BEV85 Annual Operational Service

Work Instruction

www.lancerbeverage.com Page 4 of 4

Images are for illustration purposes only as product may vary. No 074 –1 November 2018

Replace cylinder head

assembly

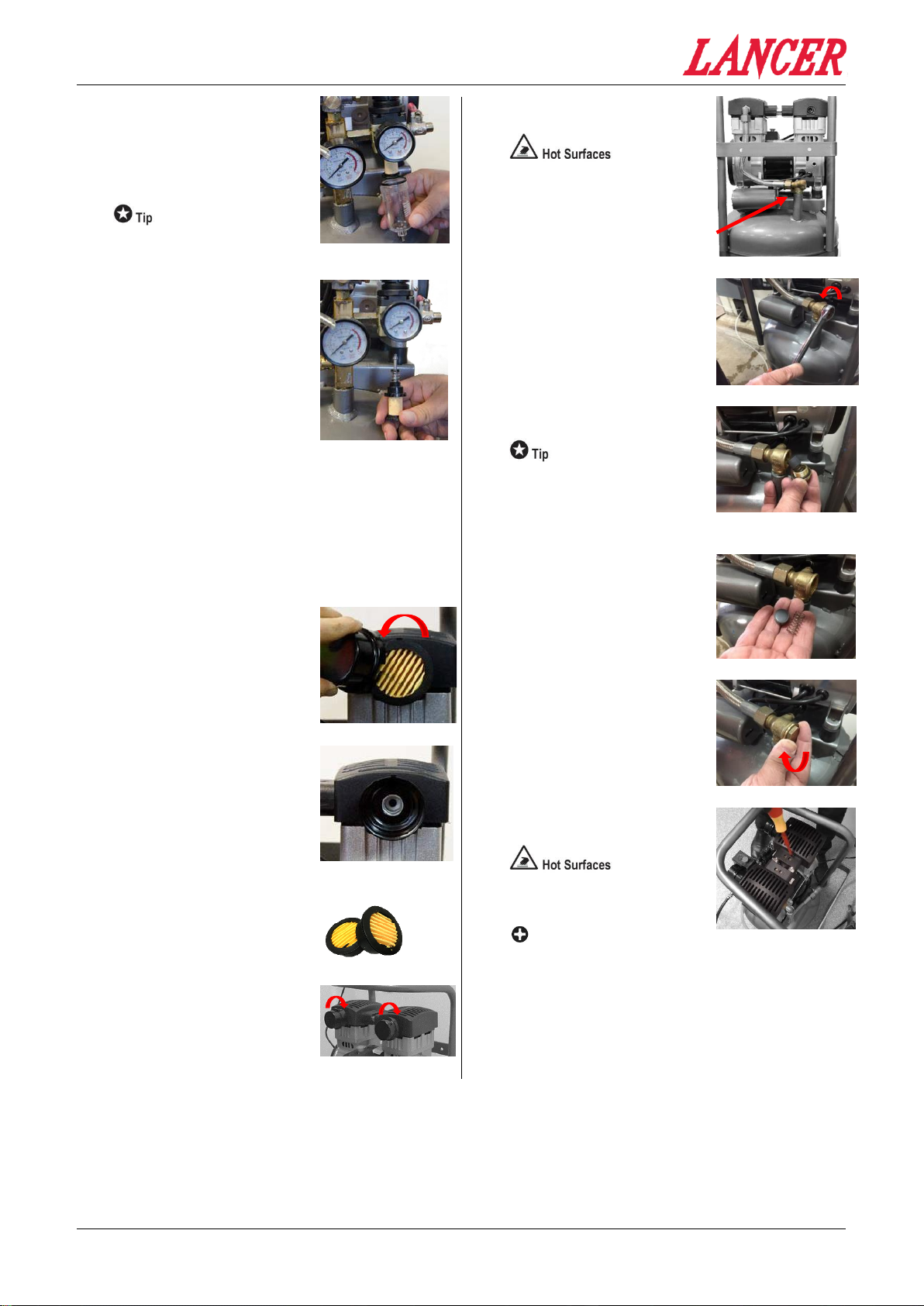

Tighten all 12 head bolts

Follow tensioning pattern

Hand tighten each bolt,

clockwise, extra leverage is

not required.

Each bolt has a spring

washer, fitted to assist with

securing the fixing.

Aluminum threads strip easily.

