CALIBRATION UNIT FOR PERSONNEL TESTERS

Installation, Operation and Maintenance

UNIT C, 4TH DIMENSION, FOURTH AVENUE, LETCHWORTH, HERTS, SG6 2TD UK

Phone: 0044

(0) 1462

672005, Fax:

0044 (0)

1462 670440

• e-mail:

[email protected], Internet: Vermason.co.ukTB-7543 January 2011 Page 1 of 2 © 2011 Vermason

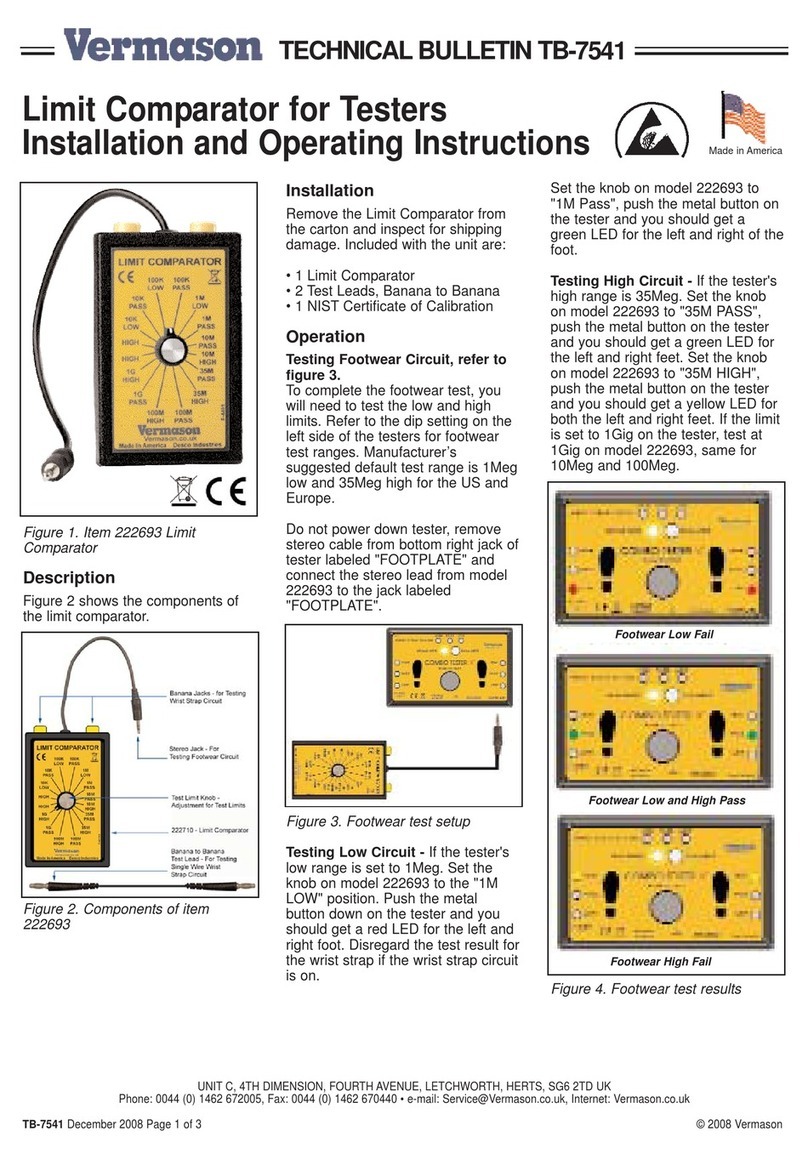

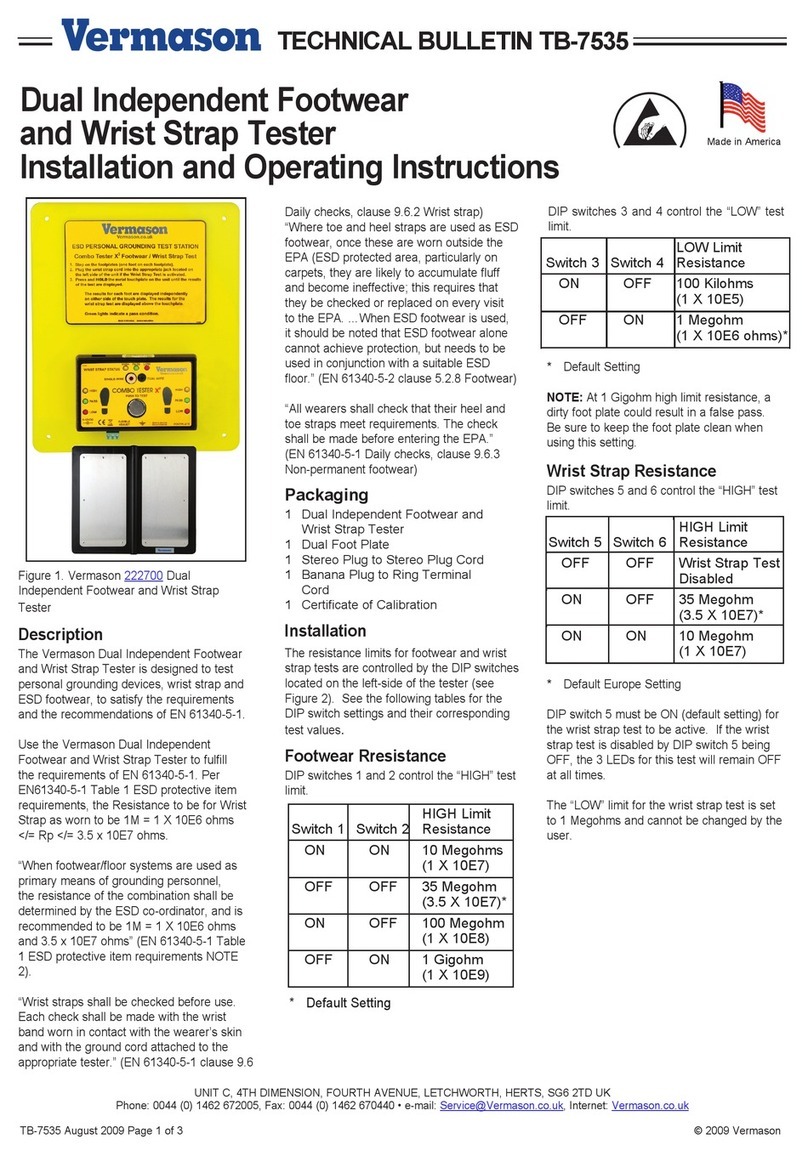

Figure 1. 223002 calibration unit.

Description

The Vermason calibration unit is

essentially a resistance box to be

used for calibrating either a wrist

strap tester or a footwear tester. The

calibration unit is set to cover limits

as specified in EN61340-5 and ANSI/

ESD S20.20. The unit is supplied

with a socket-to-socket adaptor and

a test certificate.

