Page 7

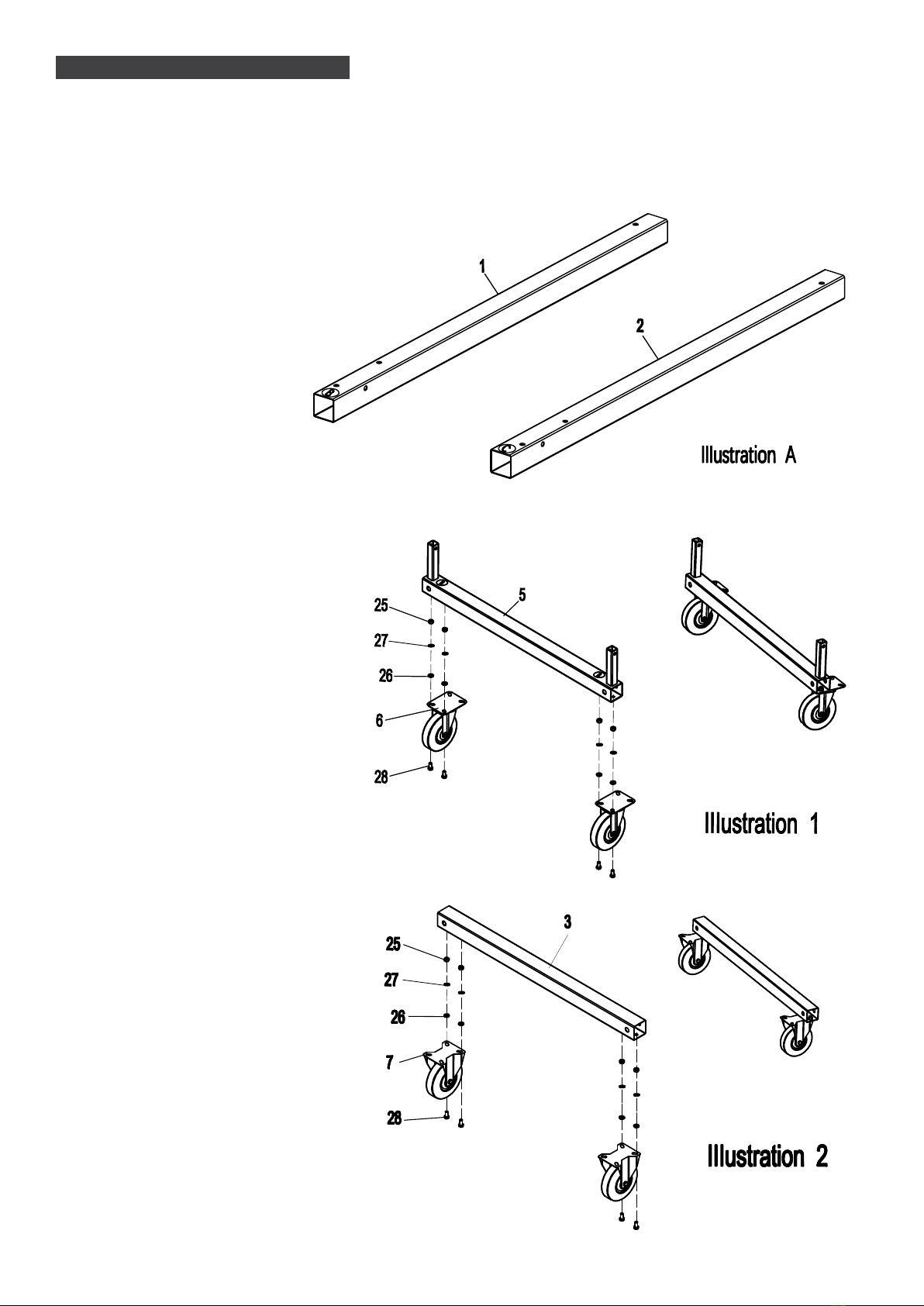

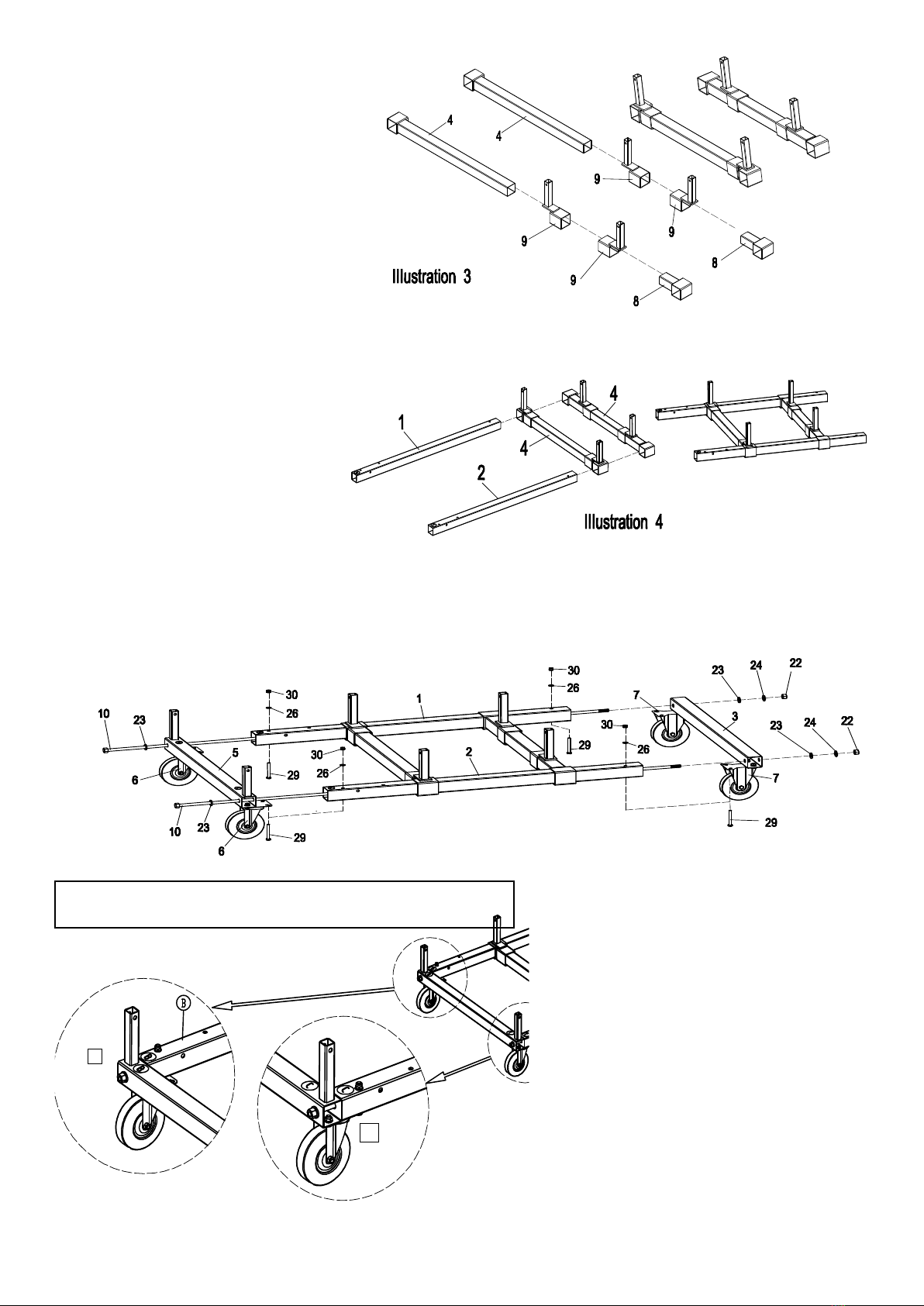

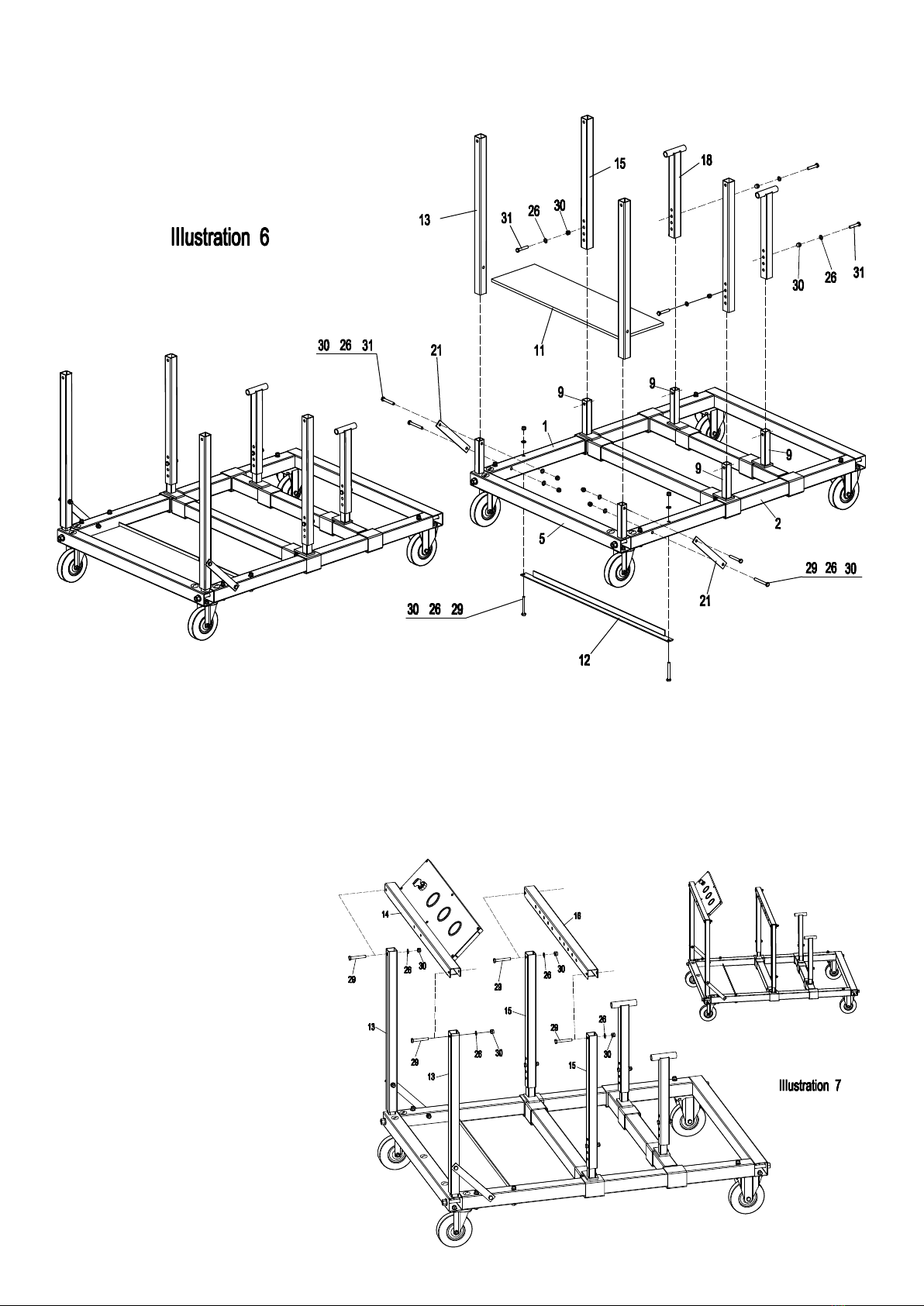

STEP 16 Place Engine Support

Strap (#17) onto Horizontal Bar

(#16). Attach with M10x65 bolt

(#32) , D10 Flat Washer (#33) ,

M10 Locknut (#34) .

See Illustration 8.

STEP 17 Slide Fuel Tank (#20)

into Fuel Tank Straps (#19).

Attach Fuel Tank Straps (#19) and

Dash Panel (#14) using M8x65

bolts (#29), D8 Flat Washer (#26)

and M8 Locknut .

See Illustration 8.

DIRECTIONS FOR USE

Use Precautions

Failure to heed these instructions may result in personal injury and/or property damage:

1. Study, understand, and follow all instructions before operating this device. Use as intended only.

2. Do not exceed rated capacity. Be aware of dynamic loading! Sudden load movement may briey create excess load causing

Product failure.

3. Use only on hard, level surfaces. Surfaces must be dry, clean and free from oil or grease.

4. Lock and chock wheels before applying a load.

5. Assure load is centered and secured to mounting attachments.

6. Wear ANSI-approved safety goggles and heavy-duty work gloves during use.

10. Inspect before every use, do not use if parts loose or damaged.

11. is product is not a toy. Do not allow children to play with or near this item.