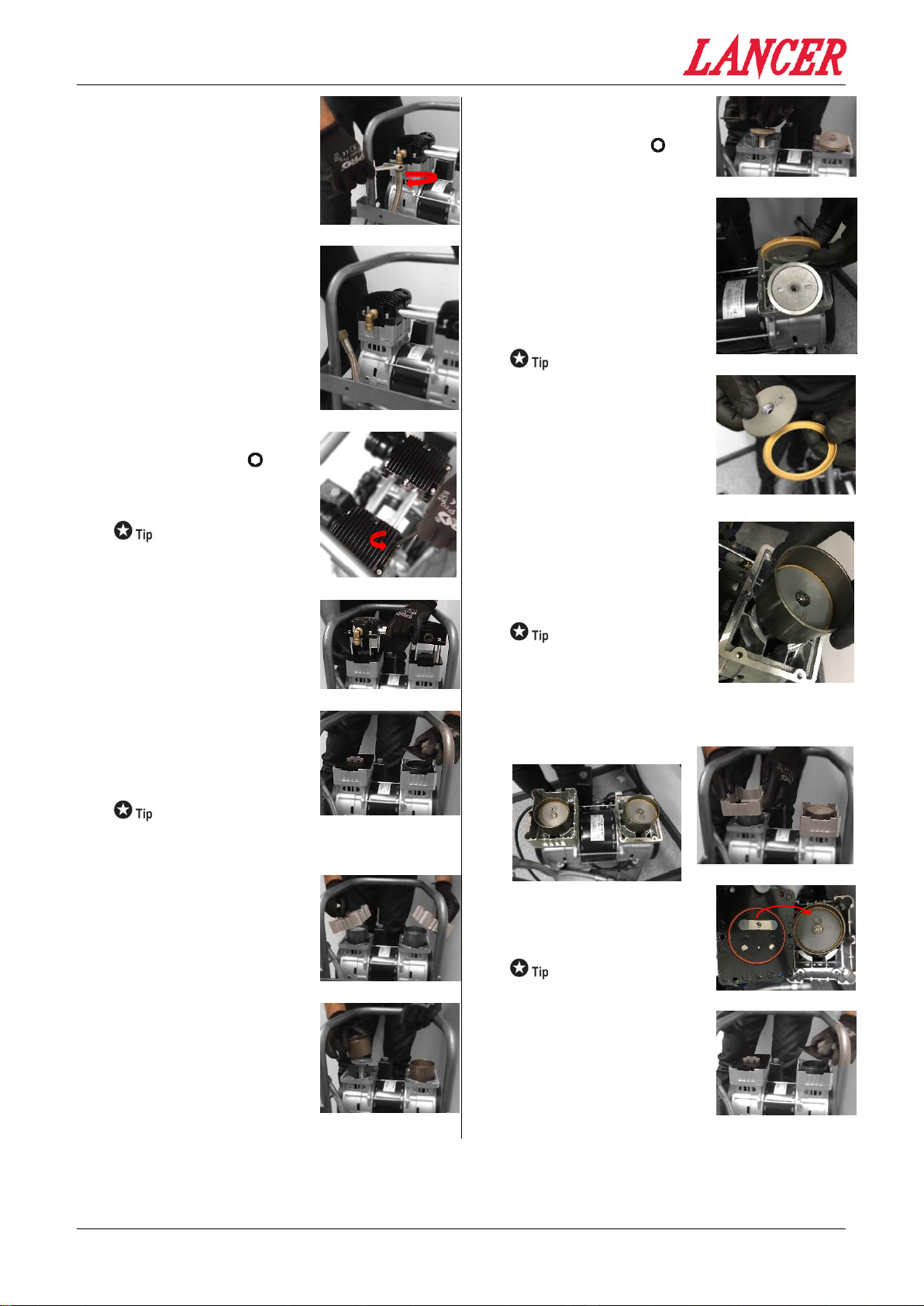

Connect High Pressure

hose

Using a Spanner, Turn anti-

Clockwise to tighten hose

fitting.

Replace heat covers

PH2 Phillips heads

2 x heat covers

Replace heat covers, secure

each with 2 fixing screws.

Re-connect and energise

the electrical supply to the

air compressor

Plug electrical lead into socket

outlet and lift red button on

pressure switch to turn on the

air compressor.

