3

INSTALLATION

Unpack the Dispenser

1. Cut package banding straps and remove.

2. Open the box and remove the parts tray.

3. Close the lid, then remove using the handle cutouts.

4. Remove accessory kit and loose parts.

Inspect unit for concealed damage. If evident, notify

delivering carrier and le a claim against the same.

NOTE

If unit is to be transported, it is advisable to leave the

unit secured to the plywood shipping base.

NOTE

5. Remove plywood shipping base from unit by moving unit so

that one side is o the counter top or table allowing access

to screws on the bottom of the plywood shipping base.

6. If leg kit has been provided, assemble legs by tilting unit.

DO NOT LAY UNIT ON ITS SIDE OR BACK

!ATTENTION

Selecting/Preparing Counter Location

The dispenser should only be installed in a location

where it can be overseen by trained personnel

NOTE

1. Select a location that is in close proximity to a properly

grounded electrical outlet, within ve (5) feet (1.5 m) of

a drain, and a water supply that meets the requirements

shown in the Specications section found on page 2.

4. Cut the necessary holes in counter for mounting in the

designated dispenser location.

In order to facilitate proper dispenser drainage, ensure

that the dispenser is level, front to back and side to

side. Place a level on the top of the rear edge of the

dispenser. The bubble must settle between the level

lines. Repeat this procedure for the remaining three

sides. Level unit if necessary. For optimum perfor-

mance place the unit at a 0° tilt. The maximum tilt is 5°.

Leveling the Dispenser

Dispenser Installation

1. The dispenser is designed to be installed either

permanently to counter or placed on a counter using the legs

(included in the Lancer kit, PN 82-1704).

2. When the dispenser is to be permanently bolted to the

counter top, the dispenser base must be sealed to the

counter top with a bead of clear silicone caulk or sealant

which provides a smooth and easily cleanable bond to the

counter.

3. Once the dispenser is installed to the counter or placed on

the counter using legs provided, remove the cup rest, splash

plate, and valve shroud.

4. Connect drain tube to the drain tting located on the bottom

of the drip tray and secure drain tube with clamp.

5. Route the drain line to designated oor drain.

6. Remove the bonnet screw from the top of the unit and lift the

bonnet to remove from the dispenser.

7. Route appropriate tubing from the syrup pump location to the

syrup inlets located behind the splash plate. Connect tubing

to inlets using the oetiker pliers and ttings. Repeat for all

syrup connections.

The installation, and relocation if necessary, must

be carried out by qualied personnel with up-to-date

knowledge and practical experience, in accordance with

current regulations.

NOTE

NSF listed units must be sealed to the counter or use

legs provided.

NOTE

Never energize the machine if there is any trace of

damage. Contact Lancer Customer Service for

assistance.

H WARNING

Keep ventilation openings, in the appliance enclosure

or in the built-in structure clear of obstruction. Failure

to maintain specied clearance will cause the compres-

sor to overheat and will result in compressor failure.

H WARNING

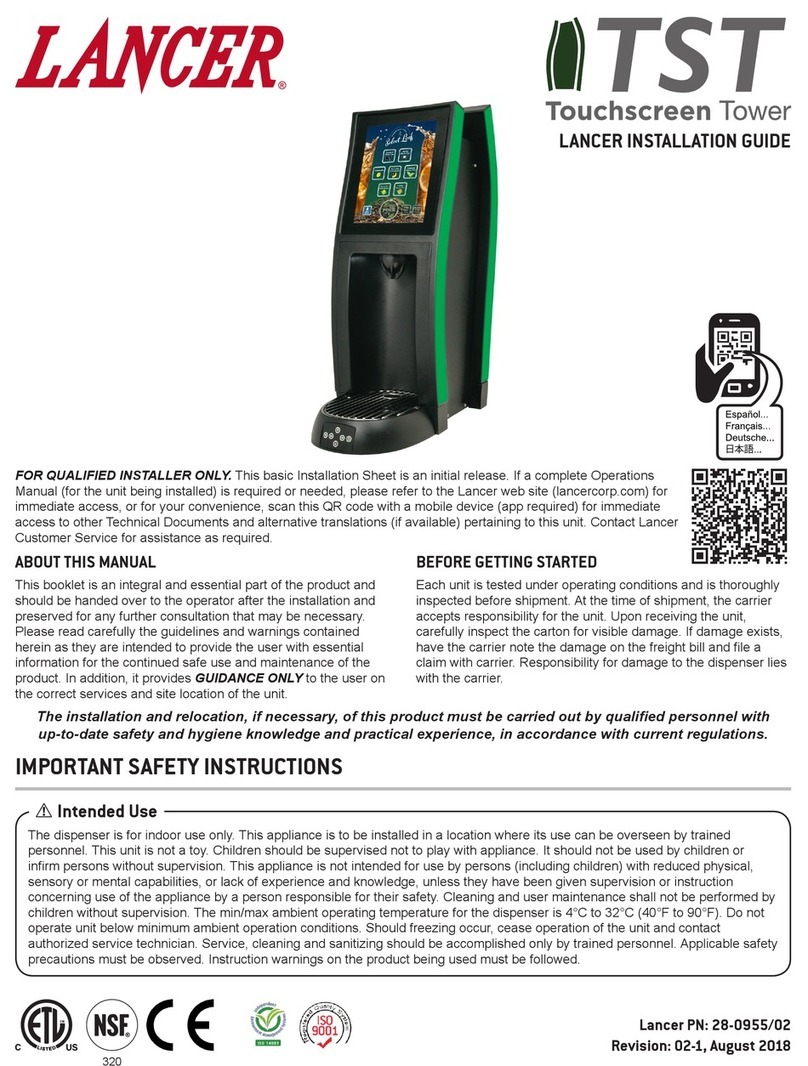

A

B

C

A. Oetiker Pliers

B. Fitting

C. Tubing

D. Syrup/Water/CO2

Inlet

D

When positioning the appliance, ensure the supply

cord is not trapped or damaged.

H WARNING

2. Select a location for the syrup pumps, CO2tank, syrup

containers, and water lter (recommended).

3. Condenser air is drawn in from the front and side vents

located on the bonnet and discharged out the rear of the

bonnet. A minimum of eight (8) inches (203 mm) of clearance

must be maintained over the top of the unit and a minimum

of four (4) inches (101.6 mm) clearance behind the unit to

provide for proper air ow and circulation.