12. Check and clean fuel tank before each use.

13. Secure the engine to the Testing Station as instructed.

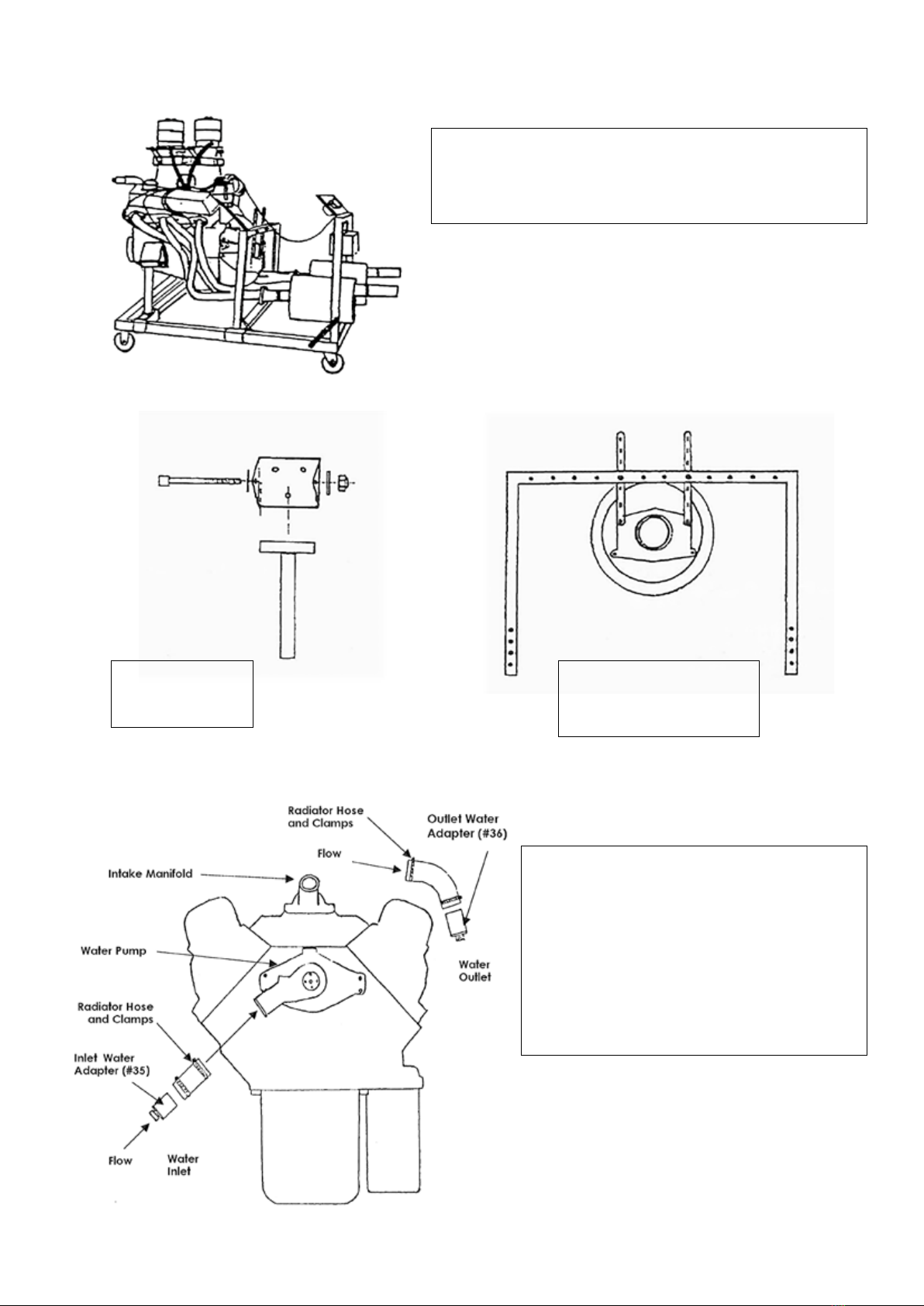

Mounting Engine

TO PREVENT SERIOUS INJURY:

Before attaching an engine to the stand, conrm that its weight does not exceed the Stand maximum capacity.

