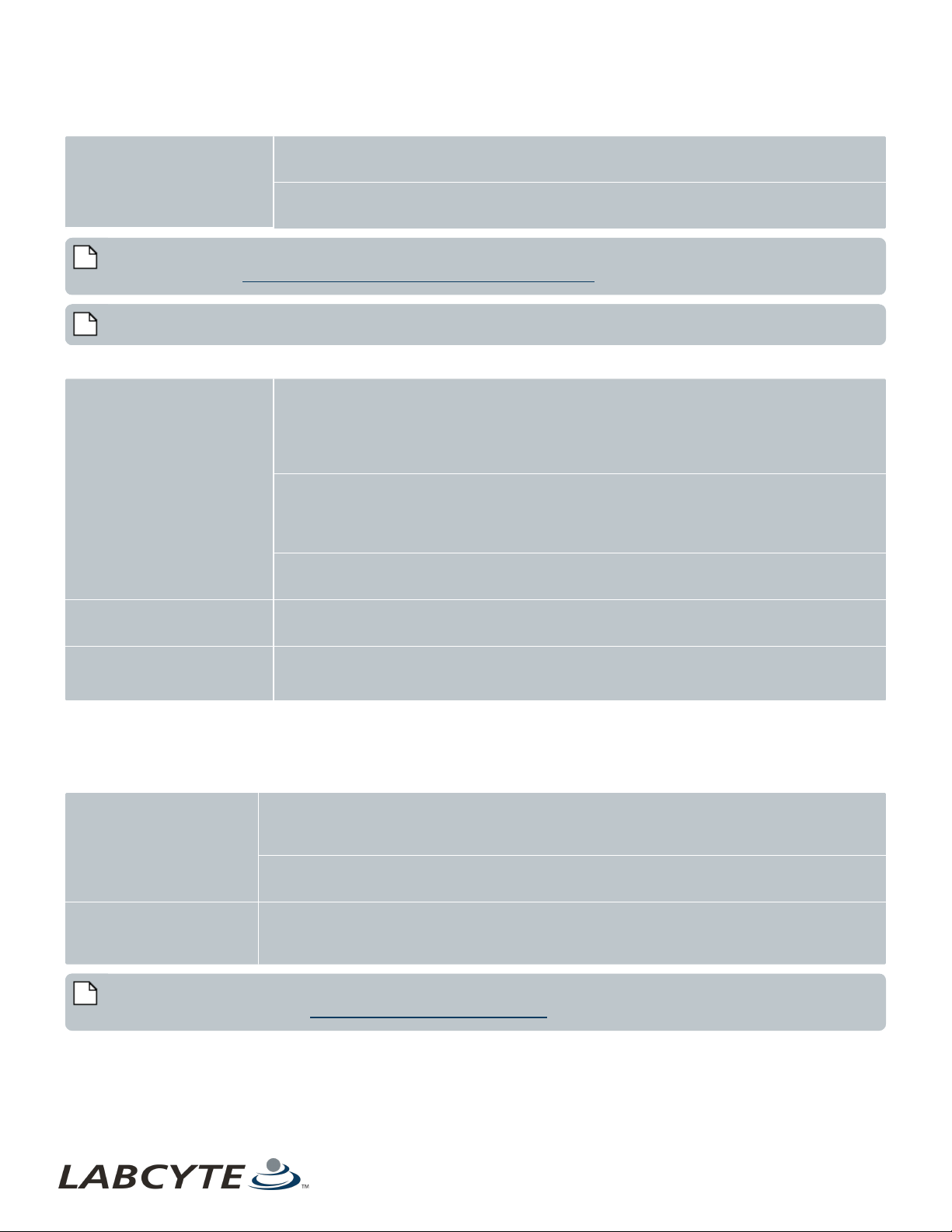

Vacuum source for source

plate dryer (2 options)

Option 1: House supply. Minimum 200 Torr (266 mbar, 22 in Hg Vac) minimum pumping speed

8.0 m3/hr

Option 2: Standalone vacuum with surge tank (10 L). 100 Torr (133 mbar, 26 in Hg Vac),

minimum pumping speed 2.0 m3/hr

Note: A standalone Vacuubrand MZ 2S-NT vacuum system can be purchased from Labcyte (Part #001-8104). For more

information, see the Vacuum Pump (Optional and sold separately by Labcyte) topic.

Note: The 10 L surge tank comes standard with the Echo Liquid Handler to ensure consistent vacuum.

