Quick Read

WARNINGS!

TABLE OF

CONTENTS

INTRODUCTION

& WARNINGS

DESCRIPTION

& INSTALLATION

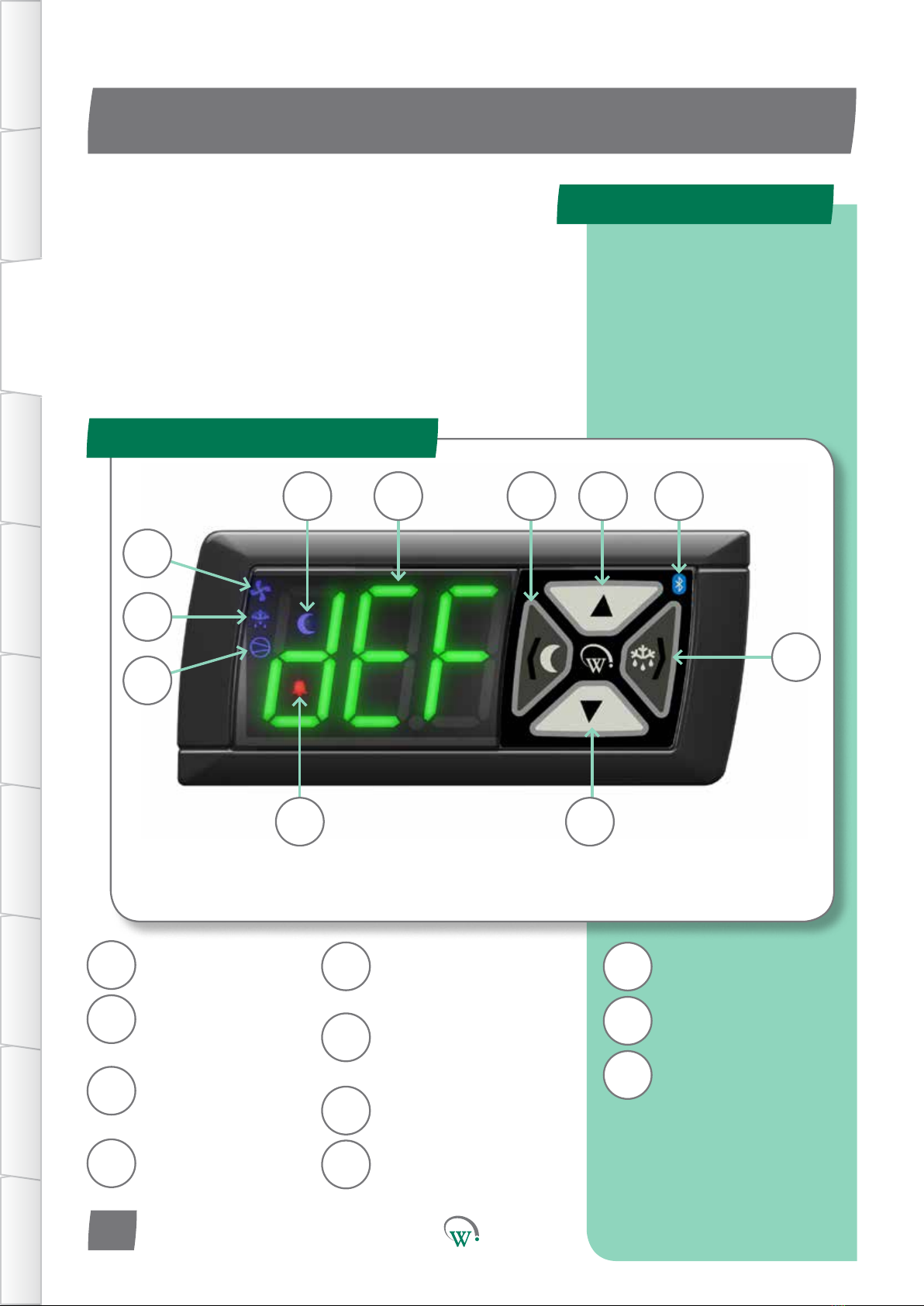

FRONT PANEL

USER INTERFACE

GRAPHICAL

USER INTERFACE PARAMETERS UPGRADING

FIRMWARE

FAULTS &

ALARMS

TECHNICAL

SPECIFICATION APPENDICES

Important Do’s and Dont’s:

Do not use water jets on the

rear of the unit. Warning!

Risk of electrocution. If

correctly installed, powerful

water jets may be applied

only to the front of the unit.

Do not drop the SCS

Connect.

There are no serviceable

parts inside the SCS

Connect. Do not open the

housing. Warning! Risk of

electrocution.

PD0006 v3.0 – 6 Dec 2017

4 4

Pleasereadthefollowingwarningstomaintainthesafefuncon

andconnuedperformanceofyourWellingtonDriveTechnologies

Limited SCS™ Connect controller:

Installaon;

InstallaonoftheSCS Connect controller other than in

accordancewiththe“Descripon&Install”seconofthis

manual will invalidate the warranty. The SCS™ Connect must

onlybeinstalledandconguredbytrainedandauthorizedsta.

Washdown;

The front of the unit may be exposed to water jets. Warning!

Therearoftheunitmustnotbeexposedtohighpressure

water jets or temporary submersion, as this will invalidate

thewarranty,andmaydamageelectroniccircuitsleadingto

prematurefailureorunsafeoperaon.Mounngoftheunit

mustbeinaccordancewithorientaonasspeciedinthe

“Descripon&Install”secon.Warning!Riskofelectrocuon.

Chemicals;

The SCS Connectcontroller’shousingismadeofpolycarbonate,

andshouldnotbeexposedtochemicalswhichaackthis

material,asthiswillinvalidatethewarrantyandmaydamage

thehousing,leadingtounsafeoperaon.Warning! Risk of

electrocuon

Temperature;

The SCS Connect controller must only be subjected to

temperaturesasspeciedinthe“TechnicalSpecicaons”

seconofthismanual.Exceedingtheseranges,eitherin

operaon,installaon,transportaon,orstorage,willinvalidate

thewarranty,andmaydamageelectroniccircuitsandhousing

components,leadingtoprematurefailure.

Vibraonandimpact;

The unit MUST be installed in such a way as to be protected

fromimpactinoperaon.Donothitordroptheunit.

Exposuretoimpacts,eitherinoperaon,installaon,

transportaon,orstorage,maydamageelectroniccircuits

andhousingcomponents,leadingtoprematurefailure,and

may cause the SCS Connect controller to become unsafe. Any

impactwhichcausesvisualdamagetothecontrollercasingwill

invalidate the warantee.

Noserviceableparts;

There are no serviceable parts inside the SCS Connect

controller.Donotopenthehousing,exceptfortherearcover,

asdescribedinthe“DescriponandInstallaon”seconof

thismanual.Openingoftheelectronicshousing,alterang

ormodifyingtheSCS Connect controller will invalidate the

warrantyandcancauseriskofelectrocuon.