MANUAL LMDG 200

2

TABLE OF CONTENTS

1. SAFETY INFORMATION........................................................................................3

1.1. WARNING SYMBOLS..........................................................................................3

1.2. SAFETY INSTRUCTIONS....................................................................................3

2. GENERAL DESCRIPTION......................................................................................5

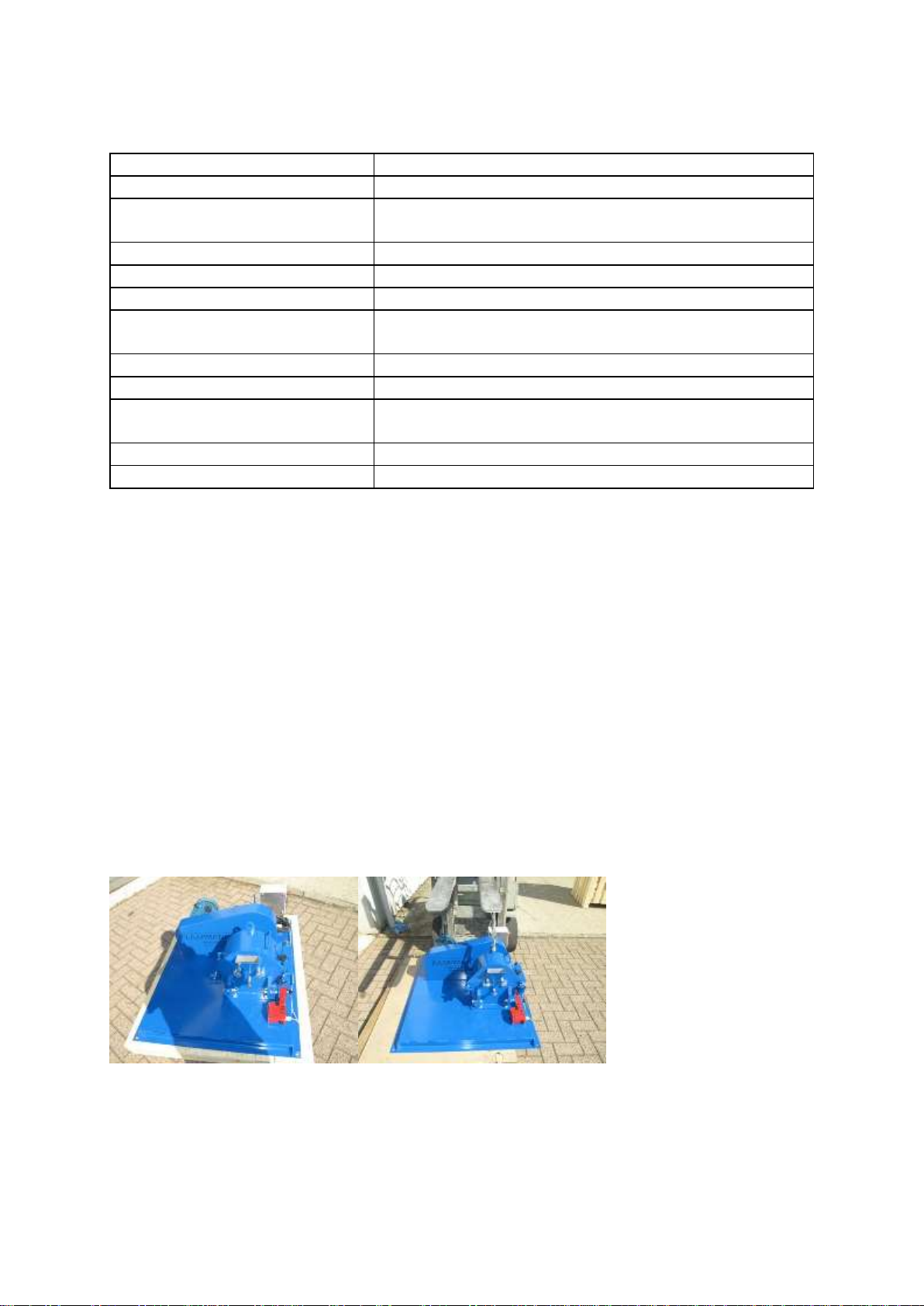

3. TECHNICAL FEATURES........................................................................................6

3.1. CONSTRUCTION.................................................................................................6

3.2. TECHNICAL DATA...............................................................................................6

4. INSTALLATION ......................................................................................................7

