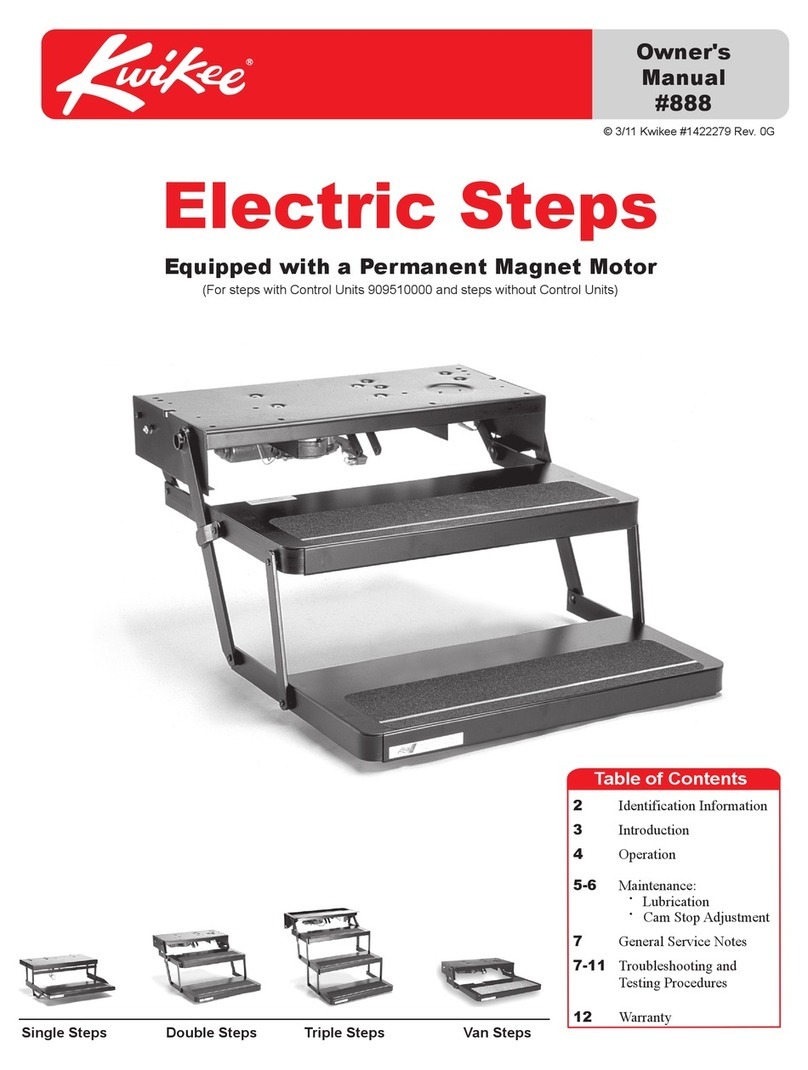

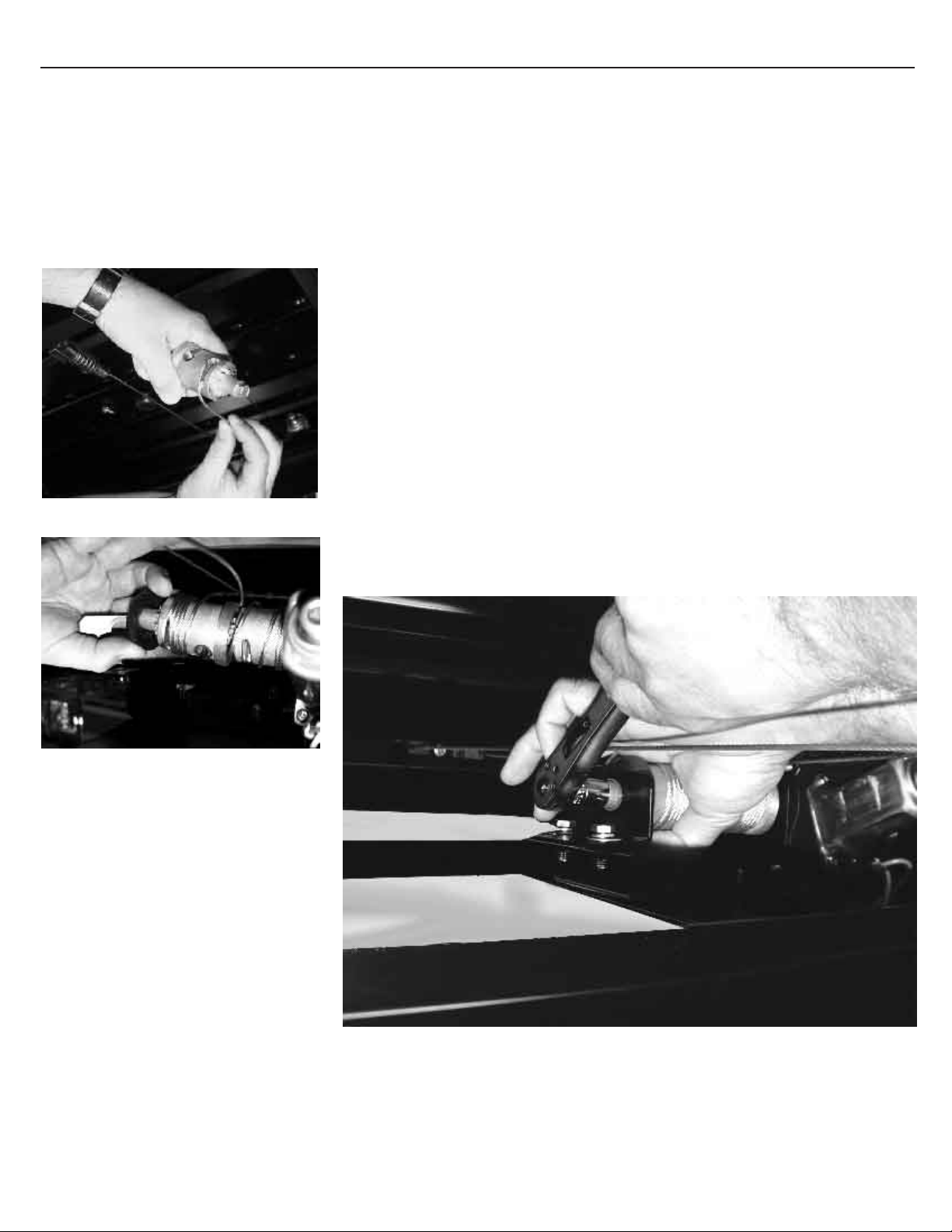

Figure 4A

Figure 4B

Figure 5

90615 Series Step Well Cover Operating Instructions Page 2

Cable Rewind Procedure

In the event that the emergency cable

release is activated, the cable system will

need to be reconnected. The following

procedure should be followed to

reconnect the cable system.

1. Manually extend the floor slide to

approximately ¾ of full travel and

have someone hold it in this position

or lock it in this position using a cut

block of wood or other part that is of

suitable length and will not scratch

the floor slide.

2. Locate the spring assembly that was

released from the cable release latch

(Figure 2).

3. Pull it out toward the front of the unit

and set it aside.

4. Remove the two ¼"-20-hex bolts, flat

washers, and lock washers that hold

the cable drum in place and set them

where they will be easily accessible

for later use (Figure 3).

5. Remove the black plastic end cap

and outer drum assembly and set

aside for later use.

6. Remove the inner drum (closest to

the motor) and unwind the cable that

is attached to it. If the cable is no

longer attached to the drum, insert

the crimped cable end into the slot

located next to the female end of the

drum. Begin winding the cable in a

clockwise direction as viewed from

the male end of the drum. Wind the

cable on the drum so that it is shorter

than what is needed to slip the motor

side over the motor gear. Make sure

not to cross the cable and make even

tight wraps around the drum (Figure

4A).

Make sure that the motor side drum

cable (short cable) is connected to

the motor side spring assembly and

to the front of the slider (Figure 4B).

