3

Controls

2

www.lasertools.co.uk

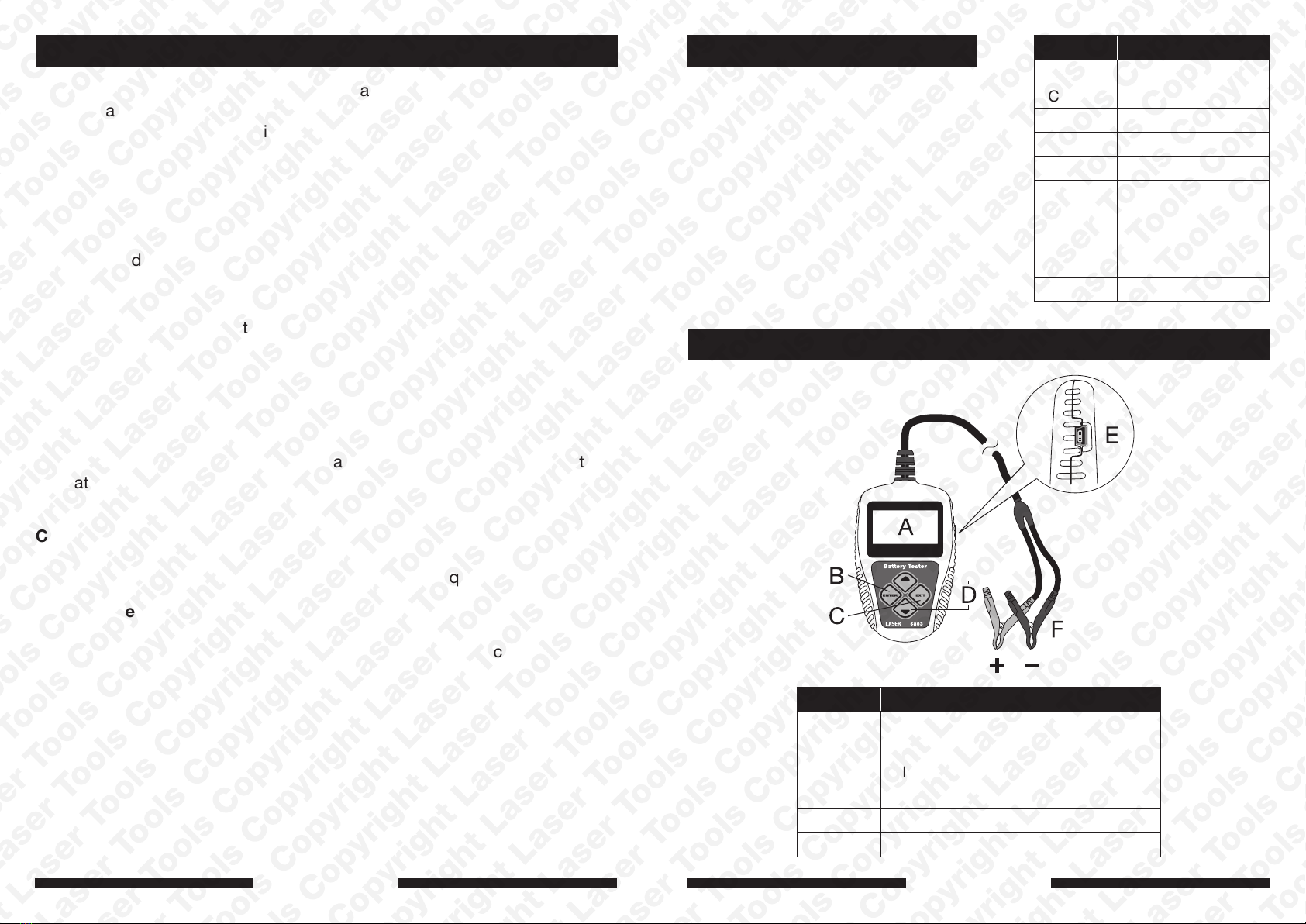

Technical Parameters Standard Measuring Range

CCA 100-2000

BCI 100-2000

CA 100-2000

MCA 100-2000

JIS 26A17-N200z

DIN 100-1400

IEC 100-1400

EN 100-2000

SAE 100-2000

GB 30Ah-220Ah

