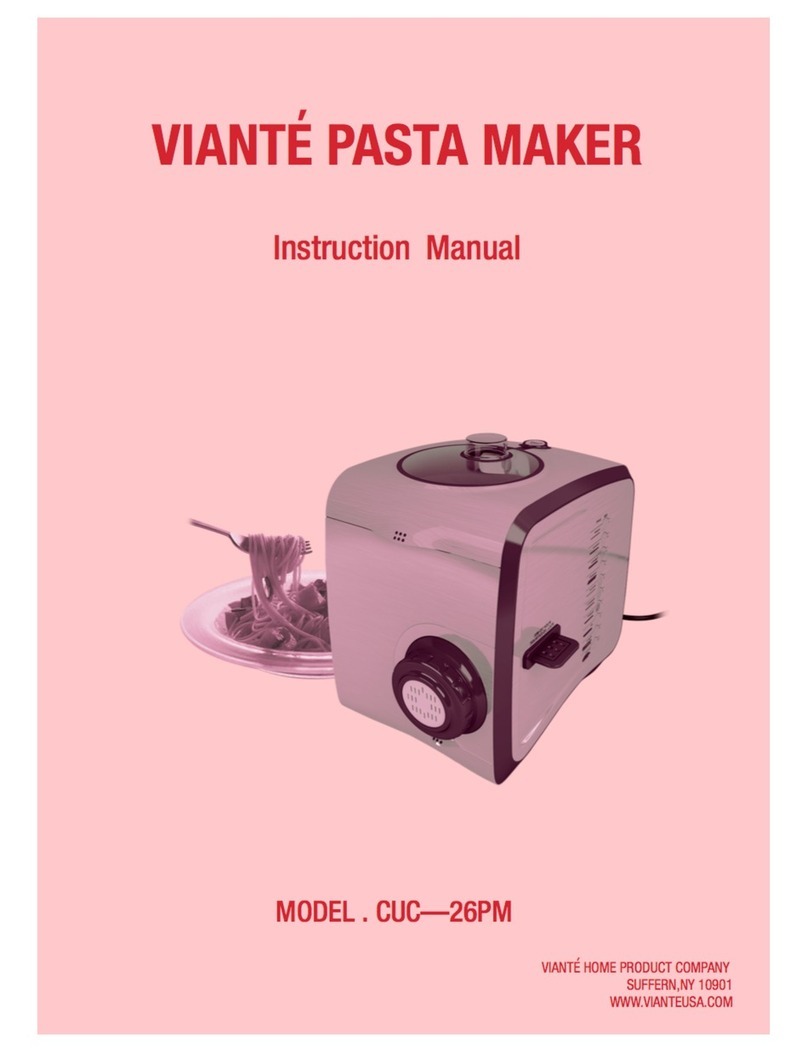

Operating Instructions

If you have not already reviewed the assembly instructions please refer to Assembly Instructions before proceeding.

Ensure the Power Switch is in the ‘OFF’ Position before continuing.

Open the mixing bowl lid. Add the dry ingredients from your recipe to the mixing hopper.

Close the mixing hopper lid and switch the Power Switch to ‘ON’ and after ensuring it is safe to begin mixing the dry

ingredients turn the selection switch to “Mix” (left) and press the ‘Start’ button on the side of the machine.

If multiple types of flower have been added allow additional time for the ingredients to mix prior to adding water.

Using the open slots through the Mixing Bowl Lid slowly pour the pre-measured water into the mixing hopper.

Allow the ingredients to mix for the period of time described in the recipe.

Once the ingredients have mixed for the allotted time period in the recipe, press the ‘Stop’ button located on the front panel

of the machine and open the mixing bowl lid to inspect the dough mixture.

Mixing generally takes 15-18 minutes. Keep in mind that all liquids should be added during the first 3-5 minutes. Adding

liquid after this time may produce unwanted results, because the flour will not completely absorb the liquid causing the dough

to be sticky or clumpy.

If the ingredients require further mixing reinstall the mixing bowl lid, switch the Power Switch to ‘On’ and press the ‘Start’

switch to continue mixing.

At the end of the mixing process the pasta dough should be the size of coffee beans. If the pasta dough turn into a big clump

of dough it means that too much liquid was added. In this case it is better to start over again. If on the contrary, the flour

does not form into the shape of beans you may try adding liquid, but in either case it may be easier to start over again

.