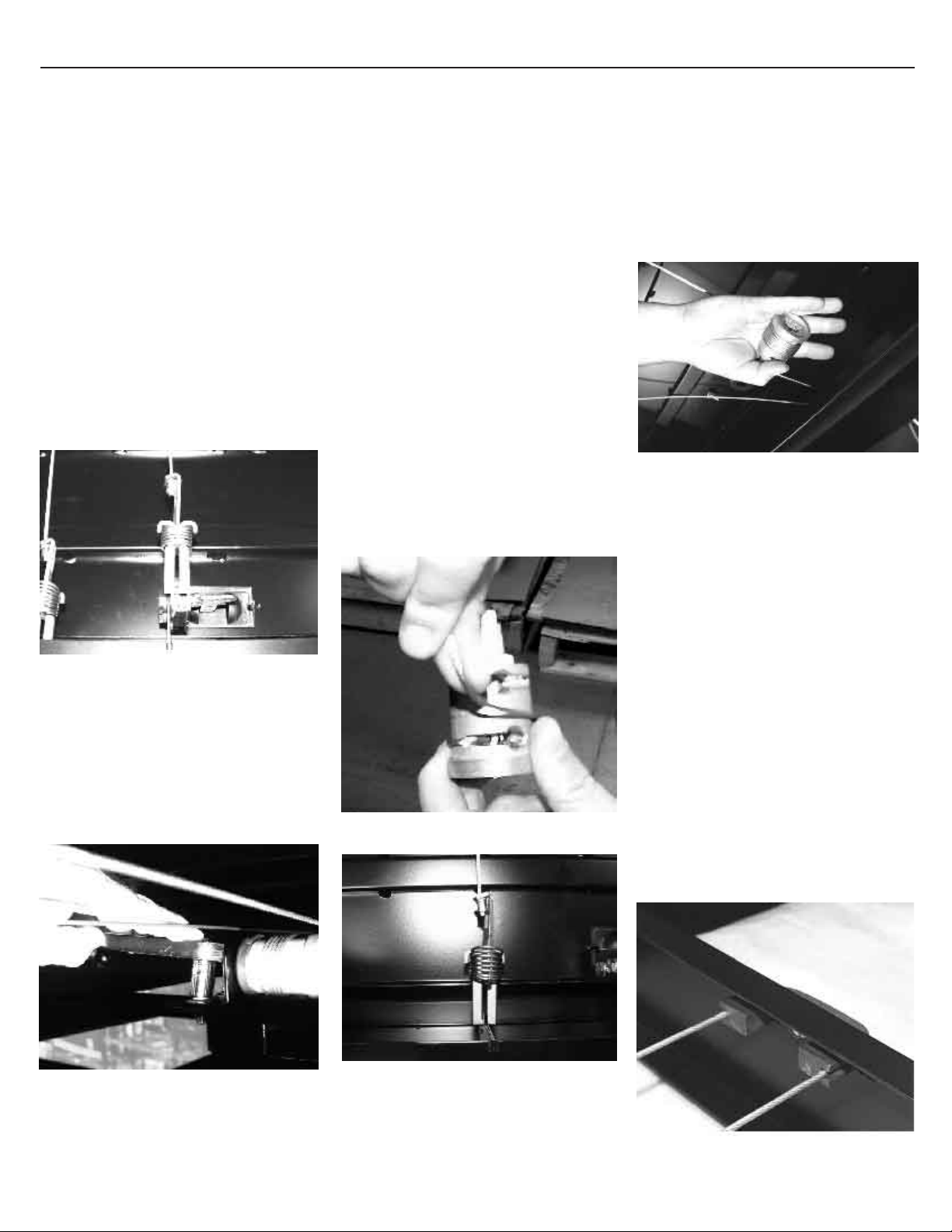

7. Grasp the drum with the cable

between your fingers and push your

hand toward the motor allowing the

drum to unwind in your hand. Make

sure to keep the cable tight. Unwind

only enough cable to align the drum

with motor gear teeth and slide the

drum over the motor gear teeth fully

(Figure 5).