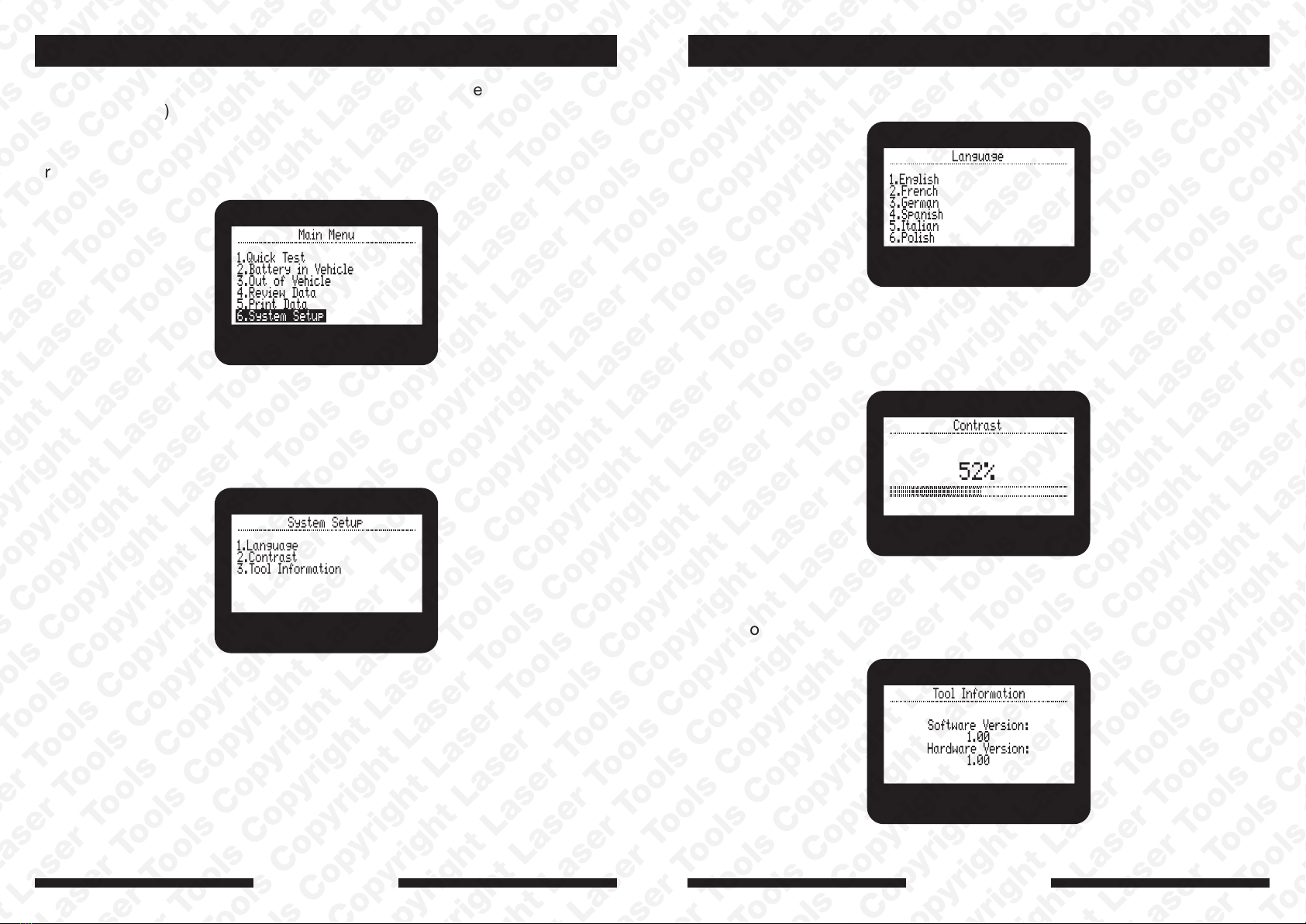

Introduction

The Laser 6803 Car Battery Tester quickly and accurately measures the cold

cranking amps (CCA) capability of the vehicle starting battery, measures

battery health and assists in pinpointing common faults in the vehicle

starting and charging systems.

