6| LABNET MICROTUBE SHAKING INCUBATOR

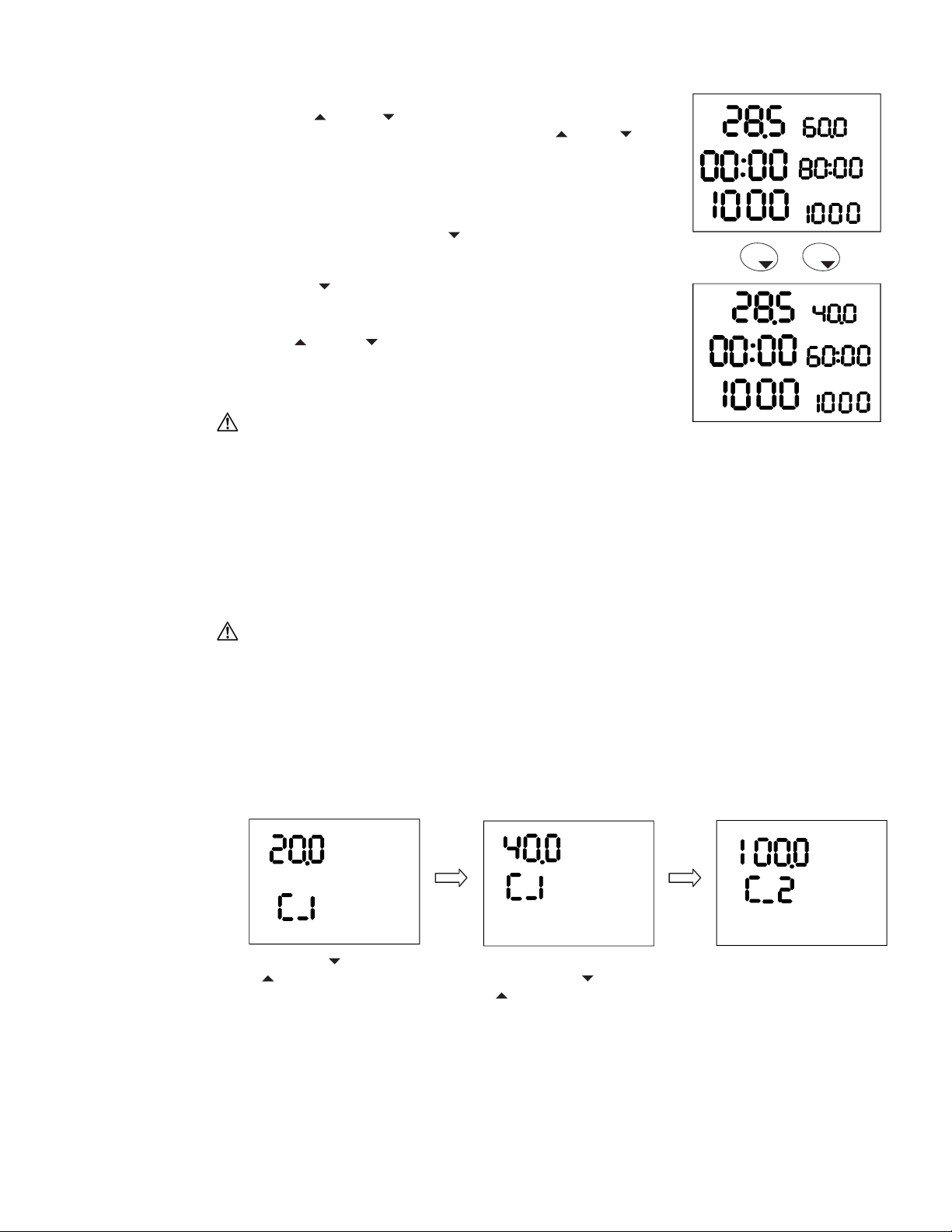

The digits of the TEMP display may be reduced or increased by

pressing Temp or Temp respectively. The digits of the TIME

display may be reduced or increased by pressing Time or Time

respectively.

Press the above mentioned buttons for more than 3 seconds to set

up the exact value.

If the temperature should be set at 40°C and the time should be

set up at 60:00, then press the Temp and not release to see the

number reducing. When the number shows 40.0, release the

button, and it will be automatically saved in 3 seconds. Next

press the Time and not release to see the number reducing.

When the number shows 60:00, release the button, and it will be

automatically saved in 3 seconds.

Press Speed or Speed to set up for the speed. The number will

increase or reduce at a rate of 50 rpm, release the button when the

number reaches exact value, and it will be automatically saved in 3

seconds. When set up is done, press Start/Stop to start mixing.

After the setting value of temperature is saved successfully, the device

will automatically heat or cool, to achieve the setting temp. point.

8.3 Pulse vibration

Press Short/Prog to start instant vibration or short term vibration. Press the button to start it and release

the button to stop it. The running speed of pulse vibration is the highest vibration speed.

8.4 Correct temperature discrepancy

The temperature of the instrument has been calibrated before shipment. However, due to various

conditions, there might be discrepancy between the actual temperature and displayed temperature.

On such case, you may use the calibration button to correct the discrepancy.

