1General information .....................................................................................................3

2Safety information........................................................................................................3

3Product description......................................................................................................4

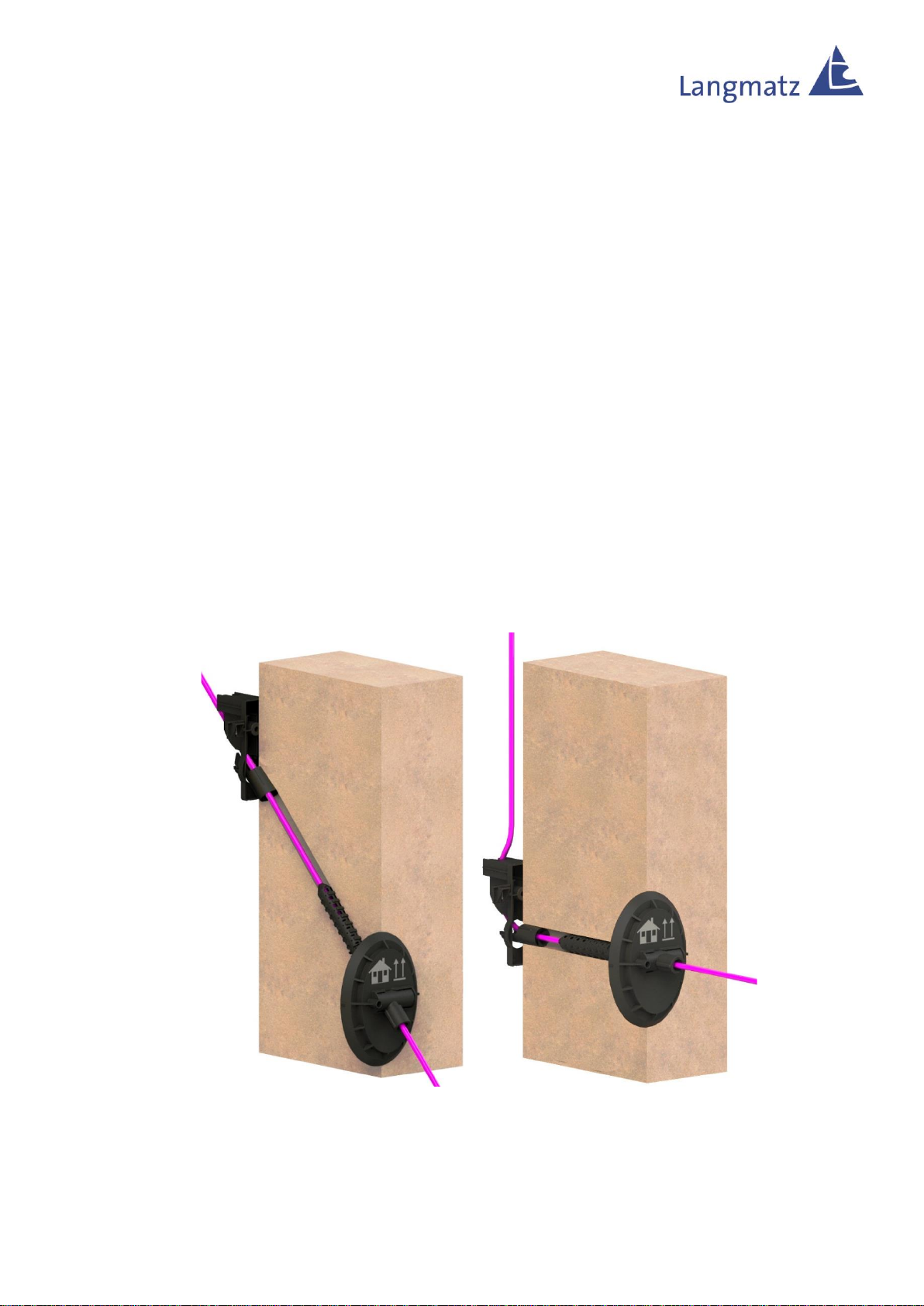

3.1 Installation options.................................................................................................4

3.2 Dimensions ............................................................................................................4

4Package includes.........................................................................................................5

5Required tools..............................................................................................................5

6Installation....................................................................................................................6

6.1 Drill hole.................................................................................................................6

