LTI TruSense S300 Series Integration Manual 1st Edition

Page 5

Copyright © [2016] Laser Technology, Inc. All Rights Reserved. Unauthorized duplication, in whole or in part, is strictly prohibited.

Strongest Target ................................................................................................................................................................25

Last Target ........................................................................................................................................................................25

First, Second, Third Targets................................................................................................................................................25

Last 2 (Farthest and Second to Farthest) Targets...............................................................................................................25

First, Strongest, Last Targets..............................................................................................................................................25

First, Second, Third, Strongest, and Last Targets................................................................................................................25

$DT

Time Since Power ON ............................................................................................................................................26

$FD Reset Factory Default...........................................................................................................................................26

4-20 Current Loop Setting ............................................................................................................................................27

$GO

Start Distance Measurement .................................................................................................................................27

$HV

High Voltage Status .............................................................................................................................................28

$ID

InstrumentIdentification.......................................................................................................................................28

$IS $IS<CR><LF>.........................................................................................................................................................29

$MA Manual Start ........................................................................................................................................................29

$MU

Change

Measurement Unit...................................................................................................................................30

$OP

Output Precision...................................................................................................................................................30

$OZ

InstrumentTemperature ......................................................................................................................................30

$PD

Power Down and Restart Unit with New Baud Rate ..............................................................................................31

$PE Set Update Period ................................................................................................................................................31

$RD

Set Trip Distance ...................................................................................................................................................31

$SN

InstrumentSerial Number.....................................................................................................................................32

$ST

Stop DistanceMeasurement .................................................................................................................................32

$SU

Save User Settings ................................................................................................................................................32

$TG

RemoteTrigger .....................................................................................................................................................33

$UO

User Offset

............................................................................................................................................................34