4.1. UNPACKING........................................................................................................7

4.2. SELECTING THE RIGHT PLACE ........................................................................7

4.3. CONNECTING THE POWER CORD ...................................................................7

4.4. ENVIRONMENT CONDITIONS............................................................................7

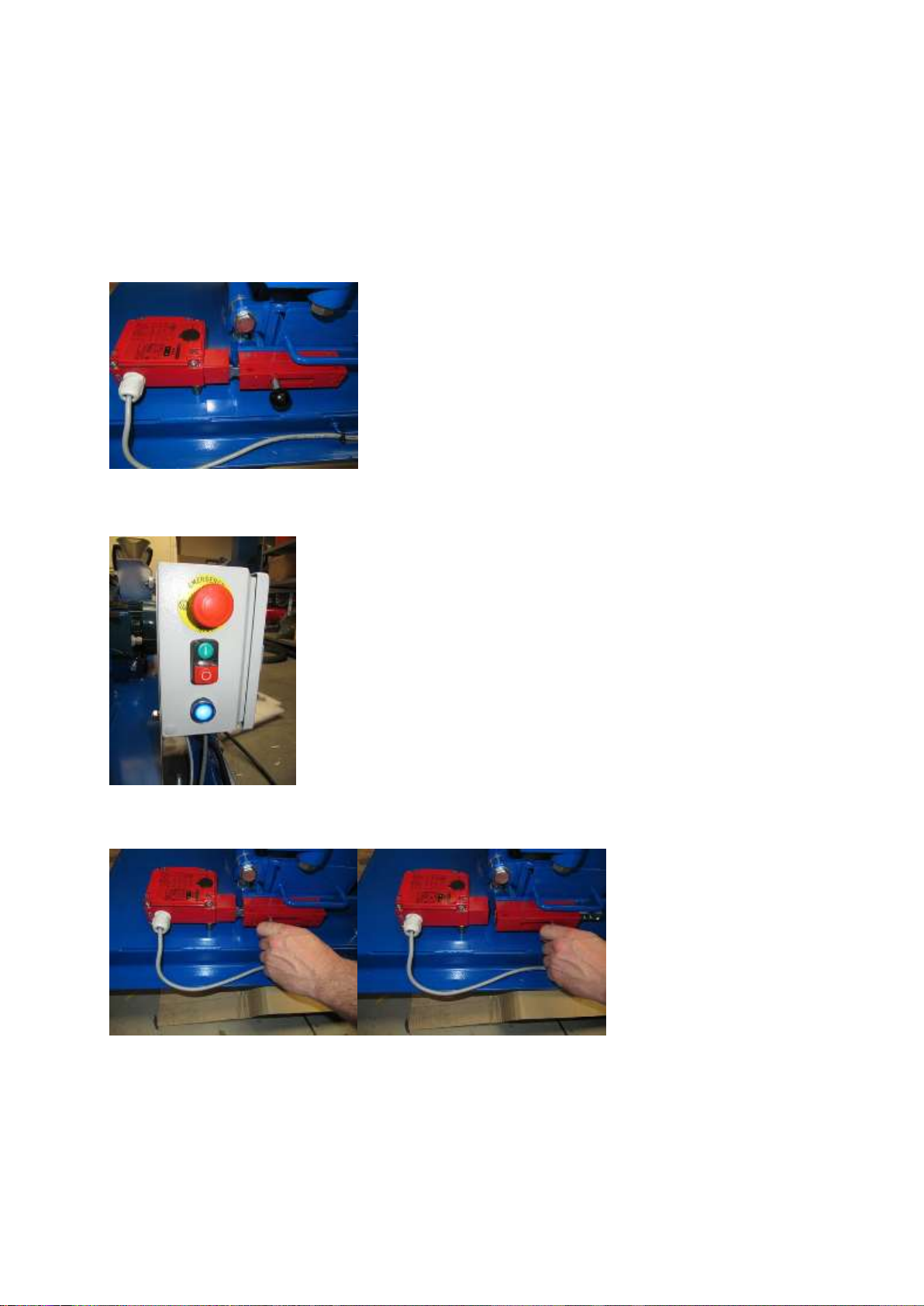

4.5. TURN THE SAFETY SWITCH IN THE RIGHT DIRECTECTION.........................8

5. INSTRUCTIONS FOR USE.....................................................................................9

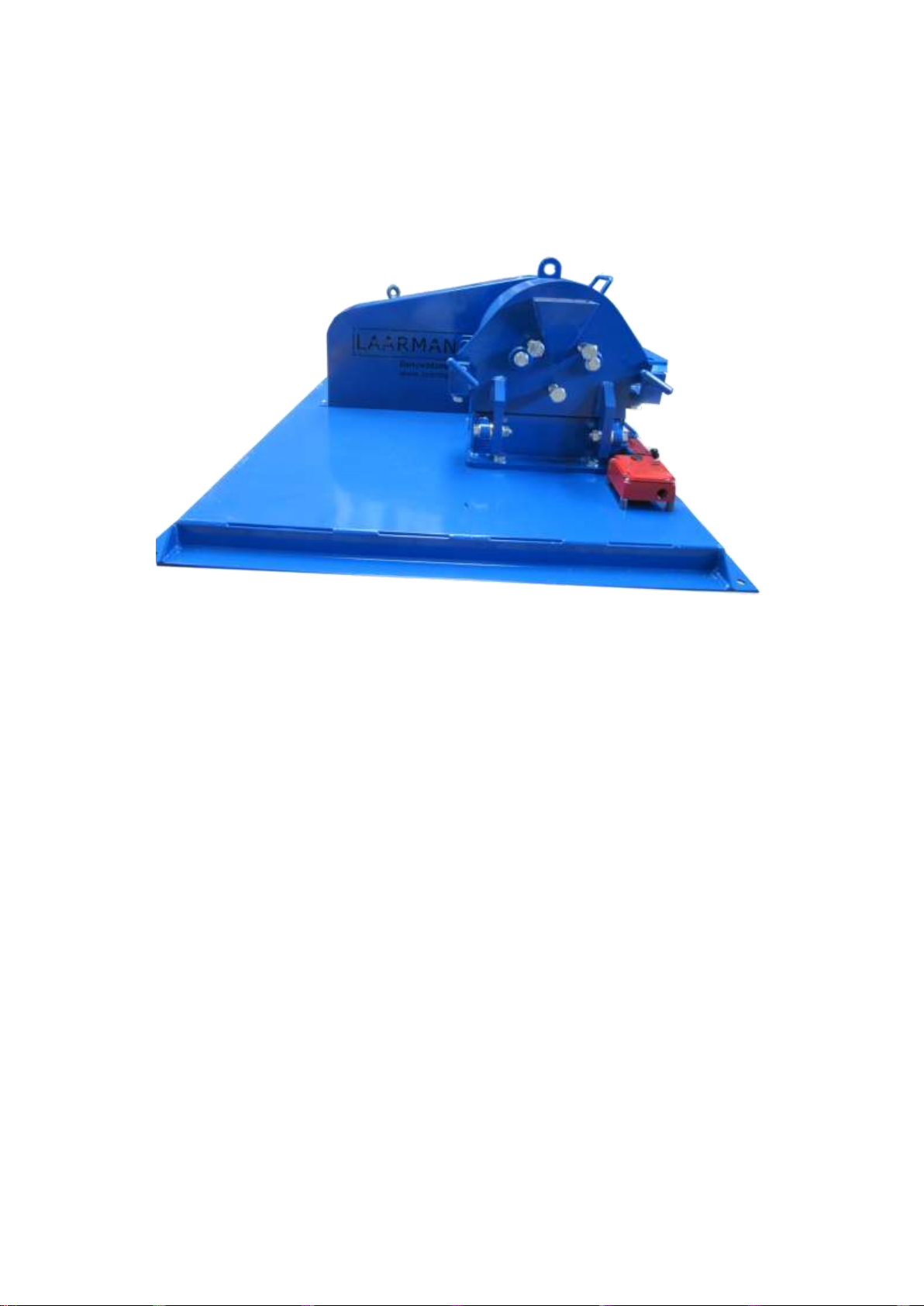

5.1. OVERALL VIEW...................................................................................................9

5.2. DESCRIPTION STOP / START FUNCTION......................................................10

6. WORKING INSTRUCTIONS.................................................................................14

6.1. GENERAL ..........................................................................................................14

6.2. STARTING THE MILLING PROCESS................................................................14

6.3. STOPPING THE MILLING PROCESS...............................................................14

7. TROUBLESHOOTING..........................................................................................15

8. MAINTENANCE....................................................................................................15

8.1. WEAR.................................................................................................................15

8.2. CLEANING.........................................................................................................15

9. EXPLODED VIEWS AND PART LISTS................................................................16

10. CE CERTIFICATE...............................................................................................22