1. Determine the thread type and length of bolts (not included) needed to thread into the engine block.

2. Align the Engine Supports and Straps part# 17 and 18 with four mounting bolt locations on the engine.

3. Place the bolts (not included) through engine supports and straps and securely tighten them into the engine.

7. Slowly lower the hoist/engine crane (sold separately) until all the engine’s weight is held by the stand.

8. Safely release the engine from the hoist/engine crane.

Removing Engine

Secure the engine properly to the crane. Use the crane to support all of the engine’s weight directly overhead, once the

engine is properly supported by the crane, remove the bolts securing the Engine Supports and Straps Part# 18/17 to

the engine.

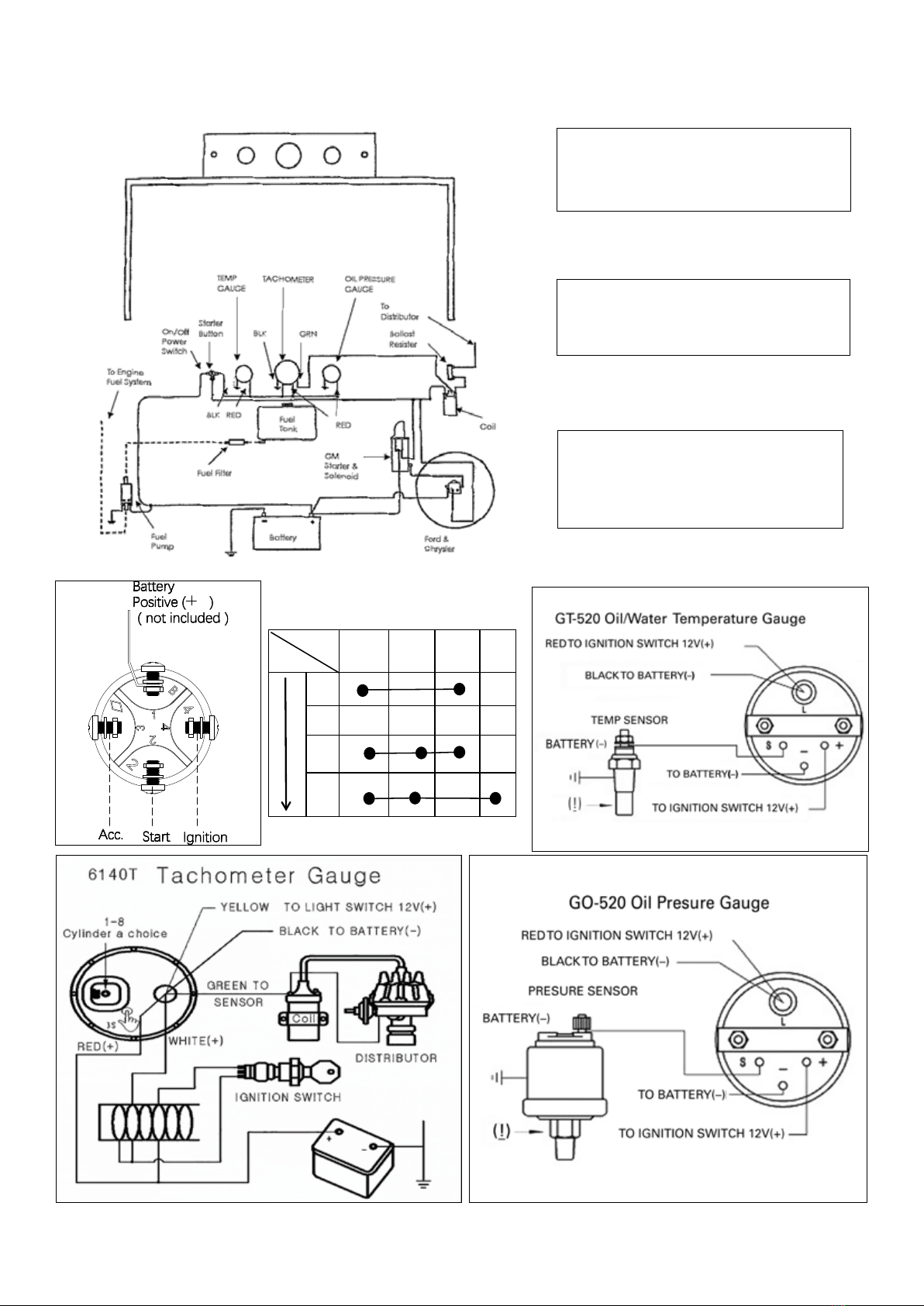

Helpful using tips refer to Figure 1, 2, 3.