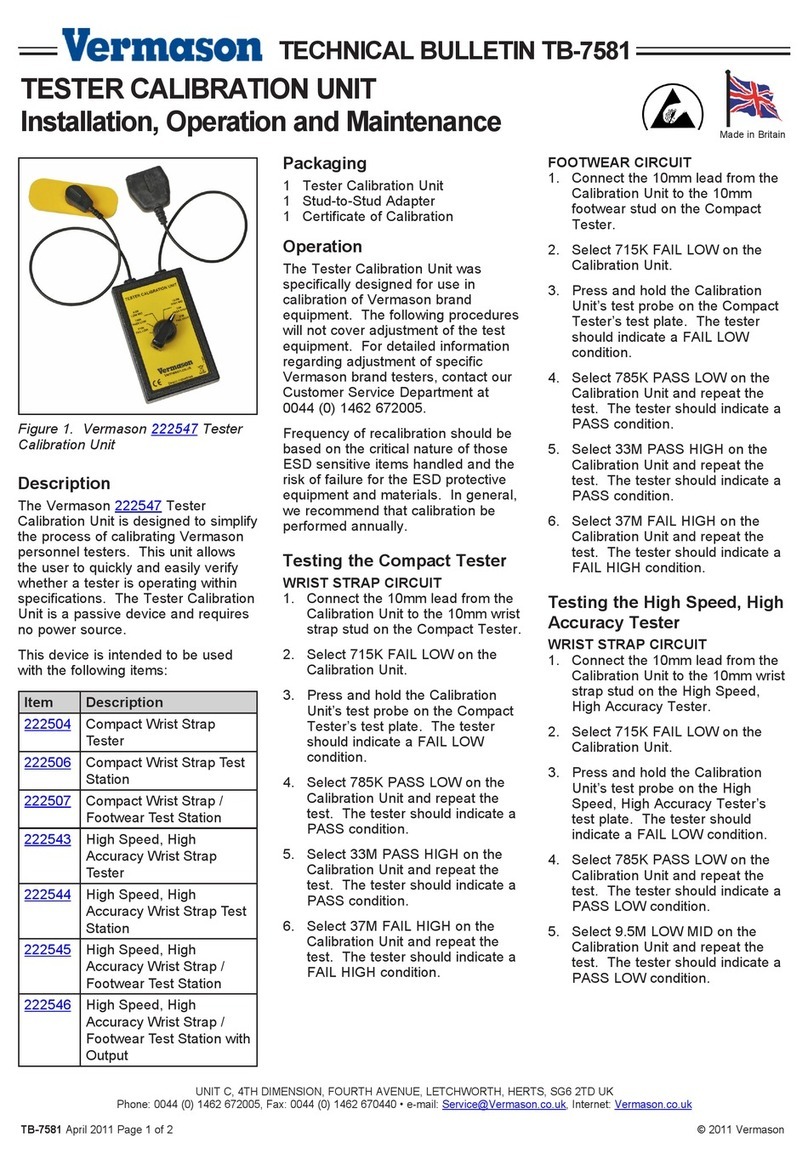

This device is intended to verify the

settings of Vermason testers 222508,

222514, 222518 and 222535. If a

faulty unit is found it is recommended

that you return the unit to Vermason

Ltd for recalibration. If you wish to

perform recalibration yourself, it is

possible using a method of trial and

improvement.

Inspection

Remove the calibration unit from

the carton and inspect for shipping

damages. Each unit includes the

following:

1 Calibration unit, item #223002

1 10mm socket to 10mm socket

adaptor

Calibration Test Procedures

The calibration unit was specifically

designed for use in calibration of

Vermason brand test equipment.

The following step by step

procedures will cover calibration for

specific test units. The procedures

will not cover adjustment of the test

equipment. For detailed information

regarding adjustment of specific

Vermason brand testers contact our

Customer Service Department at 00

44 (0) 1462-672005.

How to test a wrist strap

tester

1. Connect the calibration unit lead

that is terminated with a 10mm

socket to the 10mm stud of the

tester.

2. Turn the knob to the ‘FAIL LOW’

setting on the upper part of the dial

marked ‘Wrist strap’.

3. Place the probe with the

conductive rubber base onto the

test button of the tester, making

sure that the probe is placed in the

middle of the test button for

optimal reading.

4. Push and hold the probe onto the

test button.

5. The tester should indicate ‘FAIL

LOW’

6. Repeat this procedure for the

other wrist strap knob settings, in

each case the indication on the

instrument should correspond to

the knob setting. (Note that the

“Low mid” and “High mid”

positions refer to the “<10

megohms” and “<35 megohms”

thresholds of the tester.)

7. If the response is different to the

one selected, the tester will need

to be re-calibrated.

8. If the response is as expected

release he test button and switch

the calibration unit to the next

limit.

How to test a footwear tester

1. When calibrating the footwear

tester use the adapter supplied to

connect the tester lead to the

calibration box.

2. Repeat the same procedure as

above for wristband, but use the

footwear side of the calibration

box.

Recalibrating a faulty tester

1. If a tester is found to be out of

calibration it is recommended that

you return it to Vermason Ltd for

recalibration. If you wish to adjust

calibration yourself you may follow

this procedure.

