. 12 volt

automotive batteries produce

hydrogen gas which is explo-

sive; keep cigarettes, open

flames, and sparks away from

the battery at all times

WARNING

!

Keep fingers, arms, and legs

clear of step mechanism while

performing these test. Failure

to do so may result in

personal injury

CAUTION

!

Do not allow the battery

terminals to come in

contact with the step.