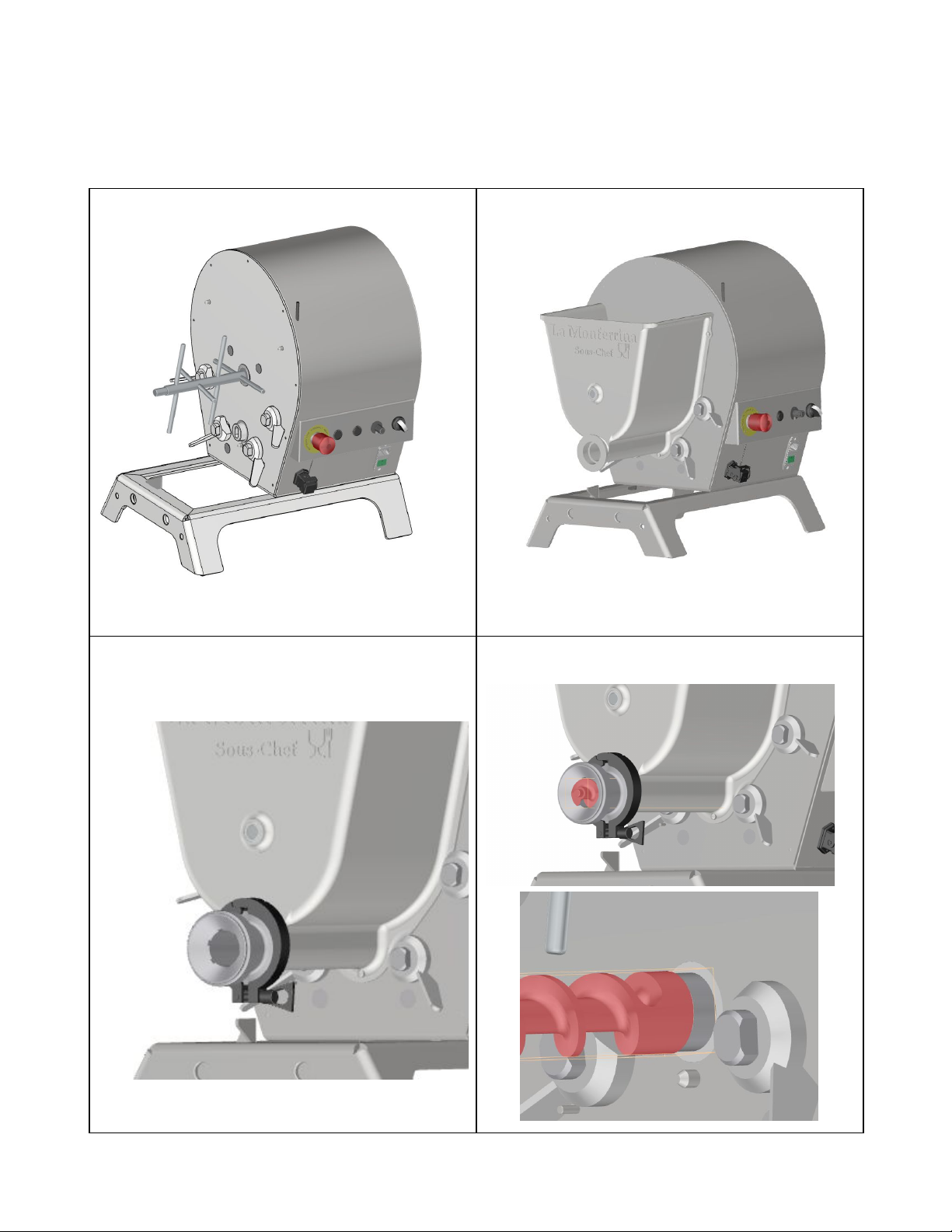

When the dough is ready to be extruded it should look similar to the picture below. To begin the extrusion process turn and

hold the direction knob to the ‘Extrude’ position and press the ‘Start’ button. After several seconds the dough will begin to

extrude from the die.

To stop the machine at any time use the ‘Stop’ Button.

Never place hands or tools inside the mixing bowl unless the

machine's power switch is in the ‘OFF’ Position.

Once the mixing bowl is empty the extrusion process is completed. Stop the machine by pressing the ‘Stop’ button and turn

the power switch to the ‘OFF’ Position.

Cleaning procedures continued on the next chapter

8