3

INSTALLATION

Unpack the Dispenser

1. The Lancer dispenser is shipped in a corrugated shipping

carton.

2. Remove dispenser from corrugated shipping carton.

Tower Installation

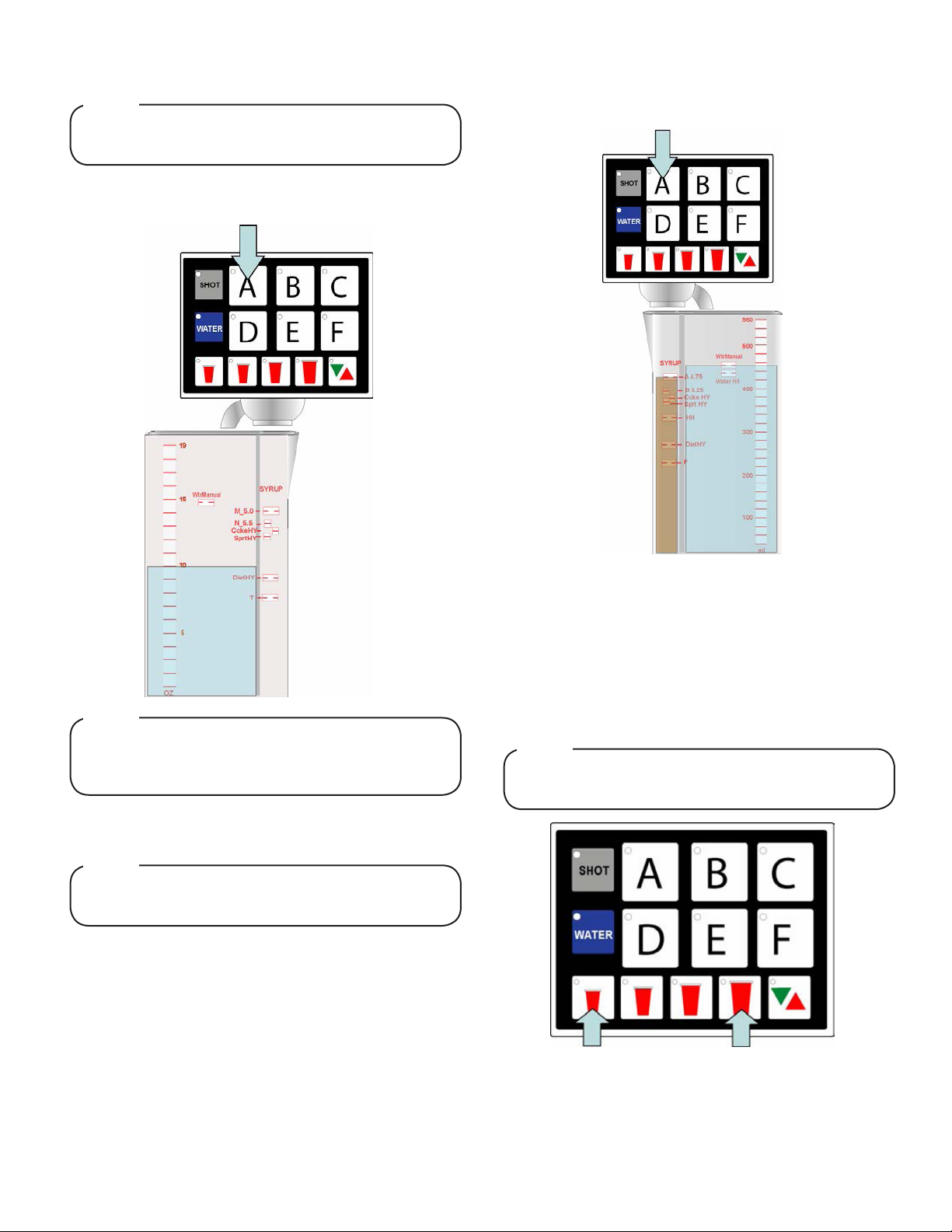

1. Route appropriate tubing from the water source to the plain

water inlet at tower and connect tubing to inlet using the

oetiker pliers and ttings,(see Plumbing Diagram on unit or

page 11 for reference).

Inspect unit for concealed damage. If evident, notify

deliveringcarrierandleaclaimagainstthesame.

NOTE

Selecting/Preparing Counter Location

1. Select a level, well ventilated location that is in close

proximity to a properly grounded electrical outlet, within ve

(5) feet (1.5 m) of a drain, a water supply that meets the

requirements shown in the Specications section found on

page 2, and away from direct sunlight or overhead lighting.

