KYMCO DINK 200 User manual

Other KYMCO Scooter manuals

KYMCO

KYMCO People User manual

KYMCO

KYMCO Mini S ForU User manual

KYMCO

KYMCO PEOPLE S 125 User manual

KYMCO

KYMCO People GT 300i User manual

KYMCO

KYMCO MYROAD 700i User manual

KYMCO

KYMCO LIKE 150i User manual

KYMCO

KYMCO Aglity 50 User manual

KYMCO

KYMCO 125 AGILITY MMC User manual

KYMCO

KYMCO Agility User manual

KYMCO

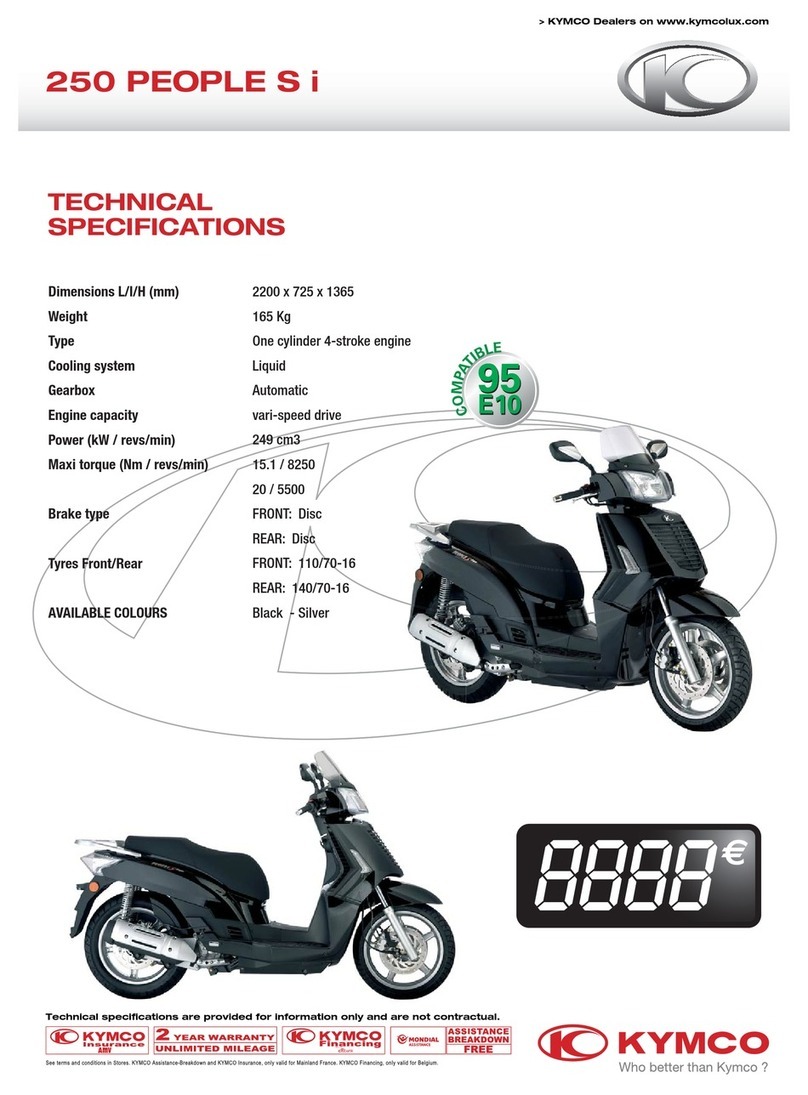

KYMCO People S 250 User manual

KYMCO

KYMCO 125 AGILITY CITY - User manual

KYMCO

KYMCO 50 DINK 4T User manual

KYMCO

KYMCO YUP 250 User manual

KYMCO

KYMCO 125 SUPER 8 User manual

KYMCO

KYMCO Bet&Win Release note

KYMCO

KYMCO FILLY LX 50 User manual

KYMCO

KYMCO Compagno 50i User manual

KYMCO

KYMCO 50 AGILITY RS 4T User manual

KYMCO

KYMCO 125 AGILITY CITY - Release note

KYMCO

KYMCO 50 AGILITY RS NAKED 2T User manual