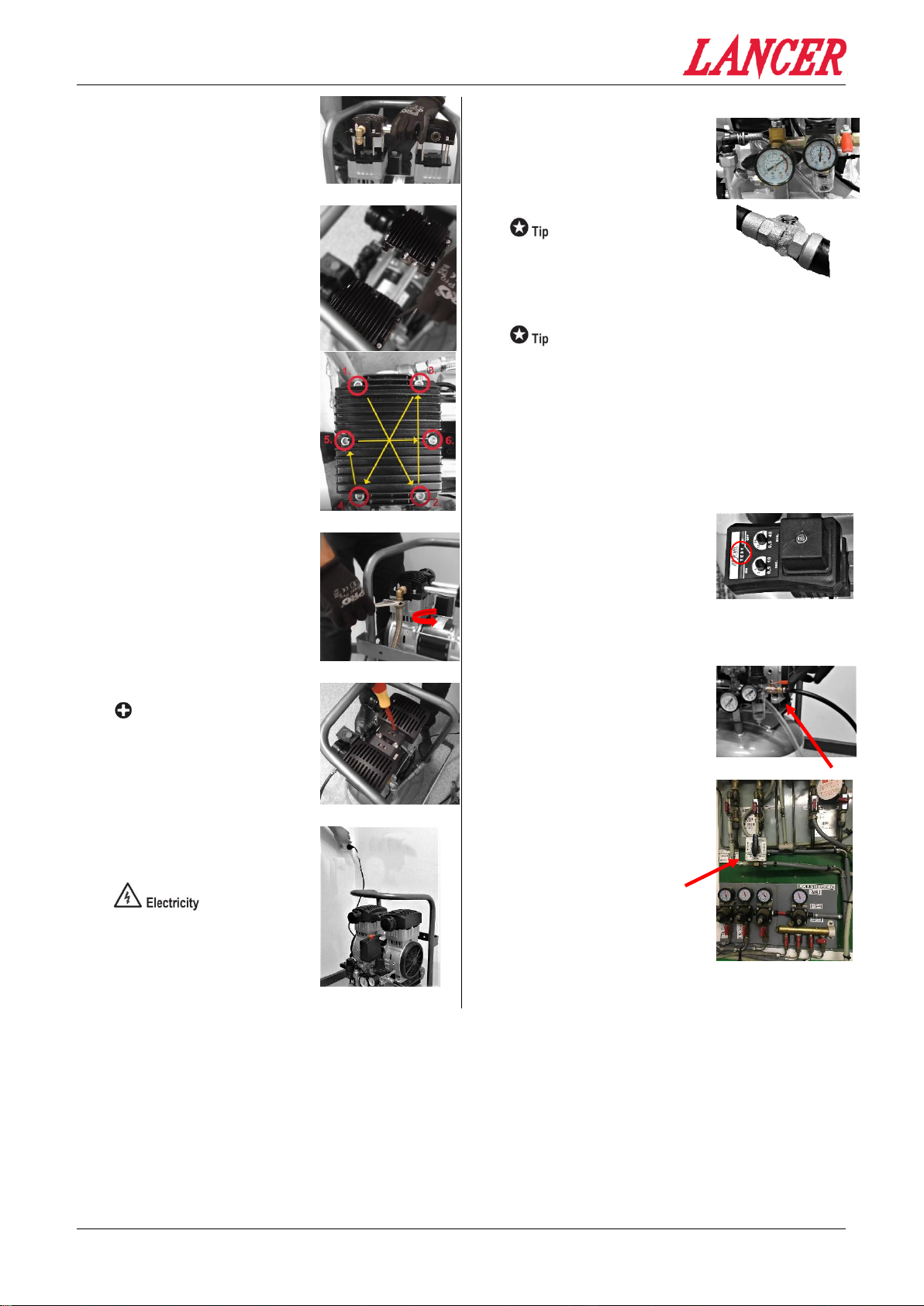

Check for air leaks

Monitor the tank pressure

gauge, listen for leaking air

(hissing) and/or use soapy

water to inspect air fittings,

pipe joints & connections.

Compressor will run for about

1 minute 30 second before

cycling off.

Check the NRV Operation

When the compressor

reaches its cut-out pressure

there should be a shot of air

from underneath the pressure

switch. If this shot of air is not

evident or the air continually

leaks replace the Non-Return

Valve Seal & Spring.

Test auto-drain

Press the “TEST” button on

the Auto Drain which should

release a burst of air and then

stop.

If this does not work have the

compressor checked by an

approved service agent.

Re-connect air supply

Turn the supply air tap on, ¼

turn. Handle will be in line with

the hose.

This is the red handle.

Change Over to

Compressed Air supply

Switch main Beverage Control

Panel over to Compressed air

supply from CO2 supply.