2. BEFORE INSTALLATION

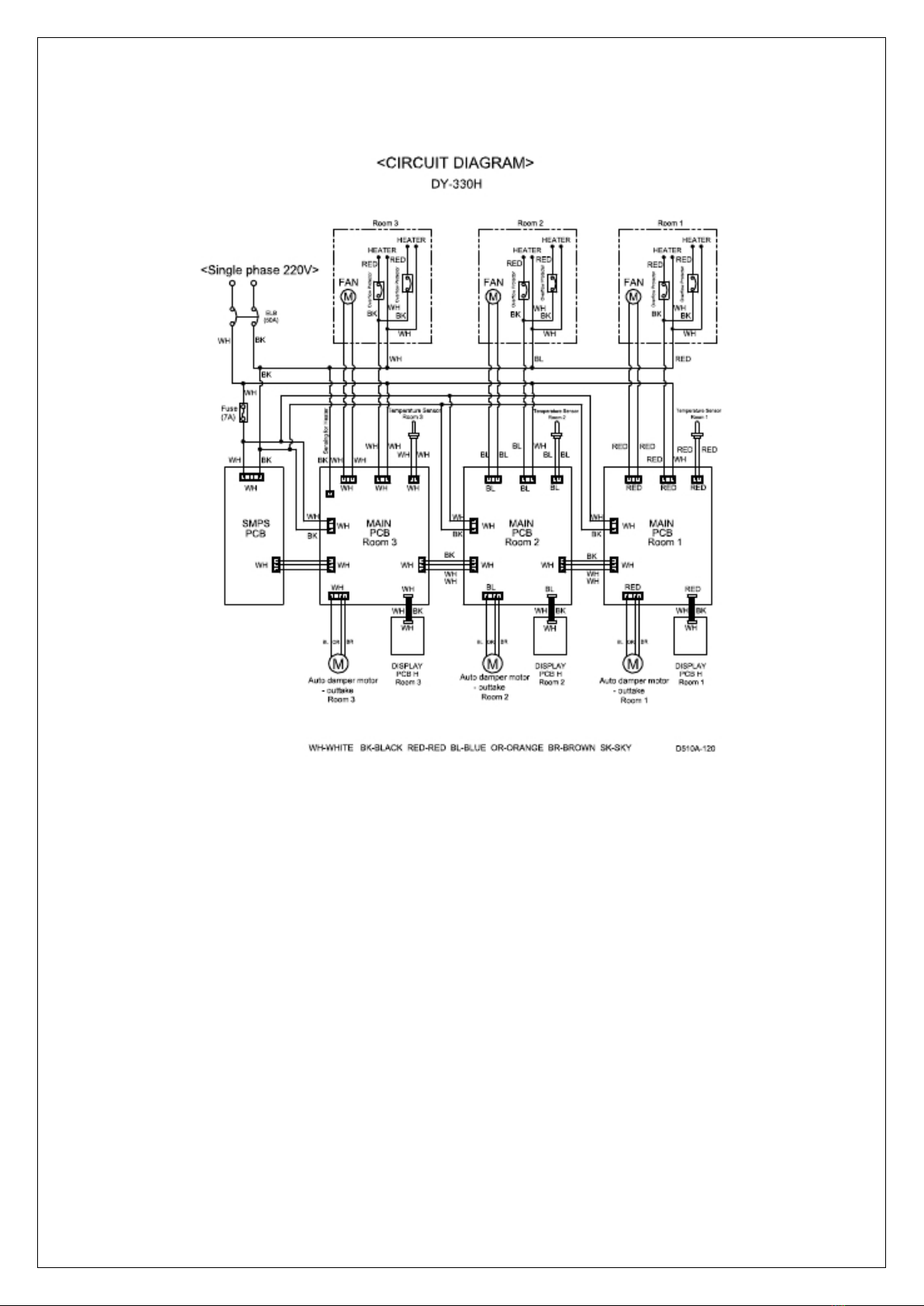

● When exchanging electrical parts or getting a repair, pull the power plug out first.

● When exchanging electrical components, use rated parts.

