1.Safe Testing .................................................................................. 1

2.Features ........................................................................................ 3

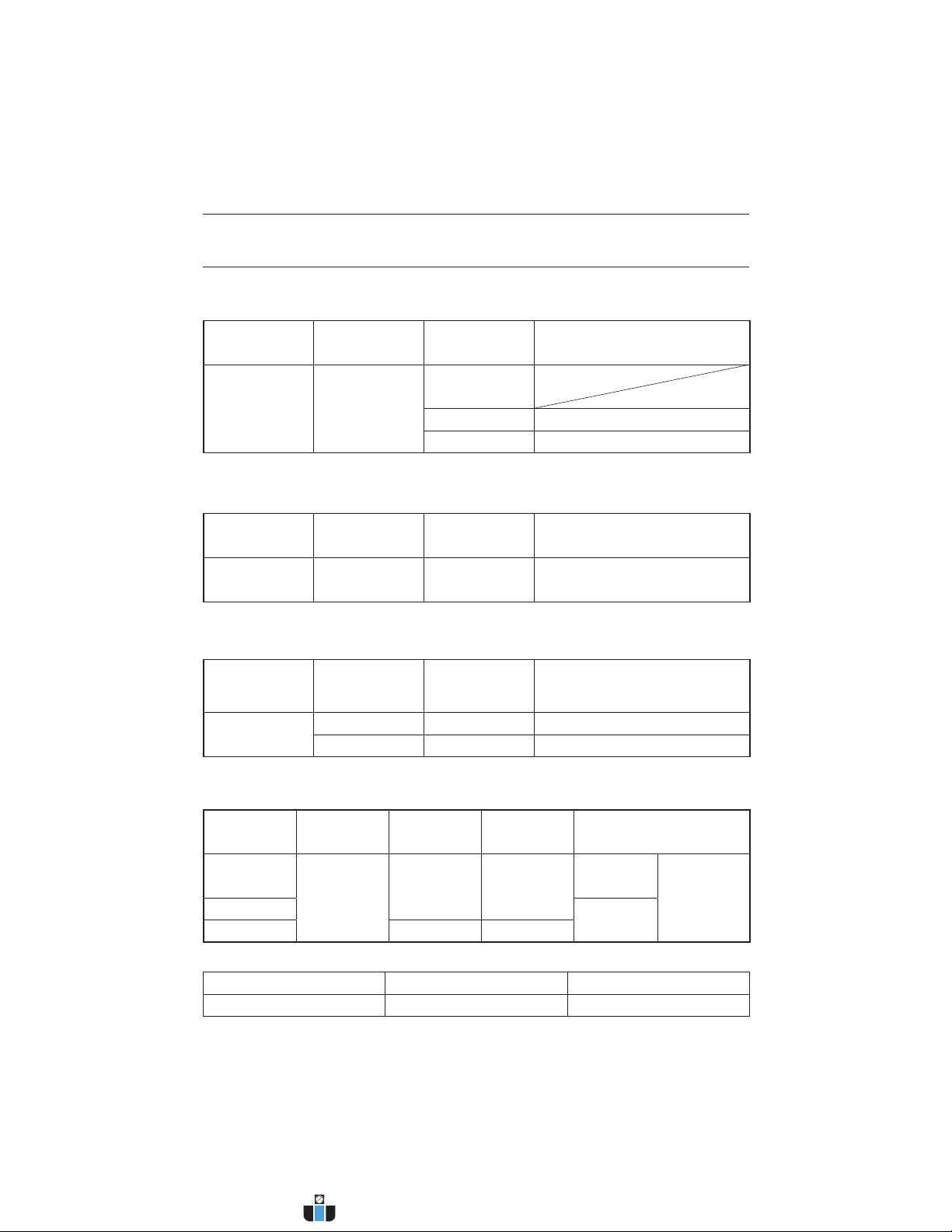

3.Specification .................................................................................. 6

4.Continuity (resistance) tests .......................................................... 9