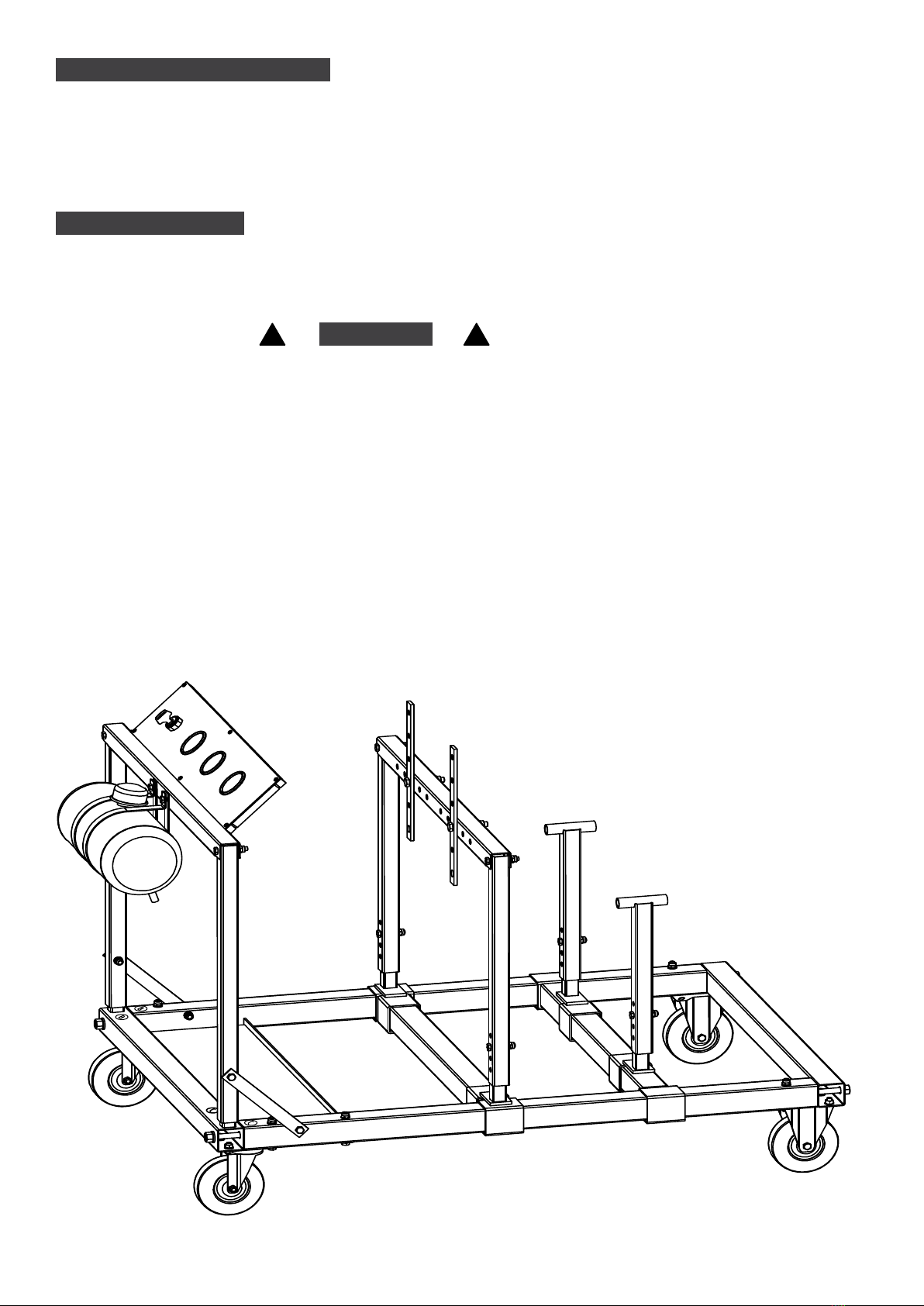

ASSEMBLED