Type

321A

SECTION I

CHARACTERISTICS

lntrodudion

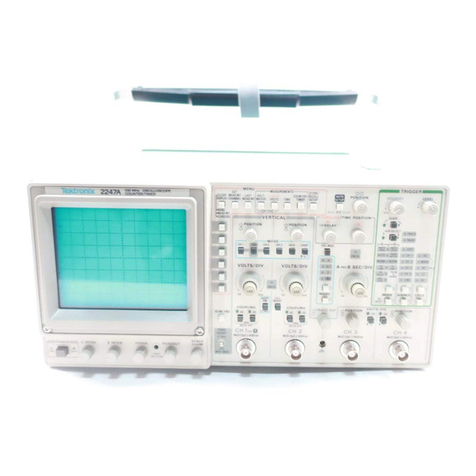

The Tektronix Type 321A

is

a high-performance,

dc

-to-6

me, transistorized oscilloscope. Its light weight, small size

and

ability to

operate

from o variety

of

powe

r sources

make

it a versatile field

and

laboratory instrument. The oscillo-

scope

con

operate

from its internally-contai

ned

rechargeable

battery

pock, on external

de

source

or

from o 115/230-vo

lt

50-800 cycle

ac

line. Regulated

power

supplies

in

the

instru-

ment, accur

ate

calibration,

and

precise linearity assure

exa

ct

time

and

amplitude measurements despite normal voltage-

source

and

powe

r-

supply-lo

ad

changes

that

occur under

odual

operating

conditions.

Operating

temperature

range

derived from tests

in

dicates

optimum performance

and

reliability on its self-

conta

i

ned

batteries from

o·

to + 40° c

ot

altitudes up to 15,000 feet.

Temperature

range

without batteries when

opera

ting from

on

external source

is

-

15

• C to

+55

• C. Non-operating tem-

perature

range

is

-55"

C to

+7

5"

C without

batteries

and

-40•

C to +

60"

C with batteries

at

alt

itu

des

to

50

,

000

feet.

For

the

operator's

convenience, a front-panel

battery

lighl

in

dicates when the internal batteries o

re

low.

If

external

de

or

ac

operation

is

being

used instead

of

the batteries,

the

light turns on

if

the external volt

ag

e source

drops

too

low

for

proper

power

supply regulation.

A 4-position

power

switch on the front panel permits

convenient selection

of

charging

rote

and

/or

power

source.

Vertical Deflection

System

Bandpass-De to

at

least 6 me (3-db down) using

de

cou-

pl

in

g; using

oc

coupling, low-frequency

3-db

down

po

in

l

is 2cps typical from a 1-kc reference.

Sensitivity-0.01

v/div

to 20

v/div

in

11

calibrated

steps;

occurocy is within

3"/o

of

front-

pane

l markings. Con-

tinuously variable from 0.

01

v/div

to

abou

t

50

v/div

uncolibroted.

Input lmpedanc

e-35

pf nominal

paralleled

by 1

megohm

(:.t 1

"/o),

8.2

pf nominal paralleled

by

10

megohms

(±2%1

when using the P6006

lO

X Probe.

Maximum Allowable Input Voltage

Roting-600

volts com-

bined

de

and

peak

oc

; 600 volts (not 1200 volt

s)

peak-to-

peak

oc

.

Triggering

Type-Automatic,

or

amplitude-level selecti

on

using

pre

-

set

stability.

Modo-Ac

-c

oupled

or

De-coupled.

Slope-P

lus, from rising slope

of

triggering waveform,

or

minus from negative slope

of

triggering waveform.

Source-Internal from vertical signal,

or

external from

triggering signal.

Signal Requirements-Internal: 0.2

majo

r division vertical

deflection at 1kc increasing

to

1

major

division

at

6 me.

External: 1 volt peok-to-peak

at

l kc increasing to 3 volts

peak

-to-peak

at

6 me. Nominal input impedance: 5 pf

paralle

l

ed

by

100 kilohms (± 20%).

Sweep

Type-Miller Integrator.

Sweep

Rotes-0

.5JLsec/div

to

O.S sei:/div in 19 c

alibrated

steps. Accurate

5X

sweep

magnifier extends calibrat

ed

range

to

0.1

p.sec/div.

Calibrated

sweep-rote accuracy

is :

t:

3"/o.

Sweep time adjustable between steps

and

to

~

1.5

sec/div

uncolibrated.

External

Ho

rizontal Input

Bandpas

s-

De

to

at

least 1 me (3-db down).

Deflection

Foetor-!

vfdv

+

10"/o

with 5X magnifier

an

.

Input

lmpedanc&-30

pf

typical paralleled by 100 kilohms

1±

5%

).

Amplitude Calibrator

Square

Wove-Frequency

about

2

kc.

Amplitud

e-500

mv

peak

-

to

-pe

ak

. Also

40

mv peok-to·

peak

internally coupled in CAL4

DIV

position

of

VOLTS/

DIV

switch. Peak-to-

peok

amplitude accu

racy

is

±

3%

.

Cathode-Ray Tube

Typ

e-Speci

al Tektronix-manufactured 13211.

3"

flat-face,

post-deflection

acce

le

rator

. l

ow

healer

power

.

Accelerating

Potcntiol-4

kv.

Z-Axis Modulation-External terminal permits

RC

coupling

to

crt grid.

Unb

lonking

-Defle

ction unblanking.

Phosphor-Type

P31

normally furnished; PI,

P2

, P7,

and

Pl

l phosphors optional.

Other

phosphors furnished on

special

order

.

Graticule

Illumination-Variable

edge

lighting

when

operating

from

ac

line.

Display

Area

-Marked

In

6-vertical

and

10-horizontol 1

/4"

divisions.

Power Requirements

Source-Operates

from I0 size D flashlight cells,

or

10

size D

rechargeable

cells (approximately 3 hours using

2.5

ampere

-hour cells; approximately 5 hours using 4

1-1