LANCO

Dr. Lange GmbH & Co. KG

Sure Wisch 6

D-30625 Hannover

Telefon:

Telefax:

E-Mail:

Internet:

+49 (0) 511 9 56 87-0

+49 (0) 511 9 56 87-40

www.lanco.eu

Page 4/5

Manual – ARZ 10, ARZ 204, ARZ 20 – ARZ 60

Erstellt: cschneider Freigabe: Abé Version 02

Datum: 20.02.2012 Datum: 20.02.2012

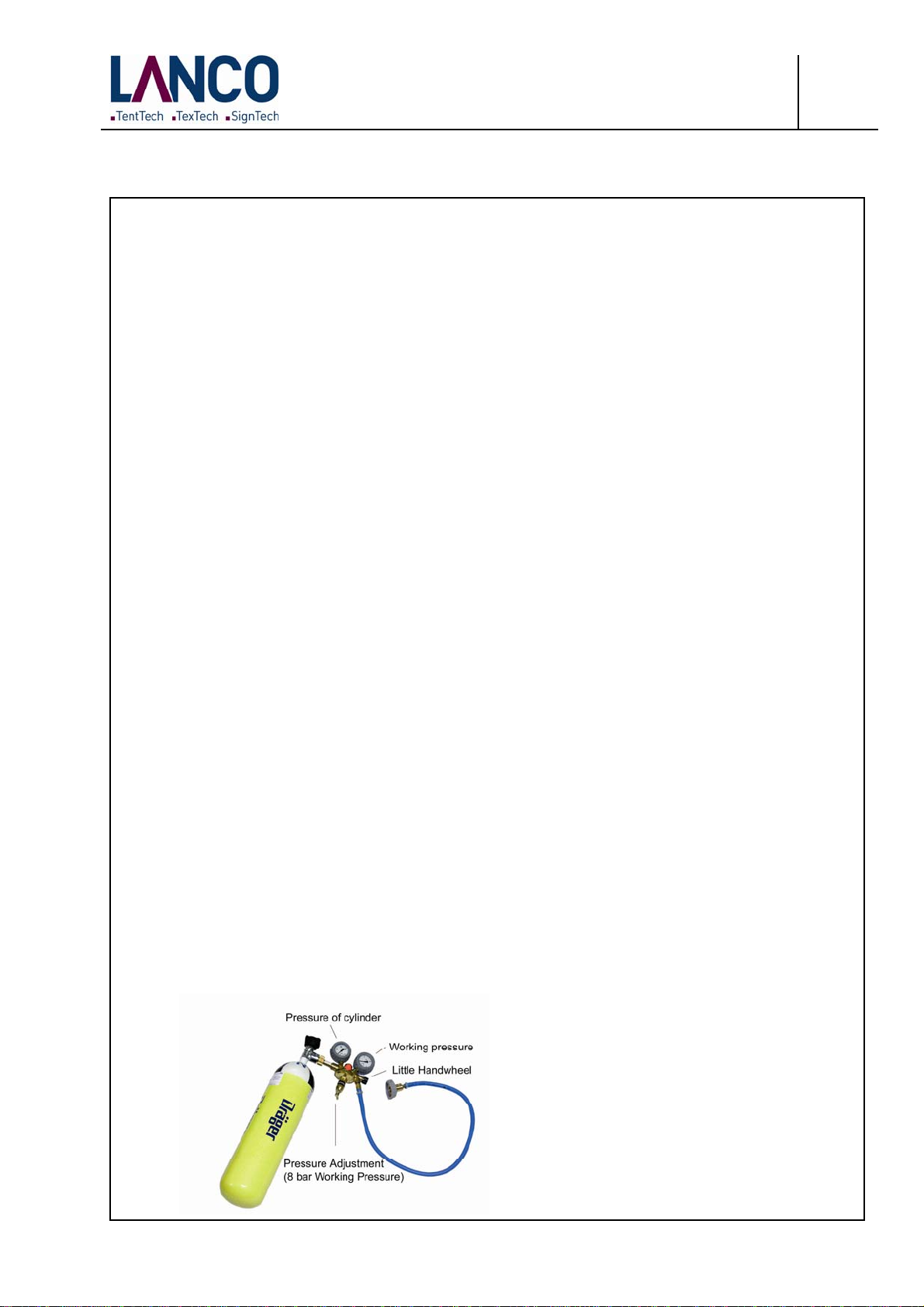

d) The end of the hose has to be connected to the adapter which is fixed at the in- and deflation

valve of the tent.

Caution: The hose will be under pressure. If it is not properly fixed, it might slip off during

the inflation process and cause injuries.

e) Close pressure reducer valve (little handwheel).

f) Open bottle valve totally. The left pressure gauge shows the bottle pressure - the right pressure

gauge shows the working pressure of the pressure reducer. The working pressure has to be

8 bar. If needed adjust the working pressure to this value by turning the adjustment screw at the

bottom.

g) Now open the pressure reducer valve (little handwheel) to fill the tube system.

h) If you use more than one cylinder, check all the working pressures before you open the pressure

reducer valves one after the other.

i) As soon as the pressure relief valve of the tent opens or the cylinders are almost empty, close the

cylinder valve in order to prevent the total emptying of the bottle.

j) Take off the pressure hoses and replace the pressure reducer at the cylinder with a dummy plug.

3.3 Final Work to Do

a) Fix tent with T-pegs 30cm to the ground.

b) Fasten storm cords with T-pegs and tighten them.

3.4 Important Information

a) Avoid punctual weight and sharp things on the groundsheet.

b) When there are first signs of low pressure of the tube system start refilling according to inflation

process 3.2.

c) Check storm cords regularly and tighten again if needed.

d) When you assume that a tube is leaky, lather the tube in order to locate the leaky spot. Repair

according to No. 5.

e) Snow loads have to be removed immediately.

4. Deflation and Packing of the Tent

4.1 Deflation

a) Take out everything of the tent.

b) Take especially care of little stones, loose chippings and peaky objects.

c) Press down and turn anticlockwise in- and deflations valves to open them. The air needs about 5

to 10 minutes to exhaust.

d) Exhaust the air properly with the hand-pump or electrical blower.

4.2 Folding and Packing

a) Spread out tent roof even and flat.

b) Loosen all fixtures. Lay cords on the tent.

c) Collect all pegs, clean and pack them.

d) Fold tent and clean it as possible.

e) Roll in tent and squeeze out the remaining air with your knees.

f) Close valves and put on protective caps.

g) Place the packing bag under the end of the folded tent and roll it into the bag.

h) Pack all accessories.