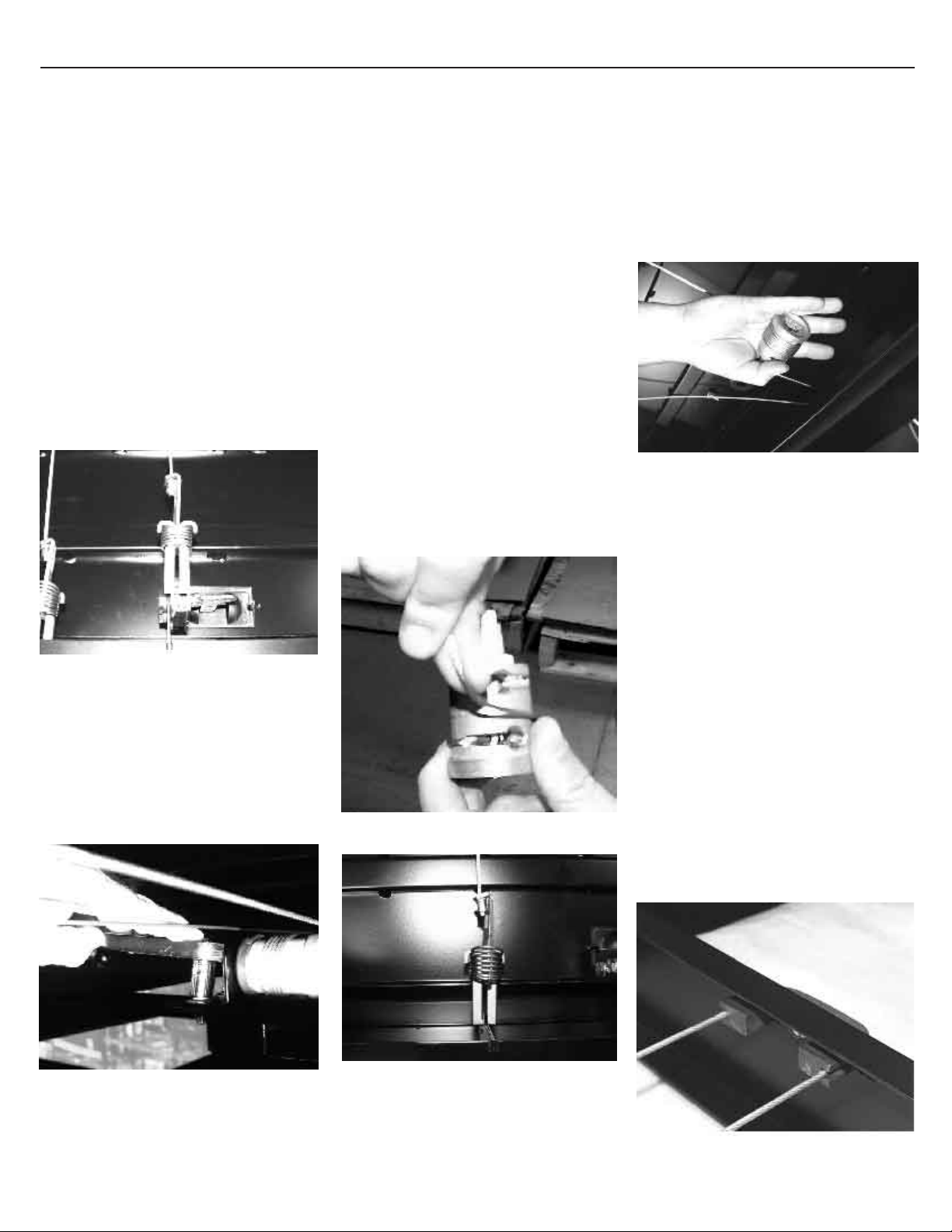

8. Connect the outer drum spring

assembly to the latch and ensure that

it is locked down and the latch is fully

closed. To accomplish this it will

require compressing the spring

slightly while closing the latch, as

shown in Figure 2.

The cable should be routed from the

spring around the plastic U-Block in

the back of the slide and up past the

motor assembly (Figure 6A). Grasp

the remaining drum and check to

ensure that the cable is inserted into

the slot on the male end of the cable

drum and begin winding the drum in a

counter clockwise direction. As you

run out of cable begin rolling the drum

in towards the drum connected to the

motor taking up the cable and winding

it on the drum as you go.

Figure 2 (Attached spring system)

Figure 3

Figure 6A