SERVICE PRECAUTIONS

nMake sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when

reassembling.

nWhen tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

nUse genuine parts and lubricants.

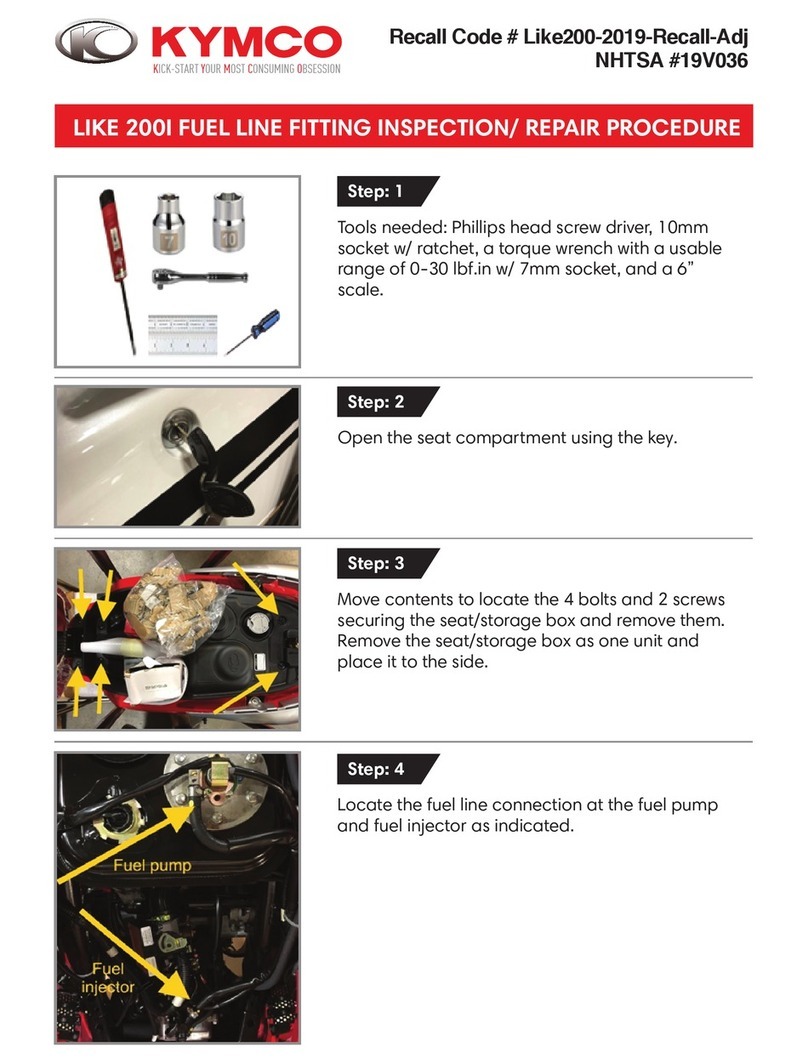

nWhen servicing the motorcycle, be sure to

use special tools for removal and

installation.

nAfter disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

nApply or add designated greases and

lubricants to the specified lubrication

points.

nAfter reassembly, check all parts for

proper tightening and operation.

nWhen two persons work together, pay

attention to the mutual working safety.

nDisconnect the battery negative (-) terminal

before operation.

nWhen using a spanner or other tools, make

sure not to damage the motorcycle surface.

nAfter operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

nWhen connecting the battery, the positive

(+) terminal must be connected first.

nAfter connection, apply grease to the

battery terminals.

nTerminal caps shall be installed securely.

nIf the fuse is burned out, find the cause and

repair it. Replace it with a new one

according to the specified capacity.

nAfter operation, terminal caps shall be

installed securely.

nWhen taking out the connector, the lock on

the connector shall be released before

operation.

nHold the connector body when connecting

or disconnecting it.

nDo not pull the connector wire.

nCheck if any connector terminal is bending,

protruding or loose.

nThe connector shall be inserted

completely.

nIf the double connector has a lock, lock

it at the correct position.

nCheck if there is any loose wire.

nBefore connecting a terminal, check for

damaged terminal cover or loose negative

terminal.

nCheck the double connector cover for

proper coverage and installation.

nInsert the terminal completely.

nCheck the terminal cover for proper

coverage.

nDo not make the terminal cover opening

face up.

nSecure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the

insulated surfaces contact the wire

harnesses.

nAfter clamping, check each wire to make

sure it is secure.

nDo not squeeze wires against the weld or

its clamp.

nAfter clamping, check each harness to make

sure that it is not interfering with any

moving or sliding parts.

nWhen fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

nRoute wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

nRoute wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.