Lang 224ZT User manual

Other Lang Griddle manuals

Lang

Lang CLG-48A-S Operating instructions

Lang

Lang 324T User manual

Lang

Lang 224Z Owner's manual

Lang

Lang 224S User manual

Lang

Lang CLGPB-48-S Operating instructions

Lang

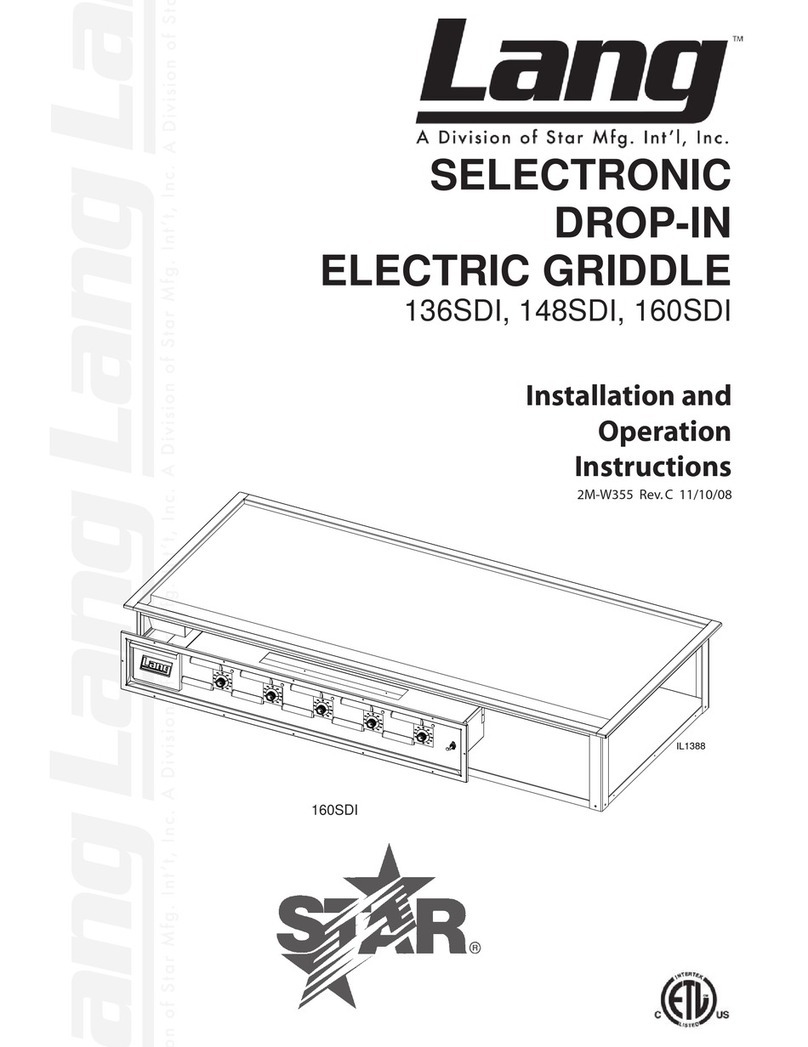

Lang 136SDI User manual

Lang

Lang 224TH User manual

Lang

Lang CLGPB-36-S Operating instructions

Lang

Lang 124T User manual

Lang

Lang CLG-36-U Operating instructions

Lang

Lang 136S-M Manual

Lang

Lang 136SB-WB Manual

Lang

Lang CLG-36-S Operating instructions

Lang

Lang 148S-SC Owner's manual

Lang

Lang 124TH User manual

Lang

Lang PBE12 Owner's manual

Lang

Lang 124S User manual

Lang

Lang GGB-24 Owner's manual

Lang

Lang 424T User manual

Lang

Lang XL-24 Electric Clamshell Operating instructions

Popular Griddle manuals by other brands

Dyna-Glo

Dyna-Glo DGL260SNP manual

Char-Broil

Char-Broil 19952085 Product guide

APW Wyott

APW Wyott HMG-2424 Installation and operating instructions

Pit Boss

Pit Boss Ultimate Griddle PB2BGD2 Assembly guide

Airxcel

Airxcel Suburban Elite SOP-1005A Operation guide

Keating Of Chicago

Keating Of Chicago MIRACLEAN PRE-2000 manual

Nexgrill

Nexgrill 720-0786A owner's guide

Outwell

Outwell FH-3047C instruction manual

Rankam

Rankam Member's Mark GR2298901-MM-02 Assembly & operating instructions

Black Stone

Black Stone 1972 owner's manual

Star

Star Ultra Max 760TA Installation and operation instructions

NuWave

NuWave Precision Cast Iron Griddle User information