• Tests all automotive starting batteries, including lead-acid, AGM

(absorbed glass mat) flat plate, AGM spiral wound, GEL batteries, and

EFB (enhanced flooded battery)

• Detects bad cells

• Reverse polarity protected — will not damage battery tester or vehicle

• Tests fully charged or partly discharged batteries

• Multi language

• Test data can be printed out via PC or Laser 6804 Thermal Printer

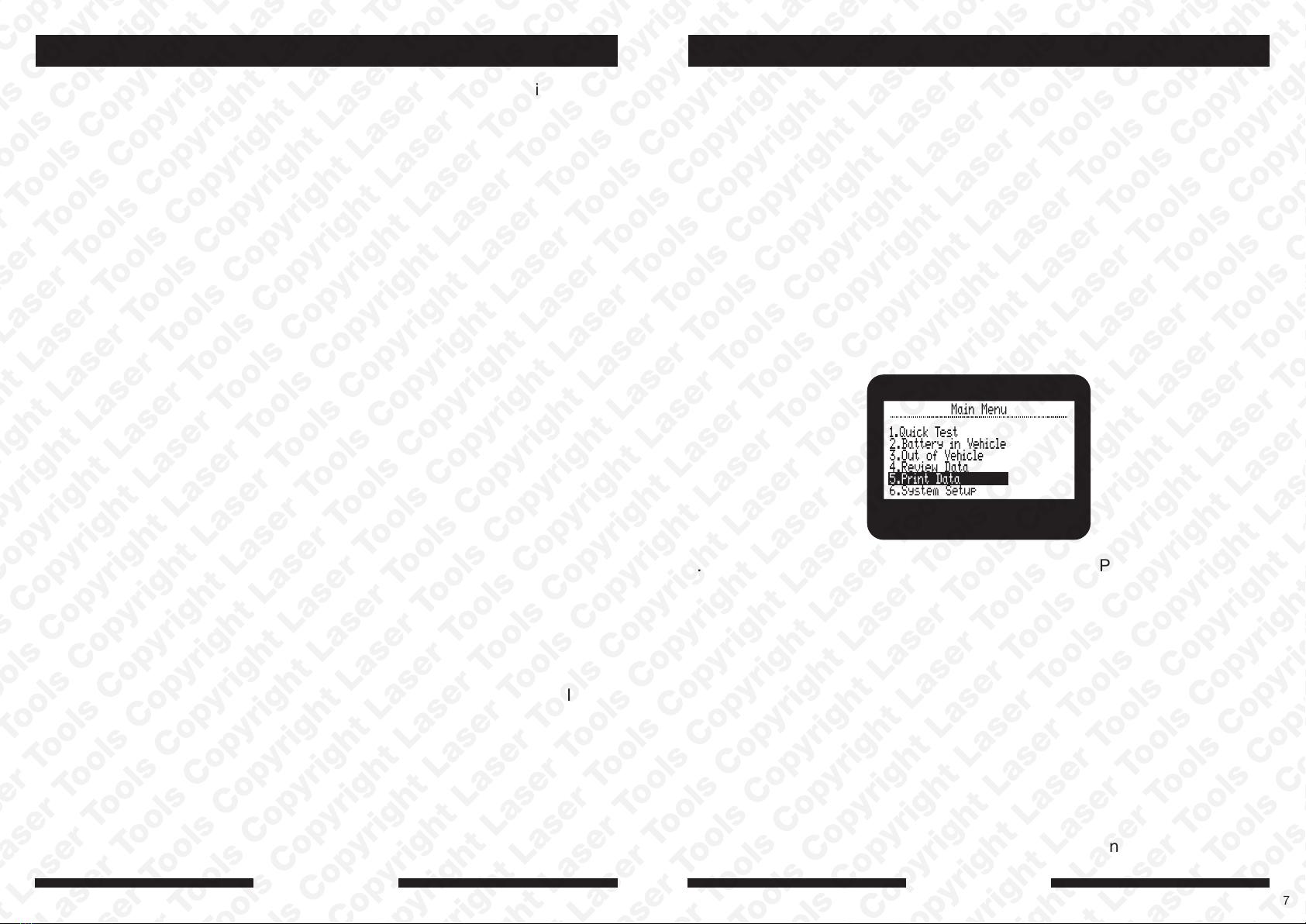

Battery Test

Analyses battery health status to calculate actual cold cranking capability of

the battery; advises whether to charge or replace battery if necessary. Can

identify a faulty battery before actual failure.

