Alle Angaben verstehen sich als unverbindliche Richtwerte! Für nicht schriftlich bestätigte Datenauswahl übernehmen wir keine Haftung. Druckangaben beziehen sich, soweit nicht anders angegeben, auf Flüssigkeiten der Gruppe II bei +20°C.

1

Dokumentation VORTEX-Rohre

1. Inhalt

1. Inhalt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. Artikelnummern und Daten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. Sicherheitshinweis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. Funtionsweise und Einstellung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

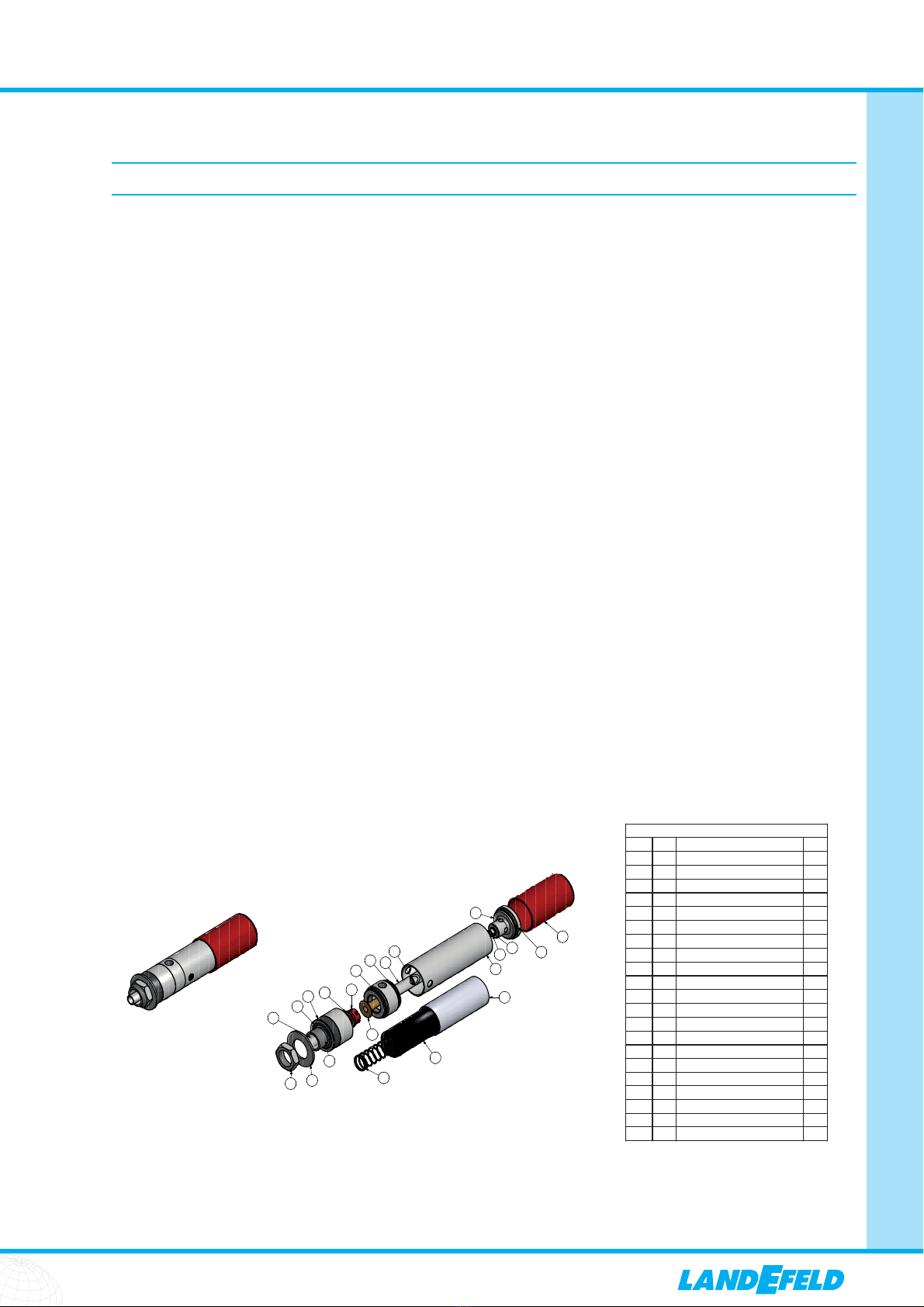

5. Austausch des VORTEX-Generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. Leistungsdaten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. Teileliste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

8. Abmessungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

8.1. VORTEX 14 B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

8.2. VORTEX 14 KB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

8.3. VORTEX 14 CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

9. Bedienungsanleitung VORTEX 14 KP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

10. Bedienungsanleitung VORTEX 14 CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Artikelnummern und Daten

3. Sicherheitshinweis

Achtung: Das VORTEX-Rohr erzeugt sowohl kalte als auch heiße Luft. Teile des Rohres werden im

Betrieb heiß/kalt und sollten nicht berührt werden.

