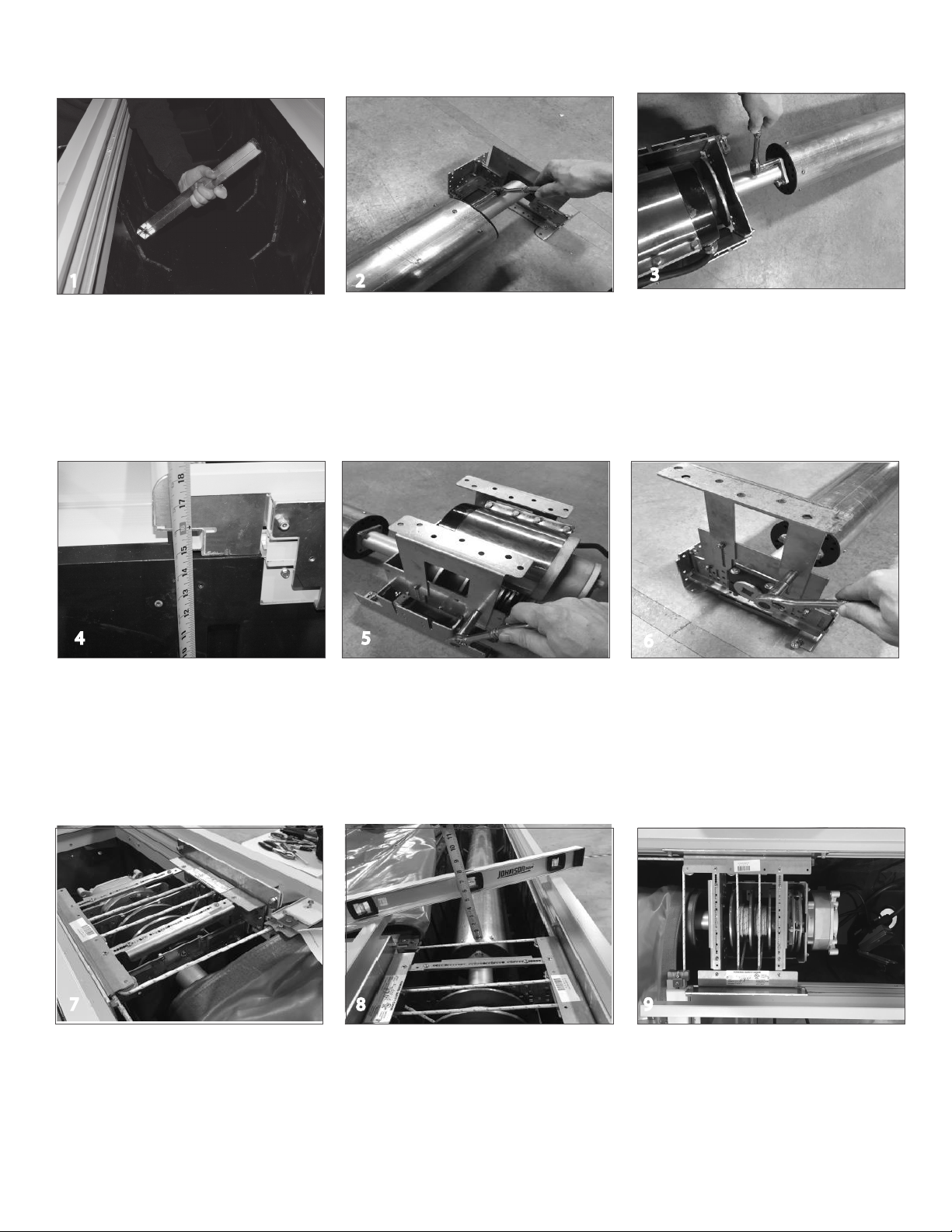

Step By Step Instructions

With the motor end positioned upside

down, install the mounting feet using the

nuts (34) provided.

Positioning the Mechanism Lower

the assembled mechanism with attached

roll-up tube into the cover box and place it

roughly in the position it will anchored.

Note: If the cover box isn’t square to the

pool, position the mechanism in the cover

box so it will be square to the cover track.

12

56

7

Adjusting Mechanism Height

Measure from the bottom of the housing to the

top of the track. The top of the mechanism should

be installed so it is at the same height as the top of

the track. Because the top of the mechanism is

adjustable, use the feet to position the roll up tube

as high as possible in the cover box, but allowing

clearance so the cover won’t rub on the lid

brackets.

Connecting the Roll-up tube

With the non-motor end turned upside

down, attach the cone for the non-motor end

to the roll-up tube using the 3/8” x 1-1/4”

bolts (39) and lock washers (40) provided.

With the motor end turned upside down,

attach the cone to the motor end of the

mechanism using the 3/8” x 1-1/4” bolts

(39) and lock washers (40) provided.

Tighten these bolts with a 9/16” wrench.

Cover Box Preparation

Use a garden hose to clean out the cover

box. During this process, make sure the

water is draining from the cover box. It is

critical that all cover boxes have adequate

drainage. Inadequate drainage may void the

mechanism warranty. If there is no drain or

inadequate drainage in the cover box,

contact your Coverstar Representative.

3

4

Numbers in parenthesis refer to parts shown on page 3.

Install the mounting feet on the non-motor

end using the nuts (34) provided. The top of

the pulley bracket on the non-motor end

should be flush with the top of the track.

With the mechanism and tube assembled

and set in place in the housing, check the

roll-up tube for level. This is crucial to proper

operation of the cover. Position a level

across the housing. Measure from the roll-up

tube to the bottom of the level on both the

motor end and non-motor end of the

mechanism. Adjust height of the non-motor

end feet if needed to level the roll-up tube.

8

Position the mechanism in the cover box so

that the roll-up tube is centered in the

cover box front to back and properly

aligned with the track. The rope should

travel straight from the track to the pulley.

9

© Latham Pool Products, Inc. 2019. All rights reserved.