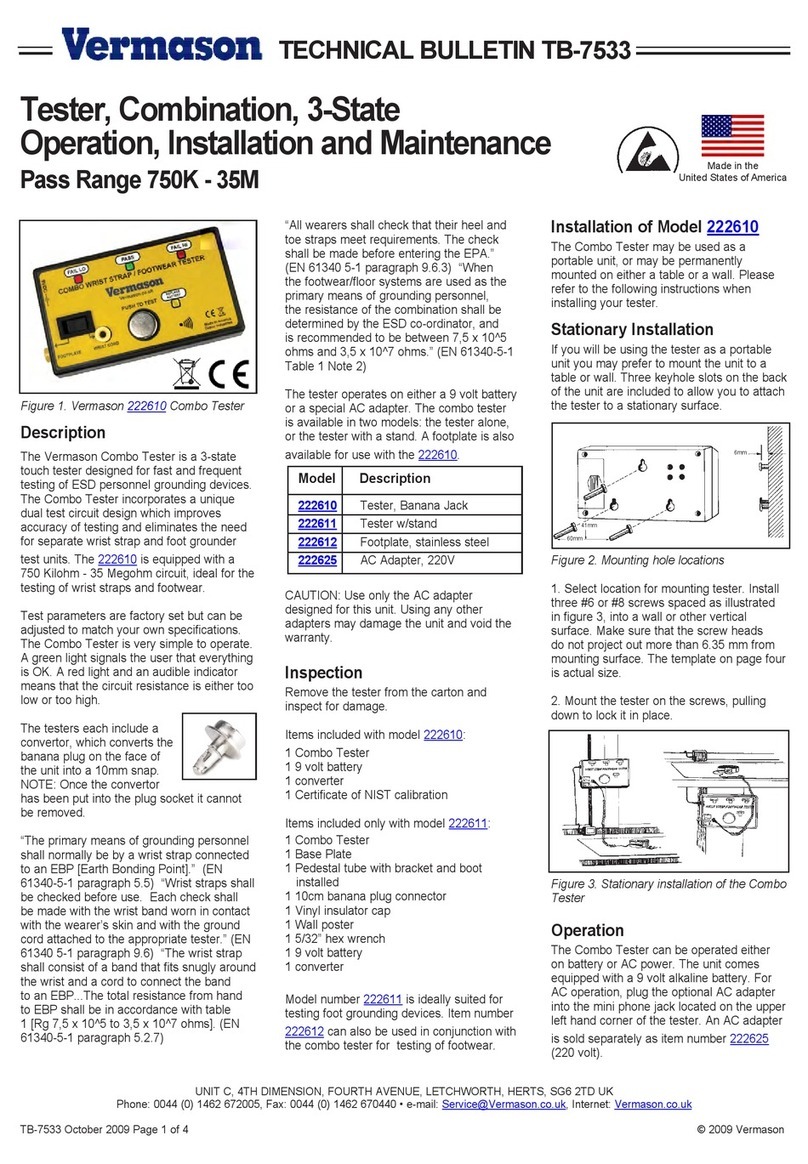

2. Adjustments are made via two trim

pots, which can be accessed via

holes on the left hand side of the

unit. The lower trim pot adjusts the

10 megohms and 35 megohms

limits. The upper trim pot adjusts

the 100 kegohms and 750

kegohms limits.

3. The trim pots adjust the footwear

and wrist strap circuits

simultaneously.

4. Adjust the trim pots in ¼ turn

increments. When you have made

a change repeat the test to see if

you have adjusted sufficiently.

5. If the LED to the left of the

expected LED is illuminating turn

the relevant trim pot clockwise. If

the LED to the right of the

expected LED is illuminating turn

the pot anti-clockwise.

6. When you have adjusted the trim

pot enough test the associated

position on the calibration unit to

ensure you have not adjusted too

far.

7. When complete perform a full set

of tests again.

TECHNICAL BULLETIN TB-7543

Made in Britain