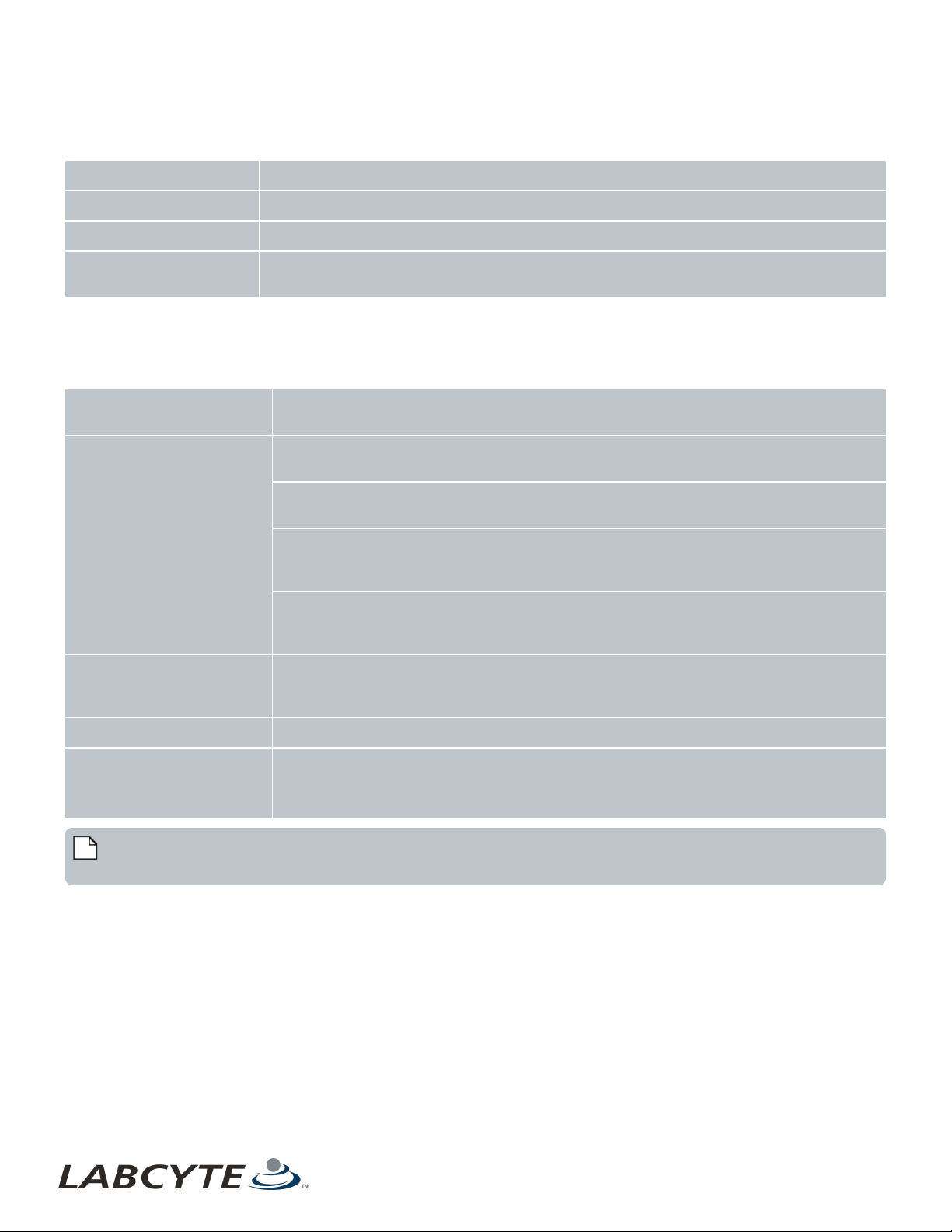

Instrument mounting surface

(minimal requirements)

The Echo Liquid Handler can emit vibration while in operation and is susceptible to vibration

from other devices. For this reason, the Echo system should be placed on a surface that is

isolated from surrounding equipment or designed to suppress the transmission of vibration

from devices. The surface must be sturdy, level, and water-resistant with cross-bracing or

welded joints.

The surface must be capable of supporting a minimum of 142 kg (313 lbs) weight with

sufficient surface area to accommodate the Echo Liquid Handler in the recommended

operating envelope (see Echo Liquid Handler Dimensions). If the mounting surface is a table

top, the table legs should not rest on casters. If the table has casters, they should be locked.

If the chiller will be installed on the bench surface, it must accommodate an additional 14 kg

(31 lbs).

Destination plate samples At installation, ensure common destination plates to be used with the instrument are

available for tuning the destination plate gripper.