2. The dispenser is designed to be installed permanently to

a counter and must be sealed with a bead of clear silicone

caulk or sealant which provides a smooth and easily

cleanable bond to the counter.

The dispenser should only be installed in a location

where it can be overseen by trained personnel

NOTE

NSF listed units must be sealed to the counter or have

four (4) inch legs installed.

NOTE

To assure that beverage service is accessible to all

customers, Lancer recommends that counter height

and equipment selection be planned carefully. The

2010 ADA Standards for Accessible Design states that

themaximumreachheightfromtheoorshouldbeno

more than 48” if touch point is less than 10” from the

front of the counter, or a maximum of 46” if the touch

point is more than 10” and less than 27” from the front

of the counter. For more information about the

customer’s legal requirements for the accessibility of

installed equipment, refer to 2010 ADA Standards for

Accessible Design - http://www.ada.gov.

NOTE

In order to facilitate proper dispenser drainage, ensure

that the dispenser is level, front to back and side to

side. Place a level on the top of the rear edge of the

dispenser. The bubble must settle between the level

lines. Repeat this procedure for the remaining three

sides. Level unit if necessary. For optimum perfor-

mance place the unit at a 0° tilt. The maximum tilt is 5°.

Leveling the Dispenser:

3. Select a location for the remote chiller systerm, syrup

pumps, CO2 tank, syrup containers, and water lter

(recommended).

4. Cut out required opening in counter for the water/soda and

syrup lines in the designated dispenser location.

Unit is designed to be supported by a remote chiller

system or remote ice cooled system. Please see the

manufacturer’sspecicationsandinstructionsfor

installation.

NOTE

6. Connect drain line to tting at the bottom of the drip tray and

route to designated open type foor drain.

