Larson Electronics, LLC Phone: (800) 369-6671 Fax: (903) 498-3364 www.larsonelectronics.com 3of 13

IND-MD-TF-MGF-HH-R1

Product introduction

Thank you for your purchase of the Larson Electronics IND-MD-TF-MGF-HH-R1. It uses modern rocket technology,

with maintenance free pulse jet engine, without any rotating parts in the whole macine and has no need for a lubrication

system. The unit is a simple structure that has no wearing between components, low failure rate, long service life, easy

maintenance, less fuel consumption, and high working efficiency. It is an ideal, high-tech product tor pesticide spraying,

epidemic prevention and disinfection.

Performance characteristics

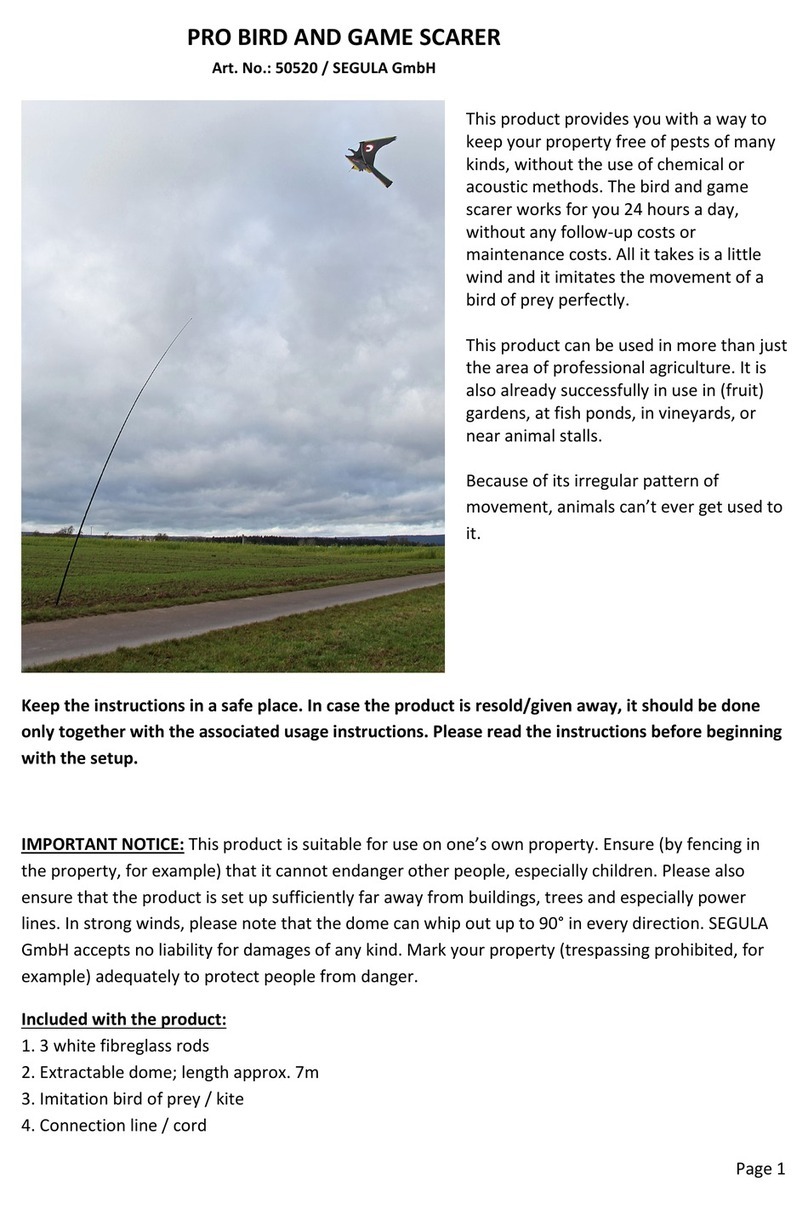

The smoke and mist spraying machine can be widely used for pesticide spraying for crops, economic forest,

cotton, greenhouse crops, sanitation and disinfection tor warehouse, wharf, army camp, city underground

waterways, farms, passenger cars, residential areas and city.

Characteristics:

1. High working efficiency, high killing rate, large spraying range, strong penetration and high safety factor;

2.

All around working without power off, stable performance and reliable;

3.

High- e

�

ficiency, pesticide-saving, low cost, good diffusibility and high adhesion;

4. Light weight and easy operation.

Characteristics when the machine is used in forestry and fruit trees:

(1) Drug-saving and less pollution: due to the small drug particle size and sufficient effect, the pesticide and

water usage is greatly reduced, which is good to be used in the water shortage area such as the mountains, hills,

plateau and etc.

(2) High insecticide efficiency: the special diffusion agent specially developed for smoke and mist sprayer by the

company has very good sterilizing effect. It has the advantage of strong adhesion, good anti-rain erosion,

weathering resistance, and large diffusion area etc. For example, it can used for the fruit rot, canker, pear scab,

anthracnose, aphids moth and whitefly, Botrytis cinerea and downy mildew, early blight, late blight, cotton bollworm,

fleahopper, and red spider etc, and is suitable for use with a variety of pesticides (foliar fertilizer, pesticides,

sterilization powder , etc.).

(3) To increase the temperature: in spring, when the crops is sprouting and flowering, the spraying smoke can

increase the surface temperature to prevent flower freezing and increase the yield and income .•

(4) Large spraying area and long distance: the flat spray area is large, and the spraying smoke can reach more

than 50 meters far. With small particle size and strong penetration, it is suitable for high stem and density

plants such as tea plantations, forest, fruit trees, the wheat in middle and later periods, cotton, maize, and rice etc ..

(5) The city hygiene and disease control, sanitation and transportation: suitable for hotels, parks, residential

property, city underpass, garbage dump, toilet, container, and warehouse etc to kill the "four pests". It is also

used for disinfection and sterilization of vehicles, such as station?,,docks, passenger ships, trains, automobiles,

aircraft, and etc.