The illustrations and data used in the manual were current at the time of printing, but the

Z-Spray may vary slightly due to ongoing engineering changes. L. T. Rich Products, Inc

reserves the right to implement engineering and design changes to the Z-Spray as may be

necessary without prior notification.

2.2 Safety Guards and Covers

Safety is a primary concern in the design and manufacturing of all L. T. Rich Products.

Unfortunately, our extensive efforts to provide safe equipment can be negated by a single

careless act of an operator. In addition to the design and configuration of the Z-Spray,

hazard control and accidents prevention are also dependent upon the awareness,

condition, maintenance, and storage of the Z-Spray. THE BEST SAFETY PRACTICE IS

AN INFORMED, CAREFUL OPERATOR!!

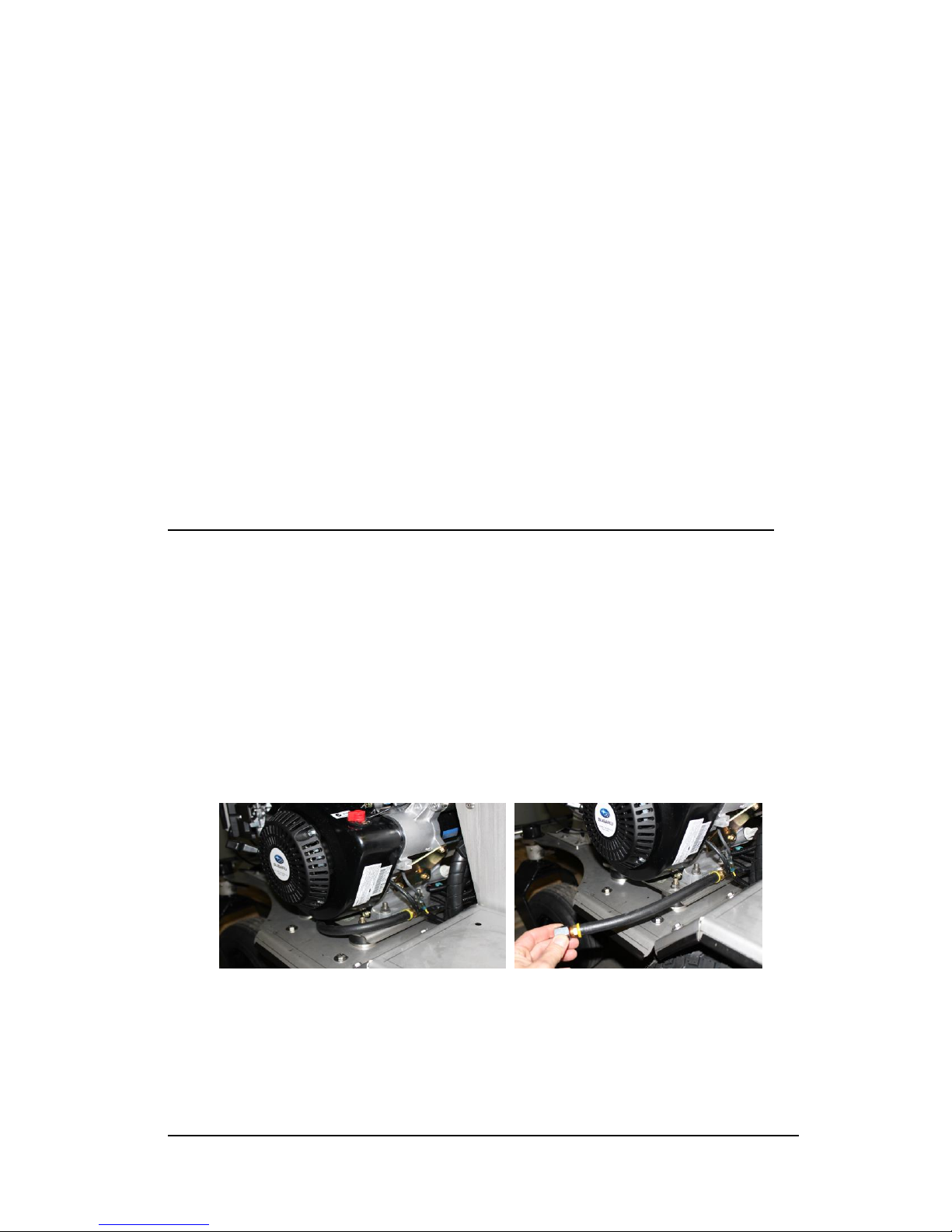

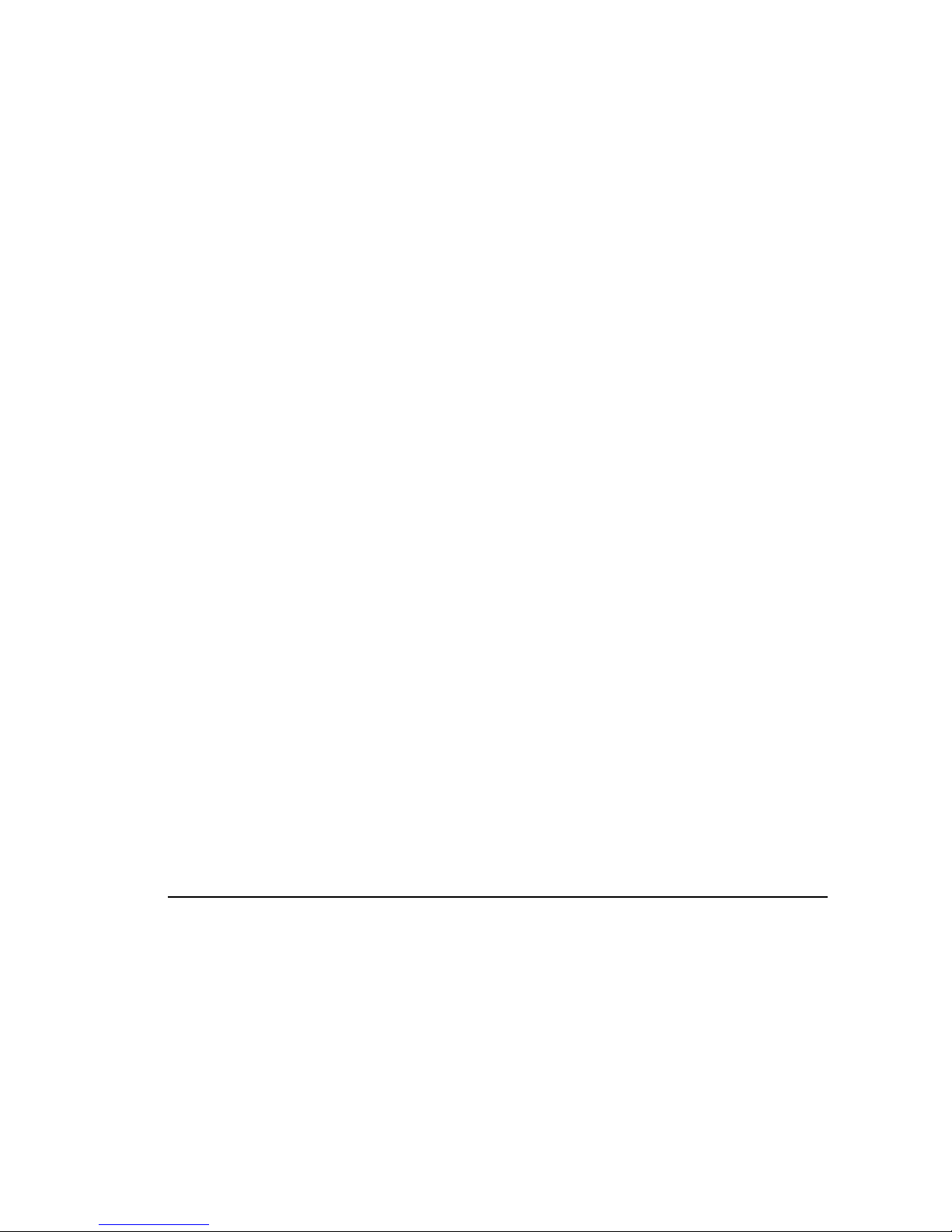

Safety guards are mounted on the backside of the Hydro-Gear Pumps (at the shin level of

the operator). These guards are designed to cover the hydraulic belt under the base and

protect the operator. Removing this guard could cause injury to an operator and could

void the Z-Spray’s warranty. Remove this guard ONLY when unit is turned off to do

preventative maintenance.

2.3 Operational Safety Rules

Never operate the Z-Spray without all covers, shields, and safety devices installed and

secured.

Never permit any person other than the operator to ride or board the Z-Spray at any time.

NEVER ALLOW RIDERS!!!

Use extreme care and maintain minimum ground speed when transporting on a hillside or

over rough ground, and when operating close to ditches, fences, or water.

The owner/user can prevent and is responsible for accidents or injuries occurring to

himself or herself, other people.

Operate only in daylight or good artificial light (min 200 lux).

Never allow anyone near the Z-Spray while in operation.

Only operate machine from the operator’s platform (Foot Pan), never operate machine

when standing on the ground.

Be alert for holes in the terrain as well as any other hidden hazards. Always drive slowly

over rough ground.

Never operate this machine on slopes exceeding 15 degrees in any direction. NOTE: To

operate on terrain that exceeds these limits constitutes misuse of the equipment and as such,

any and all injuries as a result of said use are expressly disclaimed.

2.4 Maintenance Safety Rules

Never perform maintenance on the Z-Spray when children are present.

Never allow anyone near the operation controls while performing service or maintenance

to the Z-Spray.

Keep the Z-Spray engine area free of accumulated debris, fuel, or excess grease and oil to

prevent fire hazard.

Page 3