$VO

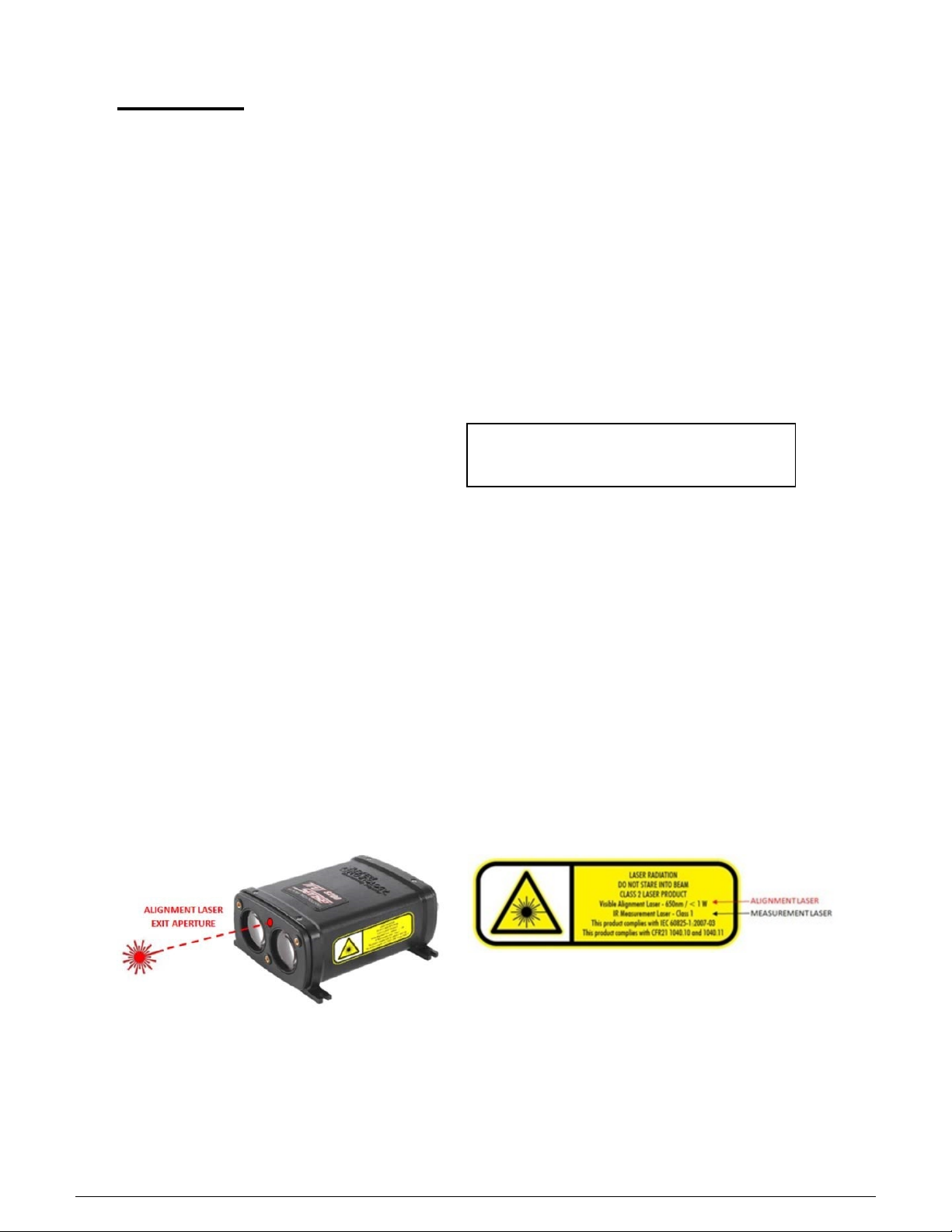

Turn Laser Pointer On (S310 and S330 Only)..........................................................................................................34

$VF

Turn Laser Pointer Off (S310 and S330 Only) .........................................................................................................34

$WU

Warm Up Period ...................................................................................................................................................35

8 APPLICATION REFERENCES............................................................................................................................................. 36

APPLICATIONEXAMPLES ...............................................................................................................................................................36

HARTCOMMUNICATION .............................................................................................................................................................38

SDI-12COMMUNICATION............................................................................................................................................................39

9SPECIFICATIONS ........................................................................................................................................................40

10 ERROR CODES ........................................................................................................................................................... 41

11 TROUBLESHOOTING .................................................................................................................................................. 41

12 CARE AND MAINTENANCE.........................................................................................................................................42

OPERATING TEMPERATURE...........................................................................................................................................................42

MOISTURE AND DUST PROTECTION................................................................................................................................................42

CLEANING .................................................................................................................................................................................42

RETURNING SENSOR FOR REPAIR ...................................................................................................................................................42

13 DIAGRAMS - WIRING AND PINOUTS.......................................................................................................................... 43

7054674 OEM CABLE ...............................................................................................................................................................43

7054671 EXTERNAL CABLE:12 VPOWER DOWNLOAD CABLE........................................................................................................44

4824758

C

ABLE

I

NTEGRATION

C

ABLE WITH

L

EADS

......................................................................................................................45

7054691EXTERNALCABLE:RUGGEDIZEDENCLOSURE TERMINAL BLOCK CABLE.......................................................................................46

S330 4-20 CABLE WITH OPTIONAL PC CONNECT (1 OF 2) ..................................................................................................................47

S3304-20 RUGGEDIZEDENCLOSURE TERMINAL BLOCK WITH OPTIONAL PC CONNECT (2 OF 2) ..................................................................48

S300 /S310 I/O TRIGGER CABLE WITH OPTIONAL PC CONNECT (1 OF 2)...............................................................................................49

S300/S310 I/O TRIGGER RUGGEDIZED ENCLOSURE TERMINAL BLOCK W/OPTIONAL PC CONNECT (2 OF 2) ...................................................50

S300/S310 SDI-12RUGGEDIZED ENCLOSURE TERMINAL BLOCK WITH OPTIONAL PC CONNECT (1 OF 2).....................................................51

S300 /S310 SDI-12 CABLE WITH OPTIONAL PC CONNECT WIRING DIAGRAM (2 OF 2)............................................................................52