Operation Section

1-Safety

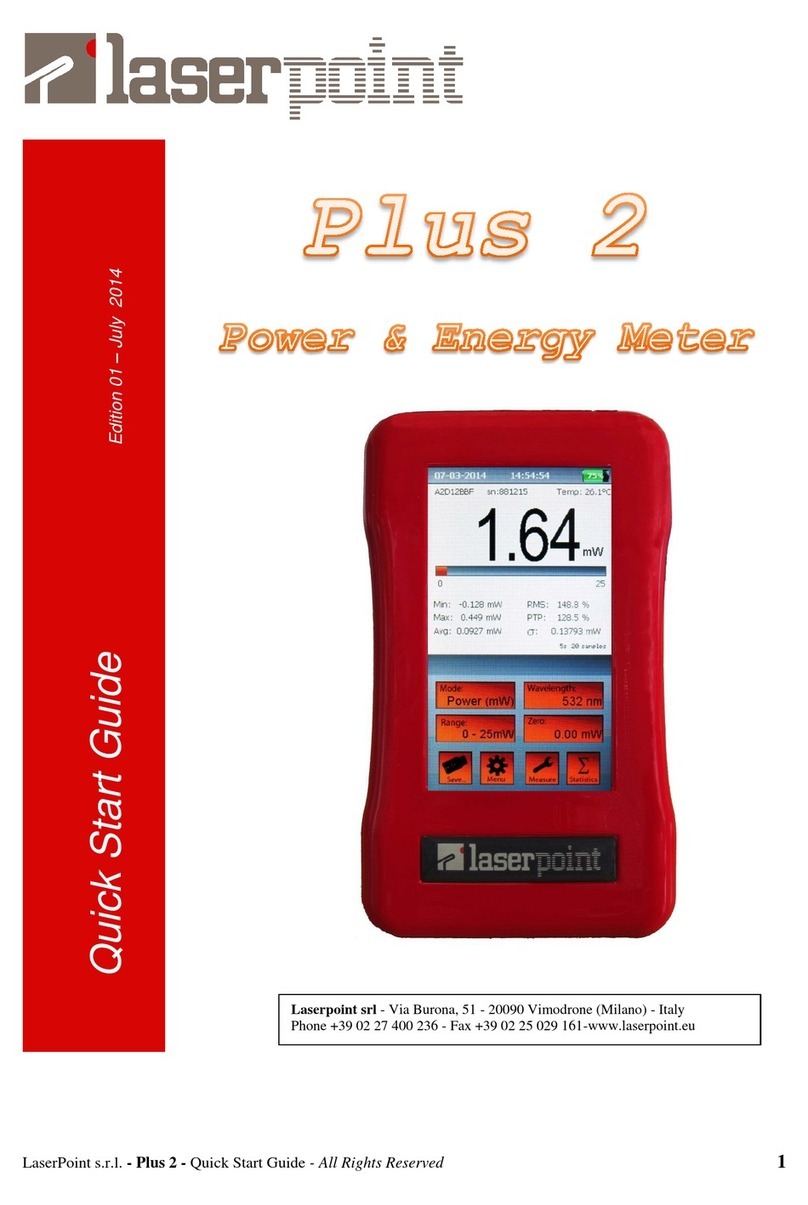

Take all the required safety procedures needed when

working with laser beams and wear protection glasses all

the time! The laser beam must hit ONLY the sensor head

front side. Avoid to incidentally expose the protected

stainless steel stem to the laser beam as dangerous back-

reflections can be produced! Never touch the sensor head as this part can reach

70°C of temperature!

In the case the laser power density is close to the damage threshold of the head

absorber coating, damages like coating discoloration or underlying metal melting

could occur. In both cases consult LaserPoint.

2-Starting the Instrument

To switch on the instrument, keep the ON/Zero button

pushed until the LCD shows the Fit Model (Fit 50, Fit 200,

Fit 500 shown in 2 steps), then release it (this step takes

approximately 2 seconds). The instrument will also display one of the 2 available

laser wavelengths: e.g. CO2. The wavelength displayed the first time is random;

to change it refer to Paragraph 10 of this section.

3-Auto-check Cycle

When the ON/Zero button is released, the instrument starts

an auto-check cycle during which both circuit and display

are controlled and reset. During this cycle, the LCD shows

all available segments of alphanumeric characters and the

bar graph at full scale. Upon completion of this cycle, the LCD displays the last

recorded value of measured power.

4-Zeroing/Resetting

Before starting the first measurement or a new one, the

instrument needs to be zeroed; to do so, just push and soon

release the ON/Zero button. After the LCD has displayed

“CAL”, the lateral LED turns steady green and “FIT”

blinks. Any previously recorded value is zeroed and the instrument is ready to

measure.

An automatic Zero is performed by Fit after every measurement.

4

5-Measurement Cycle

Check the laser shutter is closed; align the probe to the

laser beam path and start the measurement cycle by opening

the laser shutter. Avoid taking measurements during laser

warm up or beam instabilities.

The measurement starts automatically. During the acquisition time, “RUN” and the

LED both blink for approximately 5 seconds. The bar graph indicates the head

temperature on an arbitrary scale.

6-Measurement Display

As soon as the measurement is over the LED turns into

steady red. Remove the probe from the laser beam: the

display shows the actual power, and the remaining thermal

capacity. If the bar graph is below full scale, one or more

measurements can be carried out before the sensor head needs to be cooled.

Approximately after 10 seconds the LED automatic shuts off. The FIT performs an

automatic Zero and the LED turns steady green. The LCD shows the last measured

power value . Return to Par.5 for a new measurement

7-Cooling the Head

Should the probe reach its limit temperature, the LCD

shows “ COOL” and the LED blinks red. Use

spontaneous or air forced cooling. Never use liquids!!

As soon as the temperature returns below its maximum

allowable limit, the LCD displays the last measured power value.

Warning: sudden cool downs and subsequent strong temperature variations on

the head may cause a re-start of instrument and spurious measurements.

8-Auto Off /Battery Warning

When the battery pack is getting exhausted, its symbol

pops up on the LCD to warns that approx. 10 hours of

residual power remain. Note: to increase the battery life,

the instrument automatically switches off after 5 minutes

of stand by operation.

To retrieve the last recorded value, return to Paragraph 2. After the internal auto

check cycle, the display will show the last measured value.

To intentionally shut the instrument off, keep the ON/Zero button pushed until the

LCD shuts off (this takes approximately 4 seconds).

5