Luft- Kaltluft- Bau-

Typ eintritt austritt länge Rohr-Ø Lieferumfang

VORTEX 14 B Rp 1/4“ IG G 1/4“ AG 210 45 VORTEX-Rohr mit rotem Generator

VORTEX 14 Rp 1/4“ IG G 1/2“ IG 285 45 VORTEX-Rohr mit Schalldämpfer (für Kaltluft-

seite), 8 Stk. VORTEX-Generatoren (gelb, grün,

rot, weiß, blau, grau, beige), Gelenkschlauch

für Kaltluft

VORTEX 14 KP Rp 1/4“ IG G 1/2“ IG 285 45 VORTEX-Rohr mit Schalldämpfer (für Kalt- und

Warmluftseite), 4 Stk. VORTEX-Generatoren

(gelb, rot, blau, braun), Gelenkschlauch für

Kaltluft, Magnetfuß

VORTEX 14 CC ** Rp 1/4“ IG Gehäuse- 200 45 VORTEX-Rohr zur Schaltschrankkühlung (max.

befestigung 1800x1800x600), Thermostatsteuerung, 4 Stk.

in 3/4“-Loch, VORTEX-Generatoren (gelb, rot, blau, braun),

Luftverteilung Abluftventil in VORTEX-Rohr integriert, Schlauch

durch Schlauch zur Luftverteilung, ausgeführt nach IP 56

** bitte gewünschte Spannung angeben

VORTEX-Rohre - druckluftbetriebene Kältegeneratoren

Funktion: Einströmende Druckluft wird durch das VORTEX-Rohr in einen Warmluft- und einen Kaltluftstrom aufgeteilt.

Die warme Luft tritt auf der einen, die kalte Luft auf der anderen Seite des Rohres aus. Durch ein Regulierventil lässt sich

die Temperaturdifferenz zwischen eintretender Druckluft und austretender Kaltluft einstellen. Bei sinkender

Austrittstemperatur verringert sich gleichzeitig die austretende Kaltluftmenge. Es lassen sich Temperaturen von -40°C auf

der Kaltluft- und bis zu +110°C auf der Heißluftseite erzeugen. Bei konstanter Lufteintrittstemperatur und Druck kann

die Austrittstemperatur mit einer Toleranz von +/- 0,6 K eingestellt werden.

Werkstoffe: Gehäuse: Edelstahl AISI 303, VORTEX-Generator: Kunststoff

Temperaturbereich: -20°C bis max. +120°C

Betriebsdruck: 1 - 8 bar, optimal: 5 bar (gefilterte, ungeölte Druckluft)

Anwendungsbeispiele: Ÿgenaue Temperaturregelung

Ÿgenaue Anpassung des VORTEX-Rohres an jede Anforderung durch mitgelieferte leicht

wechselbare VORTEX-Generatoren

ŸKühlung von Lötstellen, Heißkleber oder Klebstoffen

ŸKühlung beim Punktschweißen, vermeidet Verfärbungen und Verformungen

ŸKühlung von z. B. flüssiger Schokolade in der Lebensmittelverarbeitung

ŸKühlung von Kaltform- und Ultraschallwerkzeugen

ŸKühlung bei spanabhebender Bearbeitung ohne Kühlmittel (z. B. für Kunststoffe)