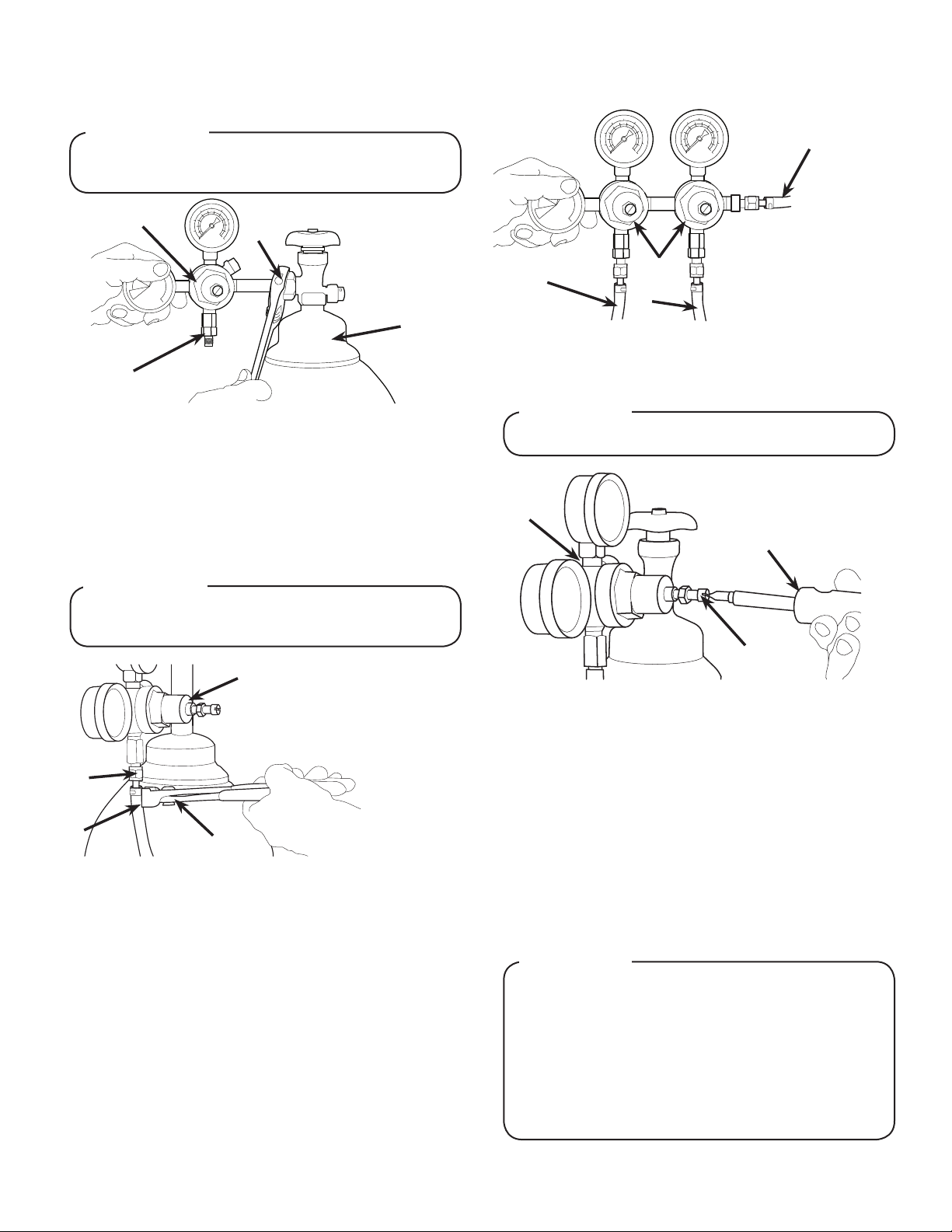

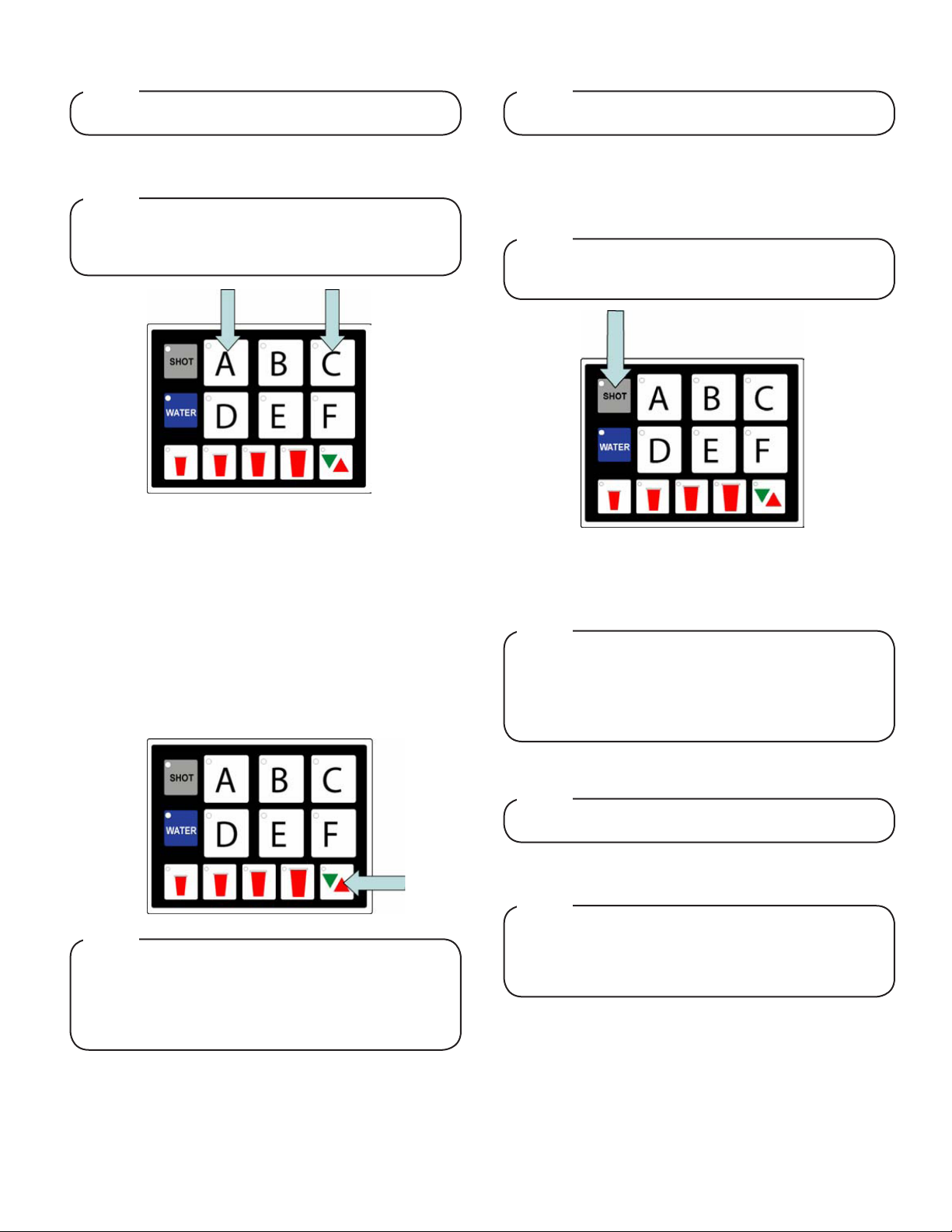

A

B

C

A. Oetiker Pliers

B. Fitting

C. Tubing

D. Syrup/Water

Inlet

D

DO NOT PLUG UNIT INTO GROUNDED ELECTRICAL

OUTLET AT THIS TIME. Make sure that all water lines

are tight and unit is dry before making any electrical

connections

! WARNING

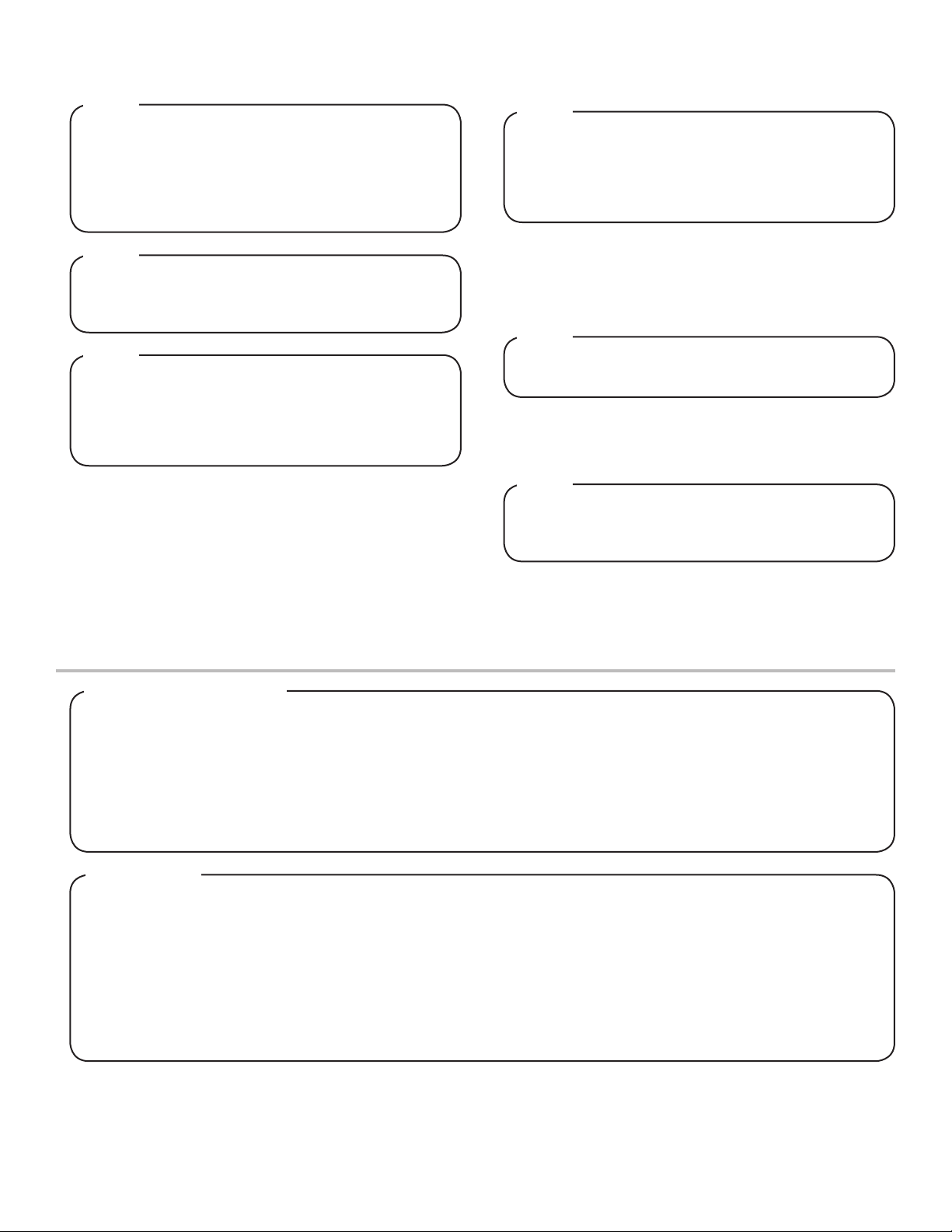

4. Route appropriate tubing from the syrup pump location to the

