LEGACY FG 033-0004 Page S.2 REV. 0/04-23-2007

Supplement–Legacy Fixed Gear

Lancair International Inc., Represented by Neico Aviation Inc., Copyright 2007 Redmond, OR 97756

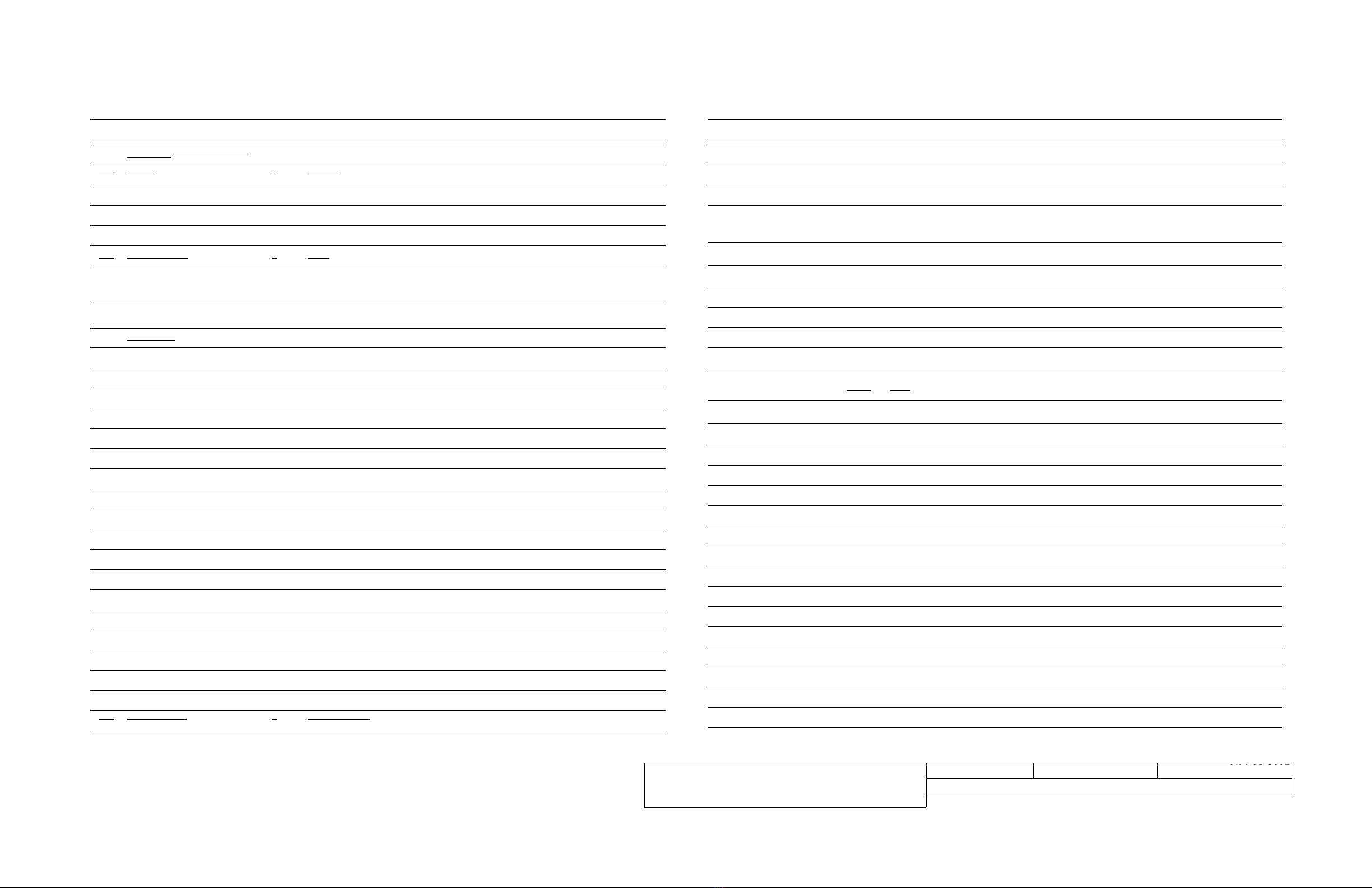

S.2 Parts Used in this Supplement

Aileron Idler

Item Part Number QTY Description

1) 209-0001 1 Bracket for aileron idler

2) 4581 1 Bellcrank assembly with bearing

3) AN3-11A 2 Bolt

4) AN365-1032A 2 Nylock nut

5) AN365-428A 5 Nylock nut

6) AN4-11 1 Bolt

7) AN4-11A 2 Bolts

8) AN960-416 7 Washers

9) CD315-12 4 Washers, special/tapered

10) F35-14 2 Rod-end bearing

11) MS24694-S104 4 Bolts (bracket to spar)

Composite parts for Wheel Pants and Fairings

Item Part Number QTY Description

1) 2044A 1 Nose gear leg fairing

2) 2044F 1 Nose gear fuselage fairing

3) 7043 2 Gear leg fairings

4) 7045 1 Nose gear pant

5) 7045L 1 Main gear pant, left

6) 7045R 1 Main gear pant, right

7) 7045LA 1 Main gear pant brake cover, left

8) 7045RA 1 Main gear pant brake cover, right

9) 7048L 1 Fuselage gear fairing, left

10) 7048R 1 Fuselage gear fairing, right

Nose Gear

Item Part Number QTY Description

1) 212-0041 1 Nut plate, nose fork

2) 212-0073 2 Plate, Keeper, Nose Gear

3) 229-0005 1 Link, Nose Gear

4) 432-0002 1 Nose Gear Cylinder

5) 433-0000 1 Nose Fork

6) 3455 1 Nose gear fearing mounting plate

7) 4717-01 1 Pivot Bearing Block, Left

8) 4717-02 1 Pivot Bearing Block, Right

9) 4717-03 2 Bearing

10) 4798 1 Spacer, Axle, Nose Wheel

11) 3326381K103 2 Nose Gear Bushings

12) 6381K103 2Bushing, Nose Gear

13) AN3-3A 4 Bolt

14) AN363-428 3 Lock Nut 1/4"

15) AN365-428 1 Nylock nut

16) AN365-528A 3 Nut, Nylock

17) AN4-23A 3 Bolt

18) AN426AD-4-4 8 Solid rivets

19) AN4-47A AN4-51 1 Bolt

20) AN5-17A 3 Bolts

21) AN960-10L 4 Washer, Lite

22) AN960-416L 8 Washer Thin

23) AN960-516 3 Washer, 5/16"

24) GM035-2 1 Nose gear wheel with bearings

25) GM035-2 1Nose gear wheel with bearings

26) GM038 2 Bushing, Axle, for nose wheel

27) K1000-5 4 Nut plates

28) AN960-516 MS20002C5 4Washers

29) AN5-11A MS21250-05013 2 Bolt

1/08-10-2007