ŸKühlung von Nadeln in Nähmaschinen

ŸKühlung von Schneidwerkzeugen

ŸThermo-Prüfung elektronischer Komponenten

ŸSchrumpfpassungen

orteile: Ÿgeringe Anschaffungs- und Betriebskosten

Ÿwartungsfrei

Ÿkeine beweglichen Bauteile - kein Verschleiß

ü

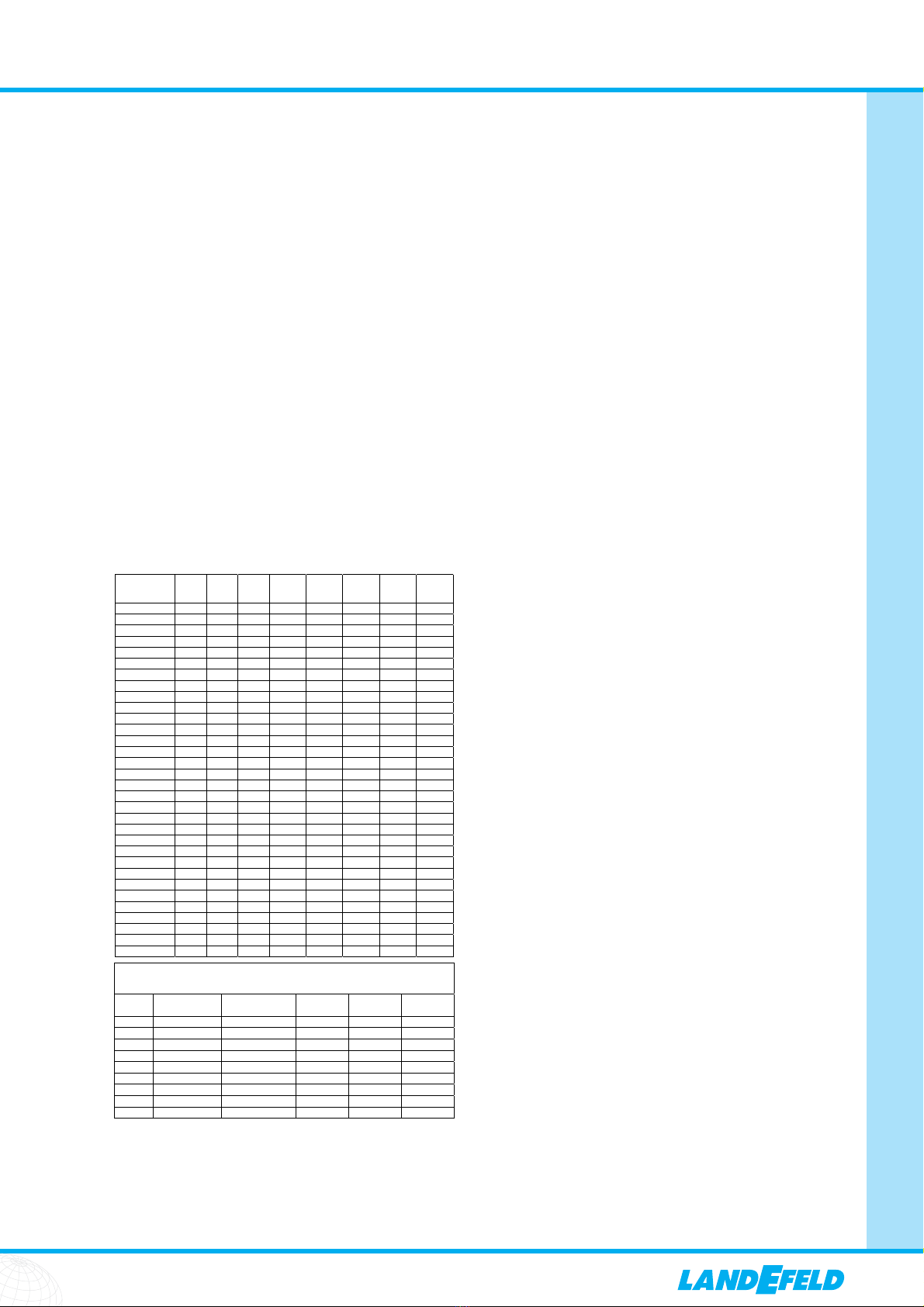

Farbe gelb grün rot*** weiß blau grau beige braun

Temperatur* -31C° -33C° -30C° -34C° -26C° -30C° -24C° -29C°

Kälteleistung* (kcal/h) 130 130 230 230 380 380 630 630

Luftverbrauch* (l/min) 280 280 420 420 700 700 990 990

* Lufteintritt bei 5,5 bar und 20°C, Regelungsschraube 2,5 Umdrehungen geöffnet (70% des Luftstrahls entweicht als Kaltluft)

