1-1-1

2A3/4

CONTENTS

I THEORY AND CONSTRUCTION SECTION

1-1 Specifications

1-1-1 Specifications ................................................................................ 1-1-1

1-2 Handling Precautions

1-2-1 Drum ............................................................................................. 1-2-1

1-2-2 Developer and toner...................................................................... 1-2-1

1-3 Mechanical Construction

1-3-1 Parts names and their functions.................................................... 1-3-1

1-3-2 Machine cross section................................................................... 1-3-4

1-3-3 Drive system ................................................................................. 1-3-5

1-3-4 Mechanical construction................................................................ 1-3-8

II ELECTRICAL SECTION

2-1 Electrical Parts Layout

2-1-1 Electrical parts layout .................................................................... 2-1-1

2-2 Detection of Paper Misfeed

2-2-1 Paper misfeed detection ............................................................... 2-2-1

2-2-2 Paper misfeed detection conditions .............................................. 2-2-2

2-2-3 Original misfeed detection........................................................... 2-2-14

2-2-4 Original misfeed detection conditions ......................................... 2-2-15

2-3 Operation of the PCBs

2-3-1 Power source PCB ........................................................................ 2-3-1

2-3-2 Engine PCB................................................................................... 2-3-3

2-3-3 Main PCB ...................................................................................... 2-3-4

2-3-4 Memory copy PCB ........................................................................ 2-3-6

2-3-5 Scanner motor PCB ...................................................................... 2-3-8

2-3-6 CCD PCB ...................................................................................... 2-3-9

2-3-7 DF driver PCB ............................................................................. 2-3-11

2-3-8 Operation unit main PCB,operation unit right PCB,and

operation unit left PCB ................................................................ 2-3-12

2-3-9 Deck main PCB (42 ppm: optional/52 ppm: standard) ................ 2-3-16

III SET UP AND ADJUSTMENT SECTION

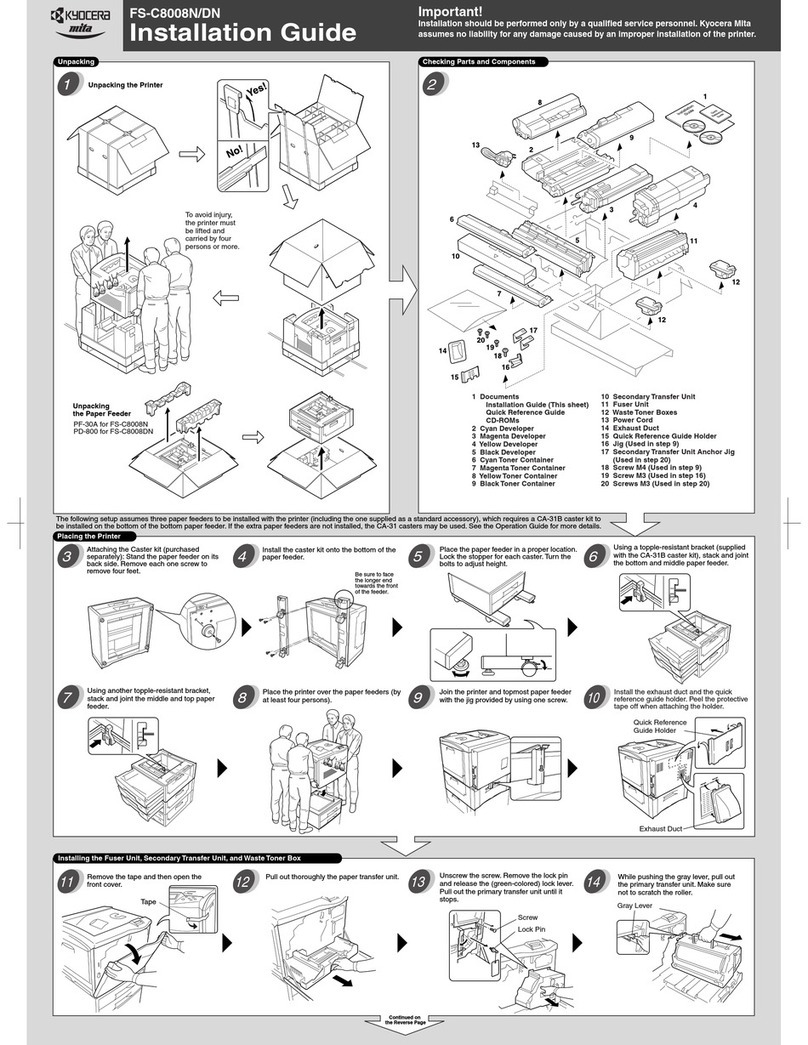

3-1 Installation

3-1-1 Unpacking and installation ............................................................ 3-1-1

3-1-2 Setting initial copy modes ........................................................... 3-1-29

3-1-3 Installing the memory copy kit

(42 ppm: optional/52 ppm: standard) .......................................... 3-1-30

3-1-4 Installing the image memory SIMM (option)................................ 3-1-33

3-1-5 Installing the optical heater (service part) ................................... 3-1-35

3-1-6 Installing the drawer heater (service part) ................................... 3-1-38

3-1-7 Installing the key counter (option) ............................................... 3-1-41

3-1-8 Installing the dehumidfier heaters (service part) ......................... 3-1-44

3-1-9 Installing the MMD host monitorig system device

(optional for 120 V specifications only) ....................................... 3-1-47