2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������3

3 Functions and features ����������������������������������������������������������������������������������������4

4 Function���������������������������������������������������������������������������������������������������������������5

4�1 Processing of the measured signals��������������������������������������������������������������5

4�2 Switching function������������������������������������������������������������������������������������������5

4�3 Diagnostic function ����������������������������������������������������������������������������������������6

5 Mounting��������������������������������������������������������������������������������������������������������������6

5�1 Mounting accessories������������������������������������������������������������������������������������6

5�2 DIN rail mounting�������������������������������������������������������������������������������������������7

5�3 Rear panel mounting �������������������������������������������������������������������������������������7

6 Electrical connection��������������������������������������������������������������������������������������������8

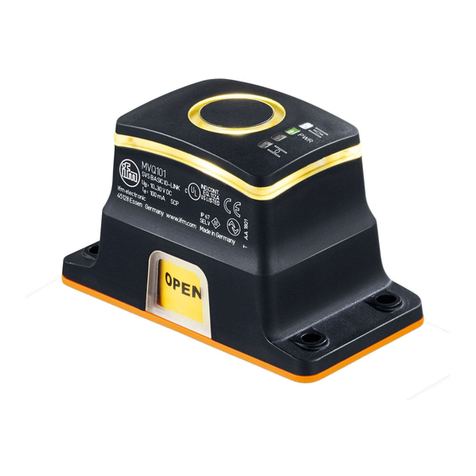

7 Operating and display elements ��������������������������������������������������������������������������9

8 Menu������������������������������������������������������������������������������������������������������������������10

8�1 Menu structure���������������������������������������������������������������������������������������������10

8�2 Explanation of the menu������������������������������������������������������������������������������ 11

9 Parameter setting ����������������������������������������������������������������������������������������������12

9�1 General parameter setting���������������������������������������������������������������������������12

9�2 Setting of the output signals ������������������������������������������������������������������������14

9�2�1 Setting of the unit of measurement for system pressure ��������������������14

9�2�2 Setting of the output function��������������������������������������������������������������14

9�2�3 Setting of the switching limits (hysteresis function) ����������������������������14

9�2�4 Setting of the switching limits (window function) ��������������������������������14

9�3 User settings (optional) �������������������������������������������������������������������������������15

9�3�1 Setting of a time delay for the switching signals���������������������������������15

9�3�2 Setting of the damping for the switching outputs��������������������������������15

9�3�3 Configuration of the display ����������������������������������������������������������������15

9�3�4 Zero point calibration ��������������������������������������������������������������������������16

9�4 Service functions �����������������������������������������������������������������������������������������16

9�4�1 Reading of the min/max values for system pressure��������������������������16

9�4�2 Reset of all parameters to factory setting �������������������������������������������16