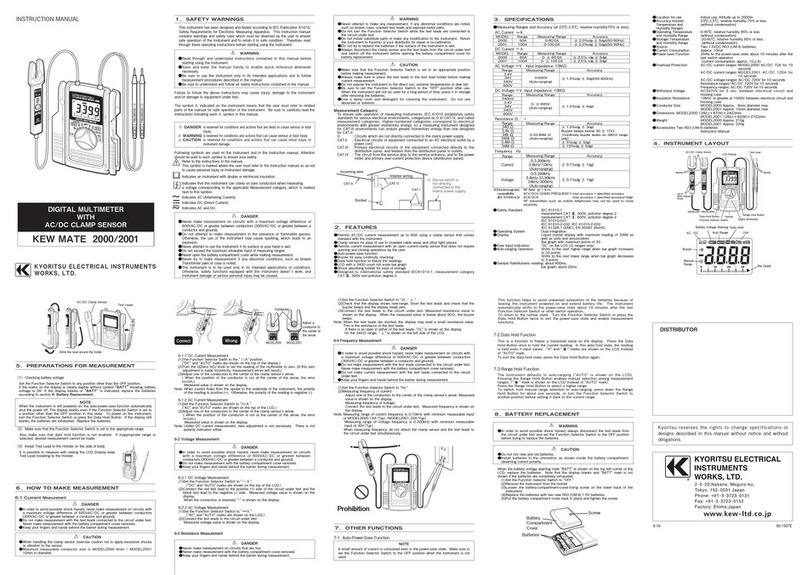

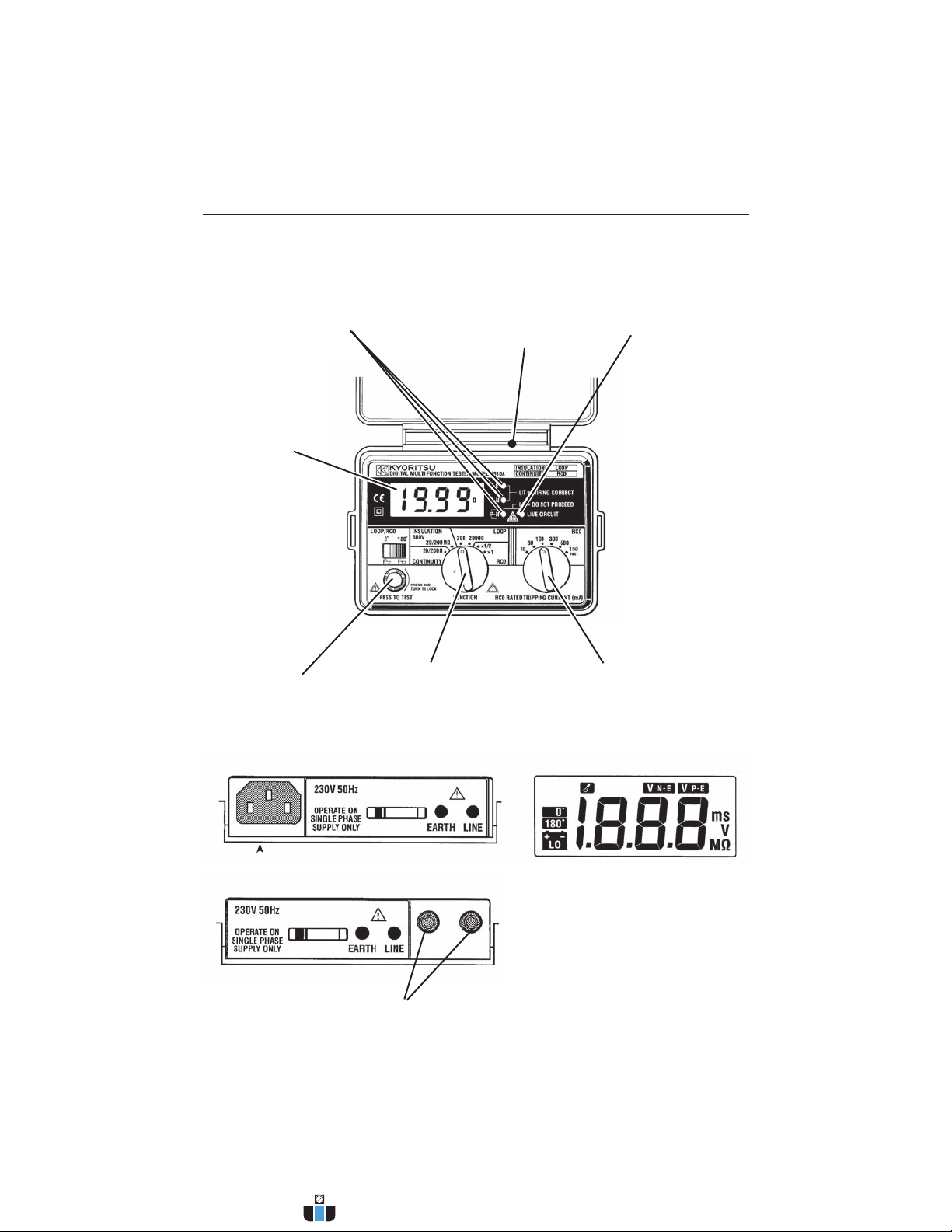

4.1

Instrument layout ................................................................. 9

4.2

Resistance of test leads ....................................................... 9

4.3

Continuity testing ............................................................... 10

5.Insulation Tests ........................................................................... 11

5.1

The nature of insulation resistance .................................... 11

5.1.2

Capacitive current .............................................................. 11

5.1.3

Conduction current ............................................................ 12

5.1.4

Surface leakage current ..................................................... 12

5.1.5

Total leakage current ......................................................... 13

5.2

Damage to voltage-sensitive equipment ............................ 13

5.3

Preparation for measurement ............................................ 14

5.4

Insulation resistance measurement ................................... 14

6.Loop Impedance Tests ............................................................... 17

6.1

Voltage measurement ........................................................ 17

6.2

What is earth fault loop impedance? ................................. 17

6.3

Automatic over-temperature cut-out .................................. 17

6.4

The loop impedance test ................................................... 18

6.5

Loop impedance at 3 phase equipment ............................. 19

7.RCD Tests ................................................................................... 21

7.1

Purpose of RCD Test ......................................................... 21

7.2

What does the RCD test really do? ................................... 21

7.3

RCD testing ....................................................................... 21

7.4

Testing RCDs used to provide supplementary protection .. 22

7.5

Testing time delayed RCDs ............................................... 22

8.General ....................................................................................... 23

9.Battery replacement .................................................................... 24

10.Fuse replacement ....................................................................... 24

11.Servicing ..................................................................................... 25

12.Case, strap and shoulder pad assembly ..................................... 26

CONTENTS

5

10

15

20

25

30