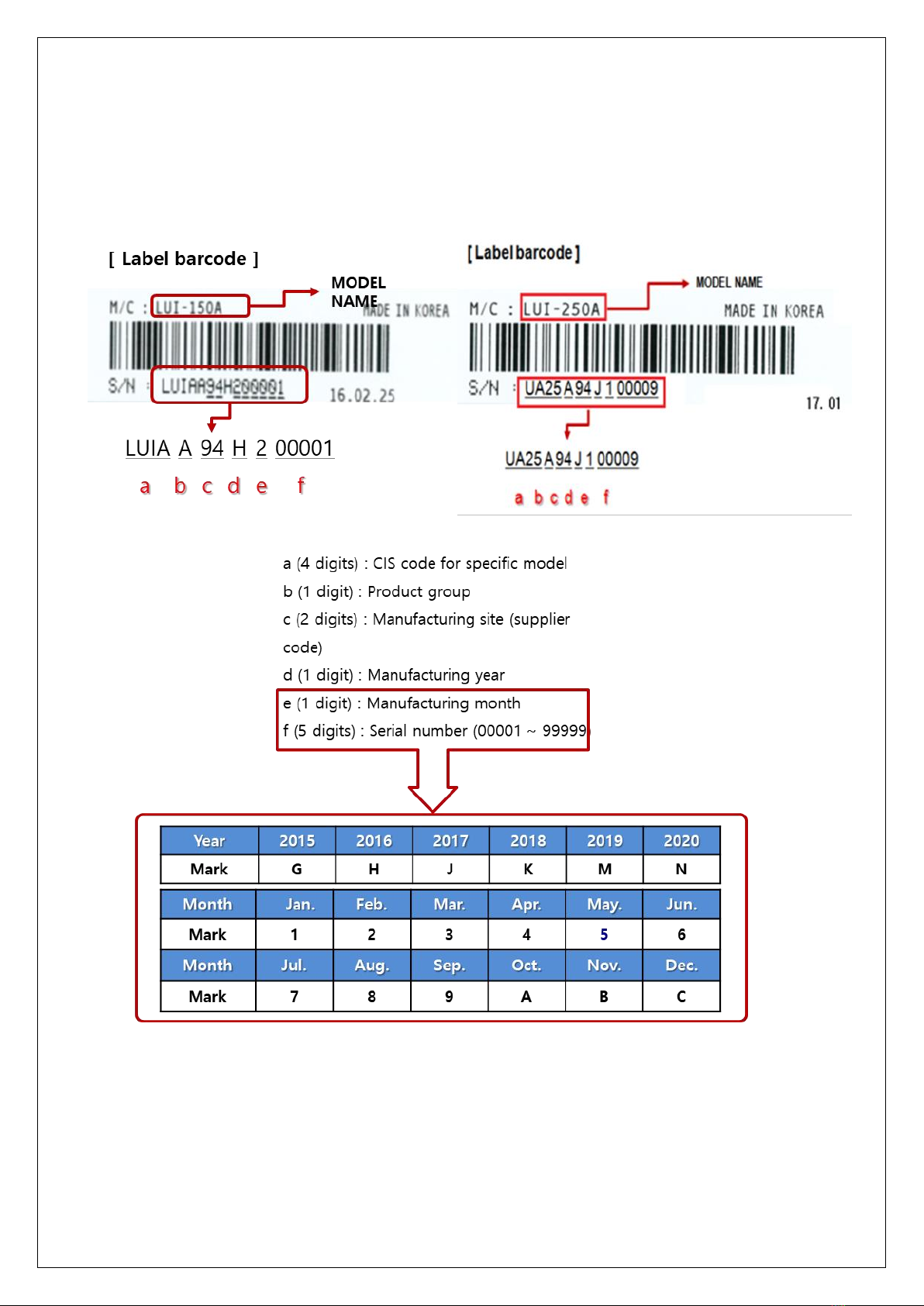

- Be sure to check model name, rated voltage, rated current and operating temperature, etc.

● When getting a repair of failure, make it solid not to cause a risk to connections, such as harness,

wire joint, by exposure of a core wire.

- Be sure not to make it leave its post when applying certain force.

● When getting a repair of failure, perfectly remove dust or foreign substance from housing joint,

connection and contact point first. To prevent fire risk, such as tracking, electrical short, etc.,.

● Check whether there is a trace that moisture permeates into electrical parts.

- If there is the trace, please exchange the parts or take the measure of preventing tracking.

● After getting a repair, check the unit is properly reassembled.

- Keep it in the same state as the one before the repair.

● Check the operating environment of the product and change the place, if the environment is not

stable.

- Do not install the dehydrator at the place with lots of moisture and water and, for electric heating

appliance and near the inflammables.

● If ground connection is required, you can ground it.

- If it is judged that there is a risk of short circuit by moisture or water, grounding is necessary.

● For products with high power consumption like heaters, do not use various power plugs on one

multiple socket.