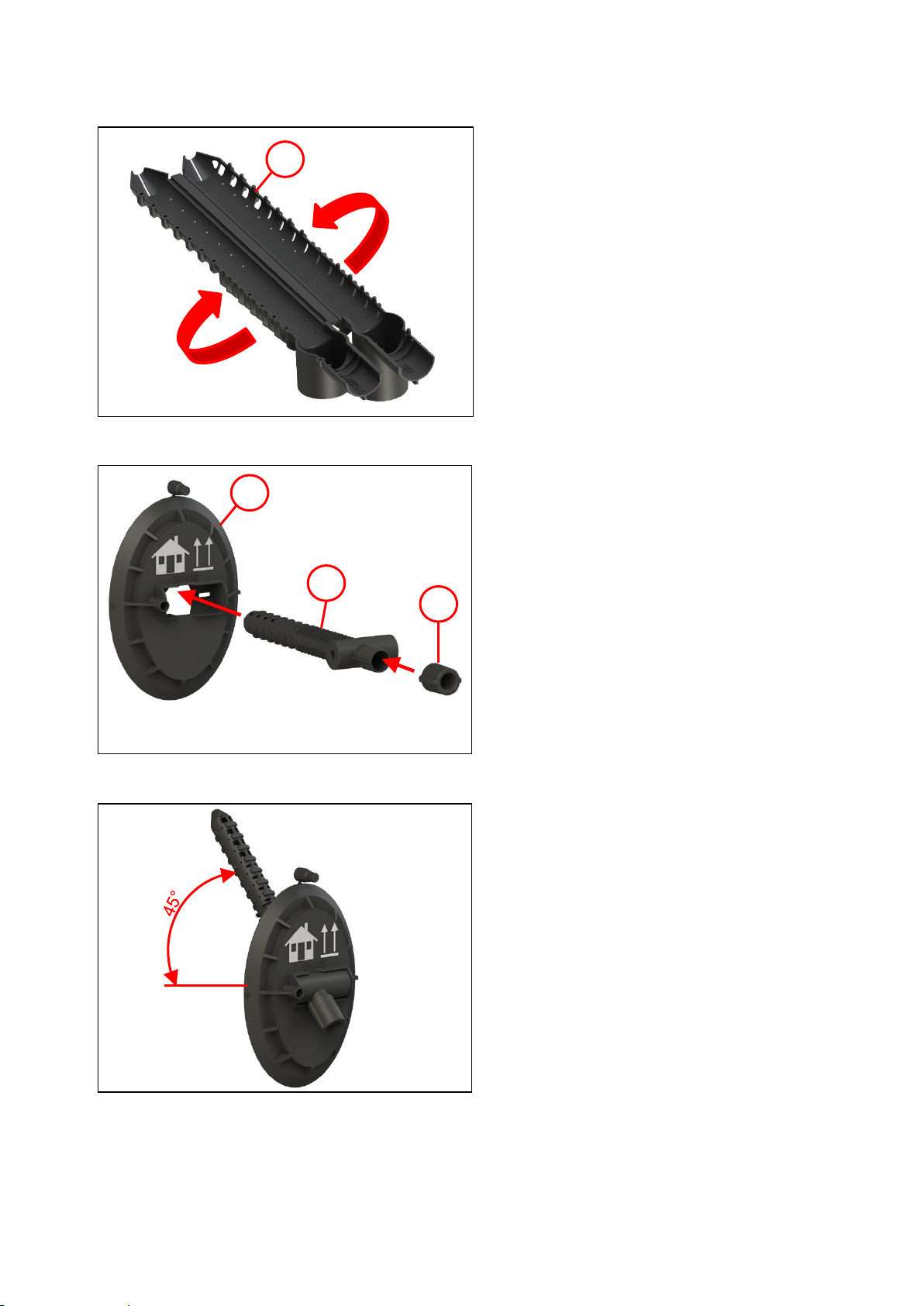

6.2 Preparing the wall duct..........................................................................................7

6.3 Preparing the media cable ....................................................................................9

6.4 Inserting the wall duct..........................................................................................10

6.5 Inserting the media cable ....................................................................................12

6.6 Injecting the sealing foam....................................................................................13

6.7 Continuing the media cable.................................................................................14

6.8 Cover (optional) ...................................................................................................15

7Accessories................................................................................................................15

8Material defects..........................................................................................................16

9Quality management..................................................................................................16

10 Disclaimer/Warranty ..................................................................................................16

11 Disposal......................................................................................................................16

12 Safety information sheet for L100 sealing foam .......................................................16

13 Contact.......................................................................................................................17