Cranking Test

Identifies fault or potential faults in the starting circuit including the starter

motor itself by measuring increases in starting load torque.

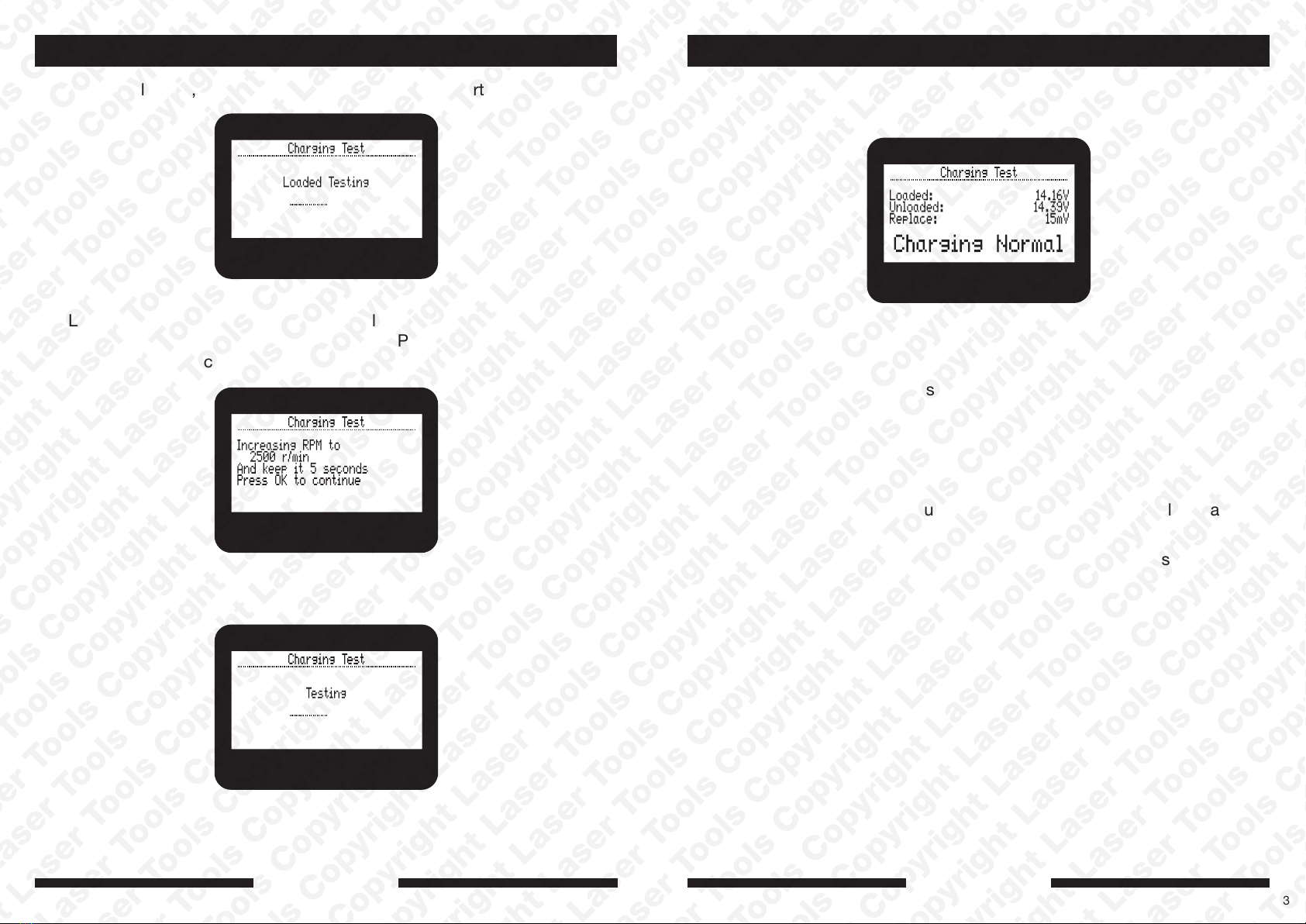

Charging Test

Checks and analyses the charging system, determines if output of generator

or alternator is to normal parameters, detects under or over-charging.