Coupling Fluid Use only ASTM D-1193 Type 1 water in the fluidics system

Coupling Fluid Temperature: 22.1°C ± 0.9°C (71.8°F± 1.6°F)

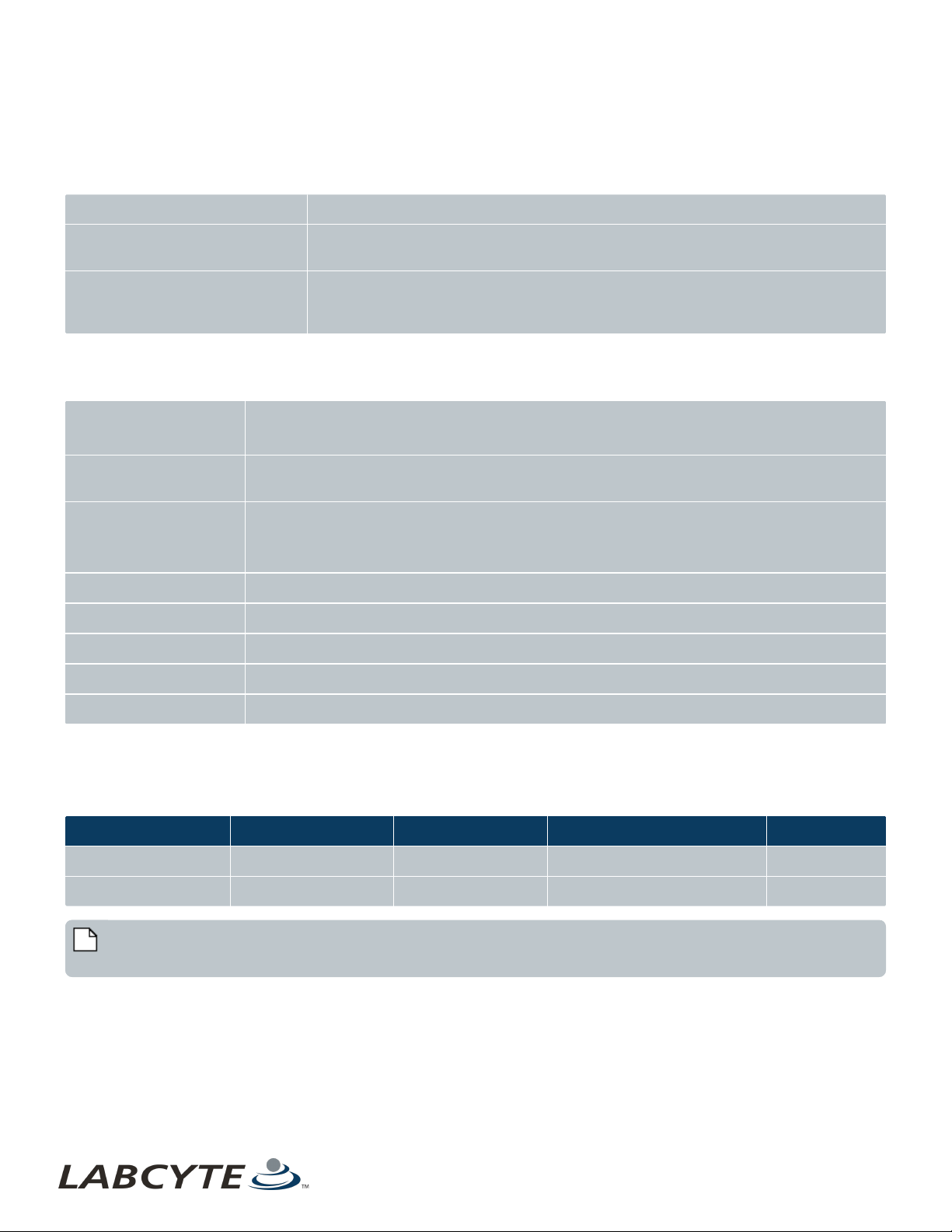

User Supplied Equipment Requirements

The user must provide the following items:

Hardware

Compressed air fitting compatible with 0.170 in ID / 0.250 in OD tubing between the compressed

air supply and the Echo Liquid Handler tubing (Labcyte provides the compressed air line and

fitting with the Echo Liquid Handler)

Vacuum fitting that connects 3/8 in ID, 5/8 in OD tubing to either house vacuum or a vacuum

pump. The supplied vacuum line is HercoBraid, 3/8 in ID, 5/8 in OD (RyanHerco P/N 0512-072)

Client PC

Minimum Requirements: Microsoft® Windows® 7 using 32- or 64-bit OS, or Microsoft® Windows®

10 64-bit; Intel® Core™ 2 Duo processor or later; 1GB of RAM or greater; 1 GB of available disk

storage; display resolution of 1280 x 1024 (1920x1020 preferred); 2 x Gigabit ethernet ports

Note: Client PC can be purchased directly from Labcyte (Part #ECHO-Client Computer). For information on the Client PC

available from Labcyte, see the Client PC (Sold separately by Labcyte) topic.

3

SITE PREP GUIDE | Echo® 650 Series Liquid Handler PN | 001-16480