To ensure the accuracy of the temperature, please wait for at least 30 minutes after the instrument

is set at a constant temperature, and then perform the calibration.

Please use certified standard class two mercury thermometers to calibrate this instrument.

Calibration point: Center hole of the module. Please fill the hole with paraffin oil and immerge

the thermometer bulb in it.

The method of the temperature calibration of this instrument is two-point linear calibration.

The calibration point may be set freely, and by setting the second calibration point the same as the

first calibration point, you can adjust the calibration point to one temperature point. For two-point

calibration, if set the two points at 40°C and 100°C, then other temperature points will be automatically

adjusted per the linear relationship of the two calibration points.

TEMP

TIME

TIME

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TEMP

TIME

TIME

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TEMP

TIME

TIME

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

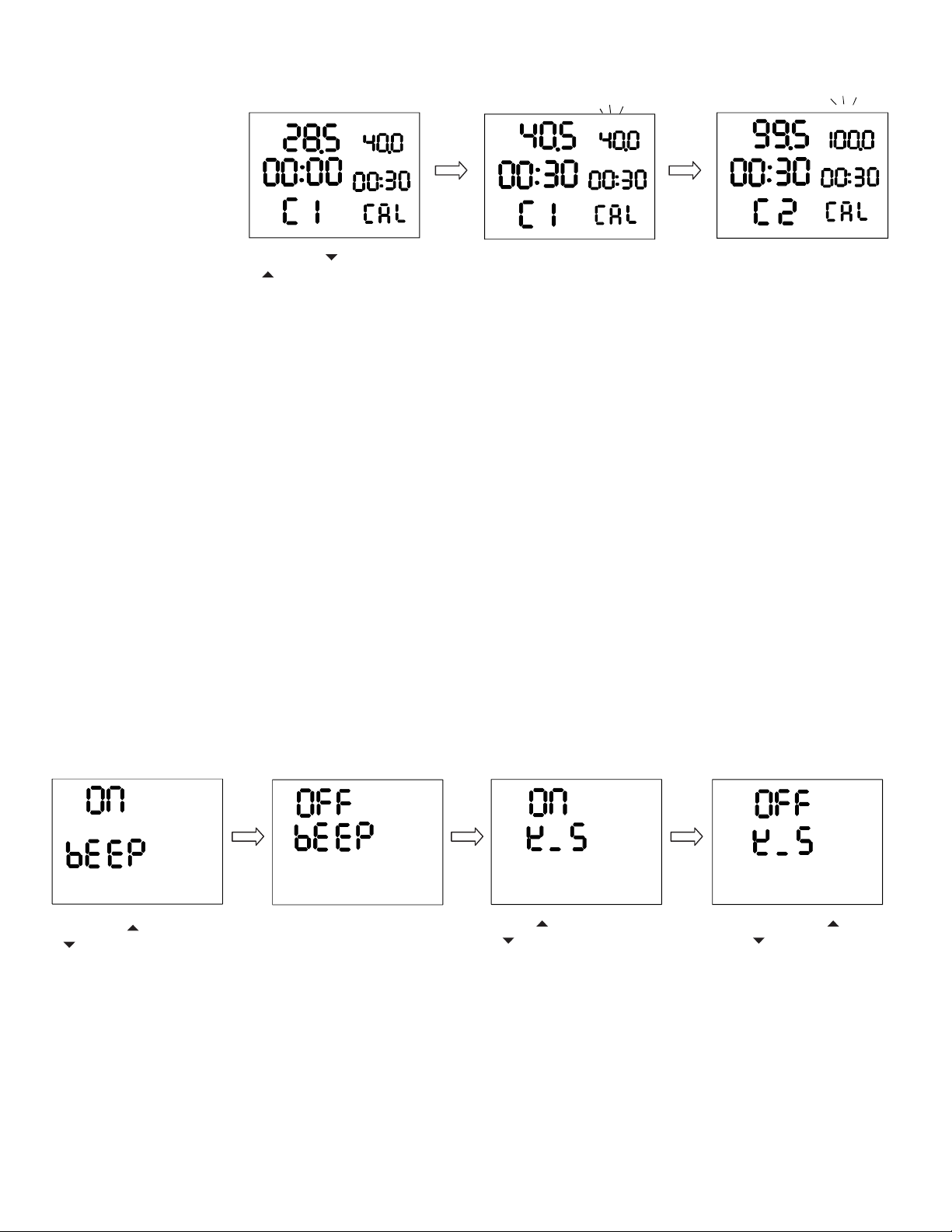

Press both Temp and

Temp at the same time,

and the display will show

the set up value of last

time (for example 20°C)

and the cursor of the first

calibration point, C_1.

Press the temperature

set up button Temp or

Temp to set up the first

calibration temperature

such as 40°C.

Perform the same

operation again to set up

the second calibration

temperature such as

100°C.

NOTE: When setting up the temperature points, an order of low temperature point first and high

temperature after is recommended. If on the case high temperature point is set first and low

temperature is set after, then when performing the following actual calibration, please follow the order

of low temperature first and high temperature after.

TEMP

TIME

TIME

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TIME

SPEED

TEMP

TIME

TIME

TEMP

TIME

SPEED

TEMP

TIME

SPEED

Temp

Time