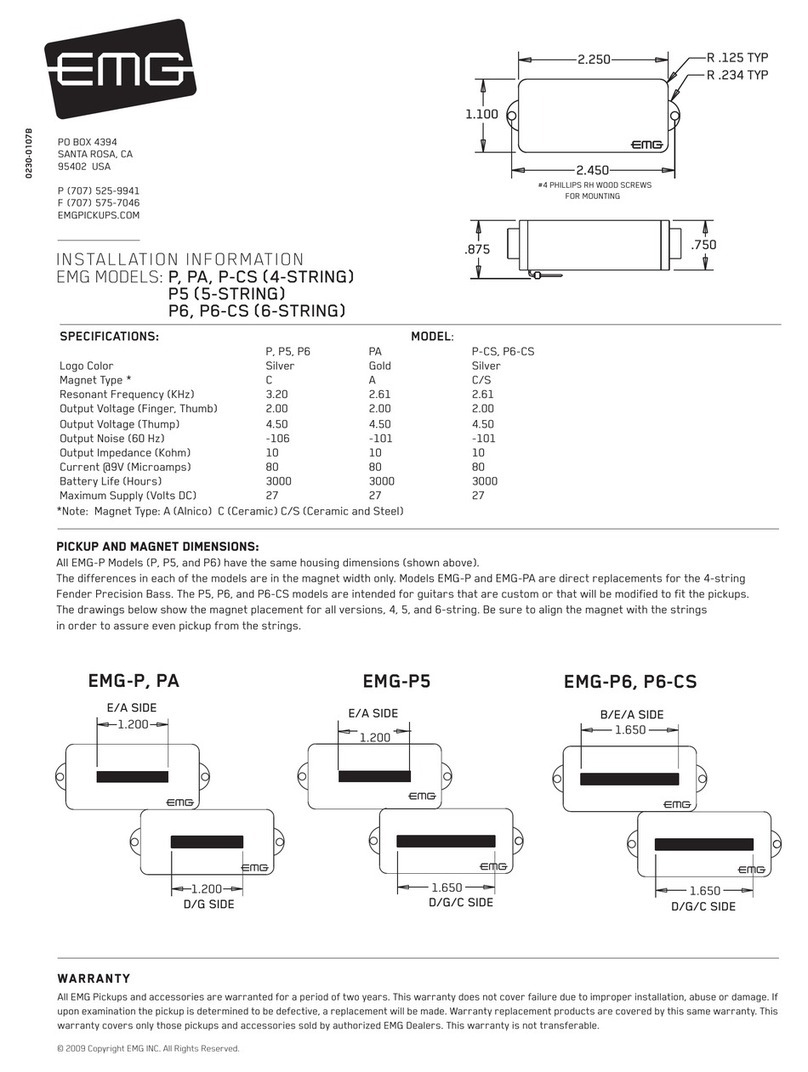

PICKUP INSTALLATION

Notes: For optimum performance of the Element pickup, the bridge slot must have a

perfectly at surface, free from high spots and loose debris. The slot depth should be

3/16” (.187”) or deeper. The commonly known 50/50 rule applies: “The amount of saddle

visible above the bridge surface (with pickup installed) should be no greater than the

amount of saddle in the slot beneath the bridge surface”.

The bottom surface of the saddle must also be perfectly at to establish even contact

along the pickup between the saddle and the slot! This can be accomplished by sanding

against a machined surface using ne grit sandpaper.

Installation: Remove the strings from the guitar. For guitars having a pickup installed for

the rst time you will need to compensate for the thickness of the pickup by removing

.030” from the overall saddle height. One simple method of accomplishing this is as

