LaserPoint s.r.l.- Plus2 Power & Energy Meter Instruction Manual - All Rights Reserved 3

1. Safety notes

Before operating this instrument, carefully review the following safety information to avoid personal injury and

prevent damage to this instrument or any sensor head connected to it. This instrument does not contain any user-

serviceable parts.

The measuring as well as the use of lasers is potentially dangerous. This instrument may operate over

wavelengths including non-visible laser radiations.

Proper operating practice in accordance with laser manufacturer’s recommendations is crucial; to ensure

correct operating procedures, consult the laser manufacturer and your laser safety officer.

Eyewear and other personal protective equipment must be used in compliance with applicable laws and

safety regulations.

Operate this instrument only within the specified range of operating conditions (refer to chapter 17 for

environmental and operating conditions).

Do not operate this instrument in critical medical environments, in wet or damp conditions or in an

explosive atmosphere.

Do not operate this instrument if in suspect of damage or failures. Refer about damaged equipment to

LaserPoint for qualified service inspection.

2. LaserPoint intelligent connectors

All LaserPoint sensor heads feature an intelligent connector where the relevant data and information pertaining

the sensor head are stored in a built in memory. The head model, its identification number, the head full scale, the

calibration wavelength(s), the head sensitivity spectrum vs wavelength and the head calibration date are all stored

in the connector memory.

In general, detectors feature different sensitivity values at different wavelengths depending on the detector nature

(this is especially true for those based on semiconductor devices), so it is important to account for this when

measuring power and energy values. All LaserPoint sensor heads are calibrated up to the rated power/energy head

full scale at least at one desired wavelength. All sensor heads are now characterised over a large wavelength range

too using a low power broadband source and the obtained sensitivity spectrum is loaded into the smart connector

memory as a table of discrete sensitivity wavelength dependent data.

All standard LaserPoint thermopile and semiconductor sensor heads are equipped with a DB 15 pin intelligent

connector.

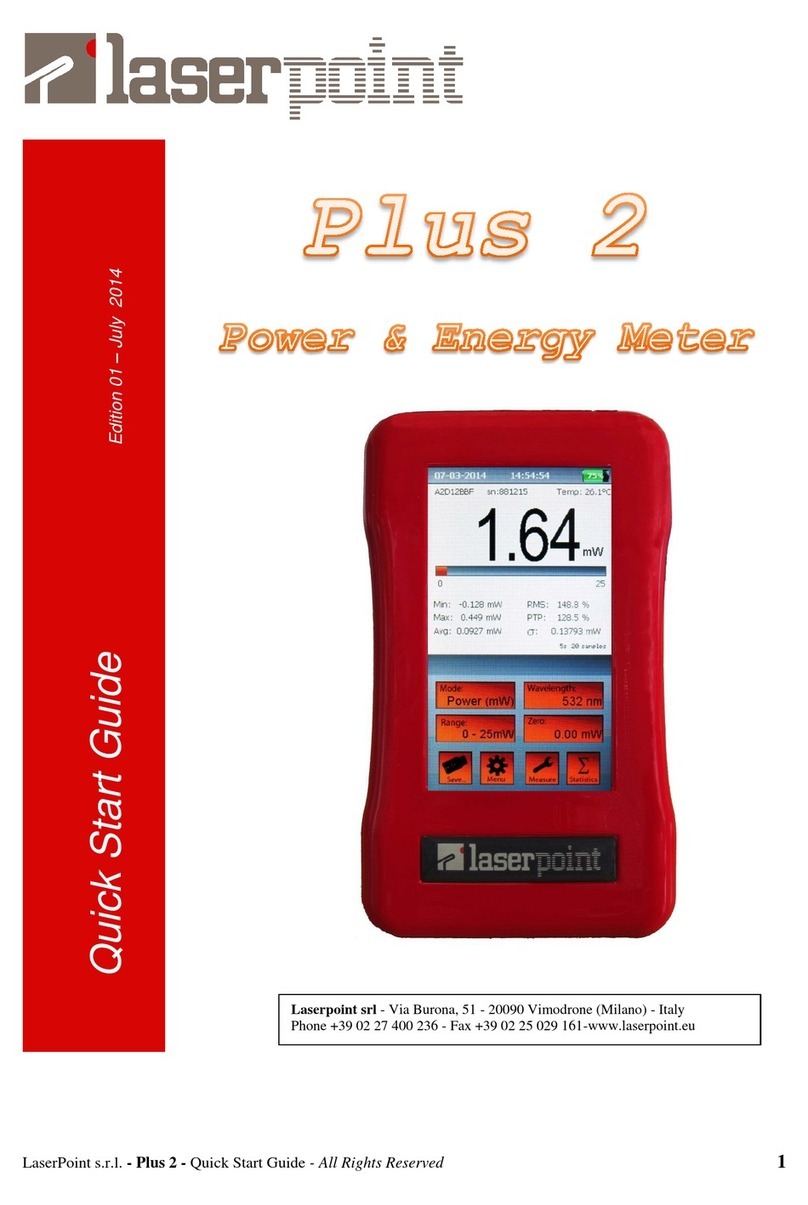

3. Introduction to Plus 2Power/Energy Meter

Plus 2 is an ergonomic micro computer based instrument with a high brightness, 4.3”- high resolution (480 x 272)

TFT LC touch screen display. It is powered by a Li-Pol rechargeable battery. The battery recharge is carried out

by connecting its USB connector cable to a PC or to the supplied line charger/power supply USB port.

Plus 2 keeps in memory all sensor head data and settings up to ten different heads that have been connected to the

instrument; a further head connection to the instrument, displaces the first head data from the intelligent connector

memory and records the last connected head settings. Plus 2 features a high speed algorithm suitable to accelerate

the response and the recovery of thermopile sensor head signals.

The colour touch screen display on the front side of the instrument is the actual user interface; it can be operated

by simple and very intuitive actions. It allows the user to easily interact with the instrument and quickly set it up

for measurements. A stainless steel stand gives the instrument an optimum tilt to offer the best screen view when

the instrument is used on a laboratory table.