*** als Standard in allen VORTEX-Rohren eingebaut

VORTEX-Generatoren

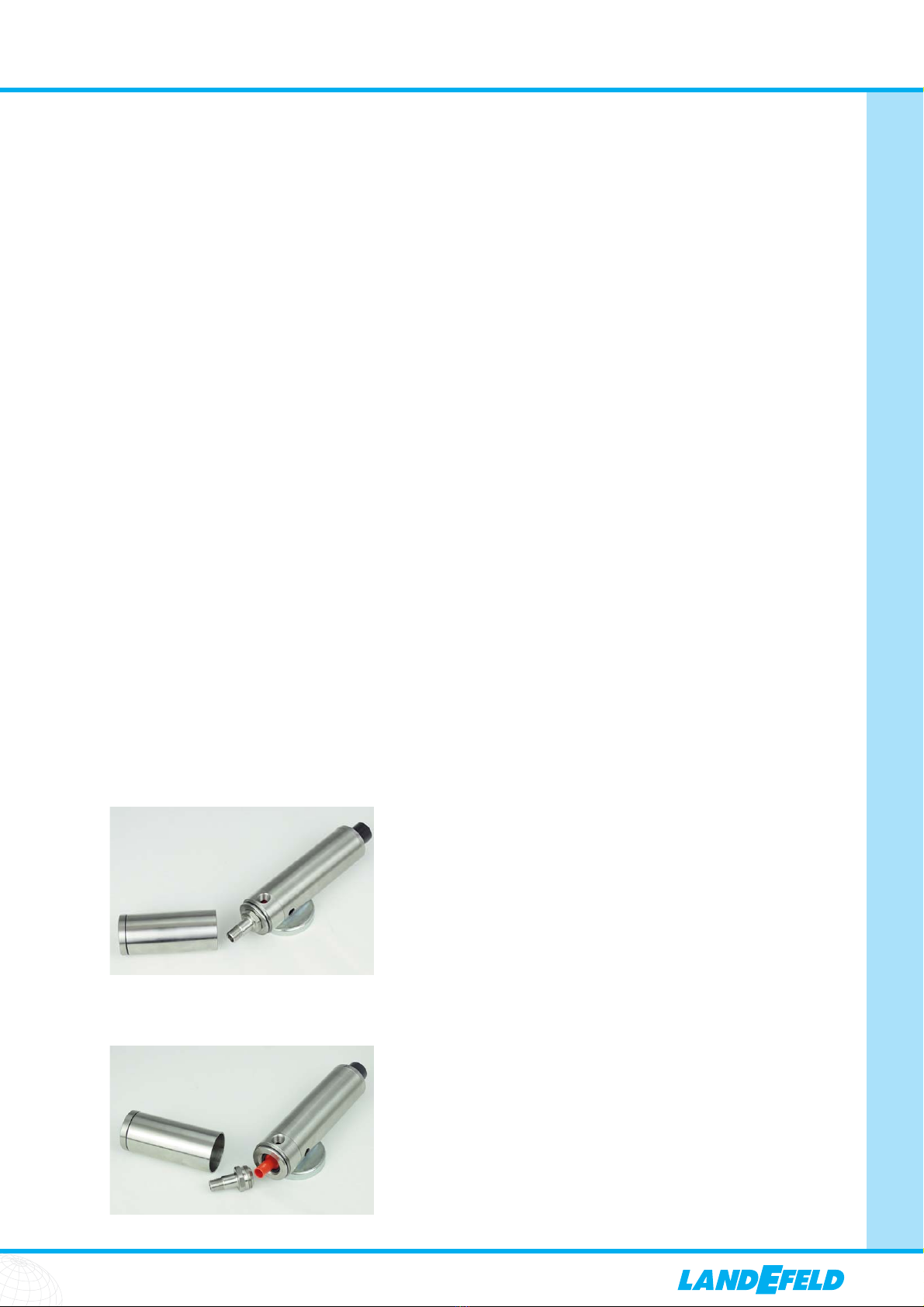

Typ VORTEX 14 B

Typ VORTEX 14 KP

Typ VORTEX 14 CC

Kälteerzeugung mit Druckluft!

Ÿfür den Betrieb wird nur Druckluft benötigt,

keine Elektrizität

Ÿkeine Rückstände auf dem gekühltem Gut

durch Kühlmittel oder Kältespray

Typ VORTEX 14