syrup inlets and connect tubing to inlet. Repeat for remaining

syrup lines

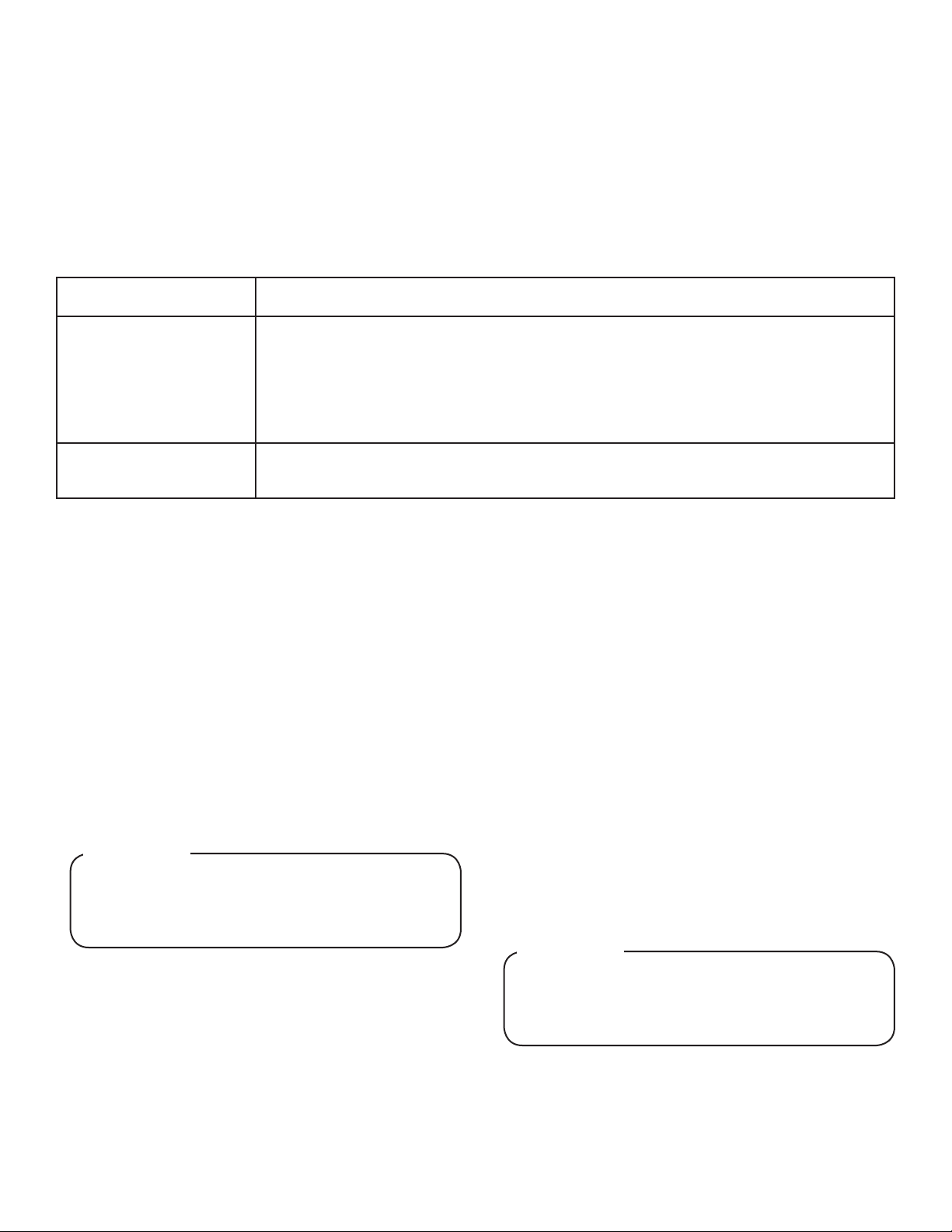

5. Route the power supply cord to a grounded electrical outlet

of the proper voltage and amperage rating.

Drain line must be insulated with a closed cell

insulation. Insulation must cover the entire length of

thedrainhose,includingttings.Thedrainshouldbe

installed in such a manner that water does not collect

in sags or other low points, as condensation will form.

! CAUTION

Pouring hot water down the drain may cause the Drain

Tube to collapse. Allow only luke warm or cold water to

enter the Drain Tube. Pouringcoee,tea,orother

similar substances down the drain may cause the Drain

Tube to become clogged.

! ATTENTION

2. Connect tubing to water source then ush water line to check

for leaks.

3. Route appropriate tubing from the remote chiller system

location to the carbonated water inlet on tower and connect

tubing to inlet.