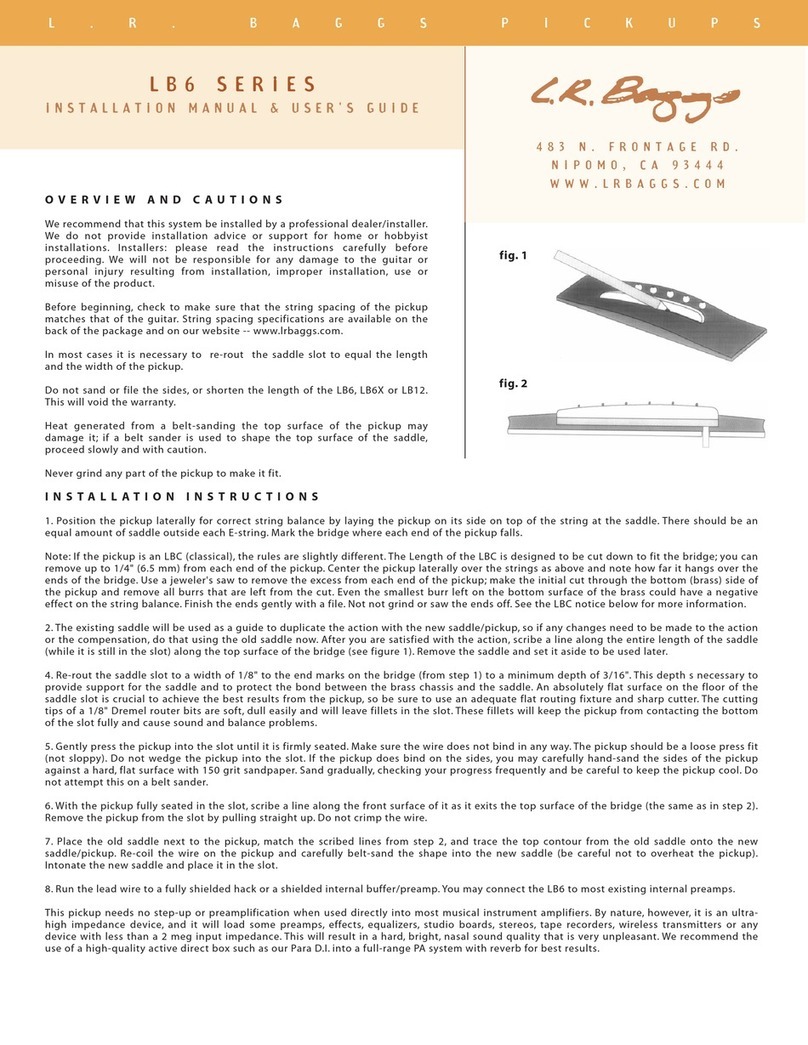

follows: Using a freshly sharpened pencil, scribe a line along the front edge of the saddle

where it extends above the bridge, see Fig 1.

This line will be used later as a guide when removing material from the bottom of the

saddle. (Details to follow)

Now remove the saddle to drill a hole for the pickup. Use a drill bit that is the same size as

the width of the saddle slot, generally between 3/32” and 1/8”.

Just before you drill, inspect the underside of the bridge inside the guitar and note the

position of the braces in relation to the saddle slot. It’s helpful to use the bridge pin holes

for visual reference. You may drill the hole at either end of the slot but be sure to position

the hole at the extreme end of the slot and drill at an angle if possible, as seen in Fig 3A.

Last, choose the side of the slot which allows you to drill without damaging a brace as you

penetrate the top, then proceed to drill. Remove any splintering left from the bit with a

small le or razor blade, then blow out the slot with compressed air and check for

remaining debris.

Feed the pickup into the slot from inside the guitar. Inserting a toothpick into the hole from

the outside of the guitar helps with nding the hole on the inside. There is a black dot on the

end of the Element pickup, which should be facing up when the pickup is laid in place.

Important: The t of the saddle is among the most crucial factors of this installation. The

saddle should t loosely enough in the slot that it can be pulled out easily (using only

your ngertips) with just the slightest amount of drag. If the saddle binds at all in the slot,

sand it down just a bit against a at surface with 220 to 320 grit sandpaper until it goes in

and out with ease. A saddle that binds on the walls of the slot won’t be able to make

thorough contact with the pickup and will cause the pickup to malfunction. A saddle

which is excessively loose will lean forward under pressure, creating uneven contact on

the pickup, Fig 2A, which will most likely result in poor performance.

The best remedy for a very loose saddle is to make a new properly tting saddle, Fig 2B.

However, you can also shim the saddle thickness with tape until it ts correctly or even

sand an intentional tilt into the saddle’s bottom surface so that when it leans forward it

makes even contact on the pickup, Fig 2C.

Compensating for the thickness of the pickup: Lay the saddle over the pickup in the

slot and observe the scribed line from Fig 1. The distance between the bridge top and the

line is the amount of material you’ll need to remove from the bottom of the saddle. Sand

the bottom surface of the saddle on a belt sander until the scribed line is just above the

bridge top.

A belt sander is not capable of creating a truly at surface; therefore, it is necessary to

complete sanding the bottom of the saddle by hand. It is best to do this against a

machined at surface with ne sandpaper. Use a straight edge with a strong light source

to inspect the atness of your saddle.

When nished, make sure the pickup extends all the way to the far end of the slot, place

the saddle on top of it and temporarily secure it with a piece of tape. Secure the pickup

wire with a wire clip (provided) about 1 ½” from the exit hole on the edge of the bridge

plate, with a 1 to 2 inch service loop, Fig 3A & 3B.

Fig. 1

Fig. 2A

Fig. 2B

Fig. 2C

Before

After

Fig. 3A – Back view

Fig. 3B – Side view