www.lasertools.co.uk

Cold cranking amps measuring range:

Voltage measuring range: 8-30V DC

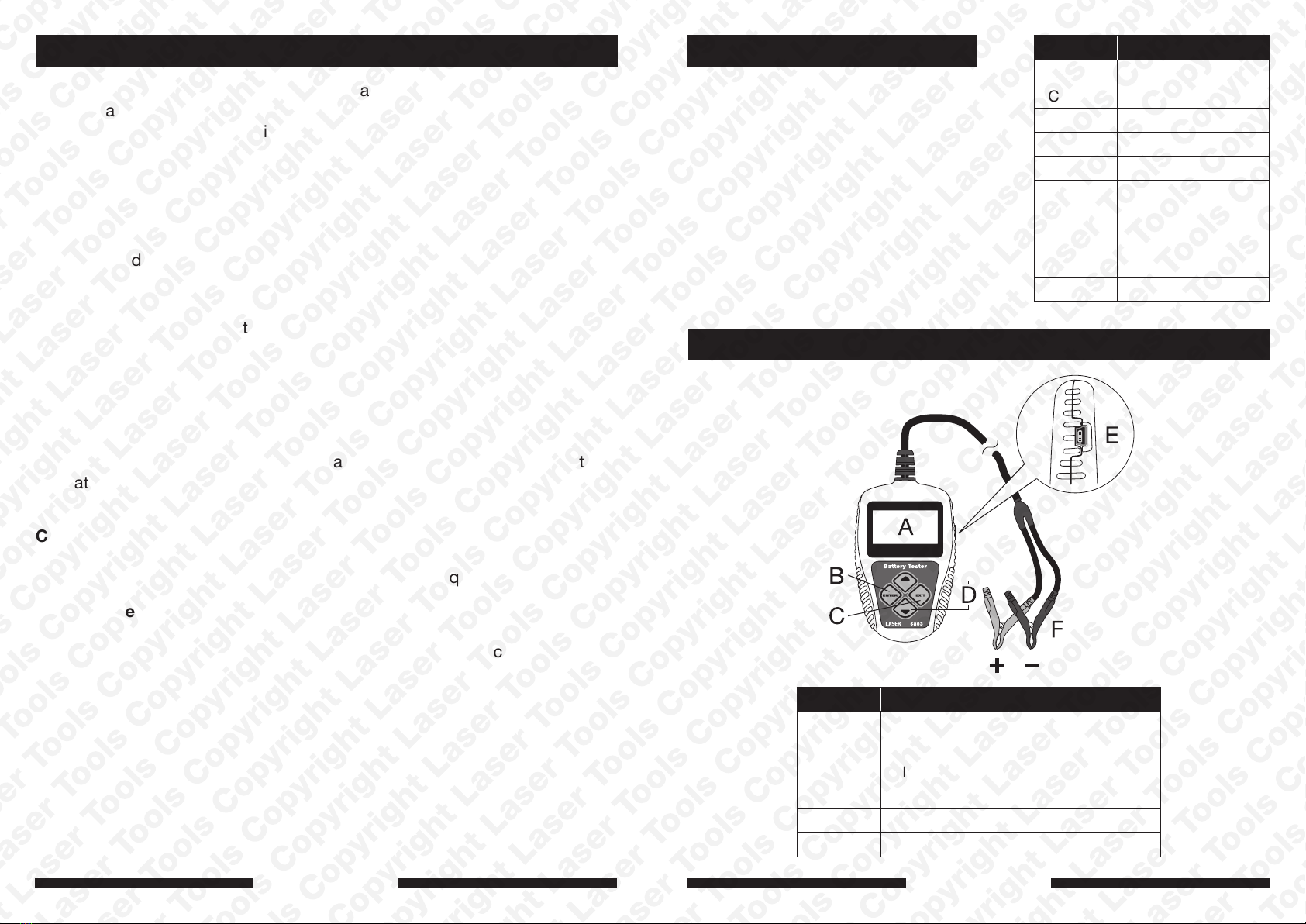

Ref. Component

A LCD display screen

B ENTER key

C EXIT key

D UP / DOWN keys

E Mini-USB socket

F Battery Crocodile clips (+ red & - black)