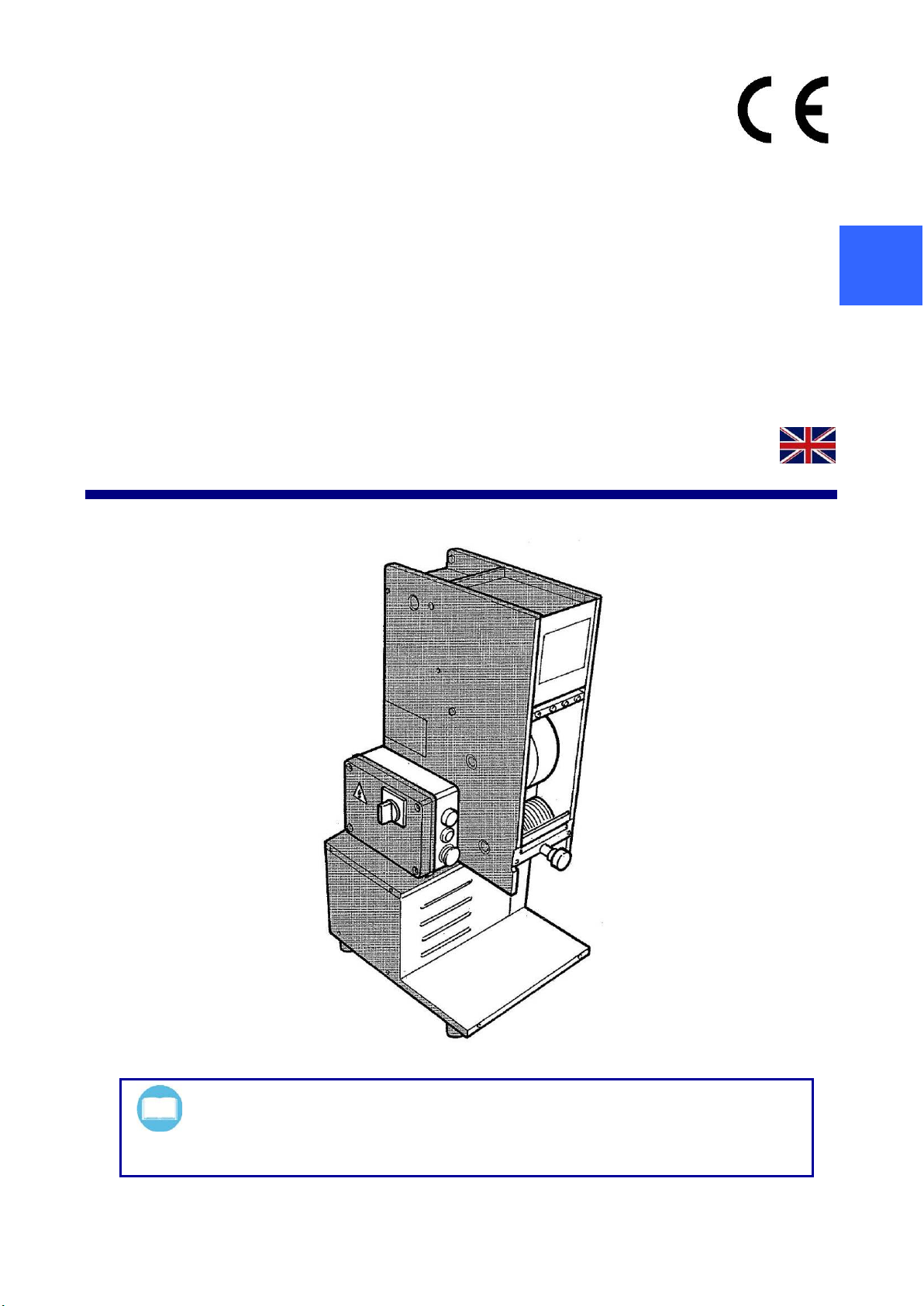

Machine description IMPERIA & MONFERRINA S.p.A.

6 G2

If the claim proves to be unjustified, all repair and/or part replacement

costs shall be borne by the customer.

The guarantee certificate and the carriage note/invoice must be shown to

the technical personnel carrying out repairs or must accompany the

machine sent for repair.

The guarantee is not extended following technical work performed on the

machine. Repairs are carried out at our “Technical Assistance Centre” at

our works and the part/s involved must arrive with carriage paid (carriage

expenses borne by the customer unless agreed differently).

The guarantee does not however cover: accidental damage, in transport,

through negligence or inappropriate treatment, incorrect use not

conforming with notes shown in the instructions booklet and anyway

caused by phenomena not depending on the regular functioning or use of

the machine.

The IMPERIA & MONFERRINA S.p.A. company declines all

responsibility for any harm to persons or damage to property arising from

bad or imperfect use of the machine.

Professional qualifications of persons enabled to operate on the machine

The machine is to be used only by authorised persons who have been

instructed for the purpose; the same precaution is valid for the persons

who shall carry out the maintenance. Do not permit unauthorised persons

to approach the machine when running or during maintenance.

After receiving all the instructions necessary, only the following

professional operators are permitted to work on the machine:

Safety officer

The safety officer is responsible for protection and prevention of risks in

the company, as specified in the European Directive 89/391 EEC (Safety

in the workplace), acknowledged in Italy by D.L. Executive Order of

12/11/1994.

The safety officer shall ascertain that all the persons operating on the

machine have received all the relevant instructions contained in this

handbook.

Operator (in charge of running the machine)

Trained operator qualified to run the machine (work cycle, any

adjustments, etc.).

This operator shall only carry out the operations specifically assigned and

described in this handbook.

It is most important to avoid that the machine is not used by unskilled

persons.