TEST....................................................................................................................................... 28

ENERGY SAVING .................................................................................................................. 29

DATE AND TIME SETTING.................................................................................................... 29

INFO MENU............................................................................................................................ 29

SETPOINT.............................................................................................................................. 30

PROGRESSIVE PRINTOUTS, TOTALS, OPEN WEIGHINGS ............................................ 30

PROGRESSIVE PRINTOUTS ................................................................................................ 30

TOTALS ................................................................................................................................. 31

OPEN WEIGHINGS................................................................................................................ 31

LORRY DATABASE ............................................................................................................ 32

DATABASE MODIFICATION................................................................................................. 32

PASSWORD ON THE DATABASE........................................................................................ 32

OPERATION ........................................................................................................................ 33

DOUBLE WEIGHING (ENTRY/EXIT) ..................................................................................... 33

1. FIRST WEIGHING (ENTRY) ....................................................................................................... 33

2. SECOND WEIGHING (EXIT) ...................................................................................................... 33

SINGLE WEIGHING ............................................................................................................... 34

SINGLE WEIGHING WITHOUT USING THE DATABASE............................................................. 34

SINGLE WEIGHING USING THE DATABASE .............................................................................. 34

DOUBLE WEIGHING (ENTRY/EXIT) WITH TRAILER........................................................... 35

1. FIRST WEIGHING OF THE TRACTOR (ENTRY)....................................................................... 35

2. FIRST WEIGHING OF THE TRAILER (ENTRY)......................................................................... 35

3. SECOND WEIGHING OF THE TRACTOR (EXIT)...................................................................... 35

4. SECOND WEIGHING OF THE TRAILER (EXIT)........................................................................ 36

SINGLE WEIGHING WITH TRAILER..................................................................................... 37

SINGLE WEIGHING WITHOUT USING THE DATABASE............................................................. 37

SINGLE WEIGHING USING THE DATABASE .............................................................................. 38

MULTIPLE WEIGHING........................................................................................................... 39

1. FIRST MULTIPLE WEIGHING.................................................................................................... 39

2. SUBSEQUENT WEIGHINGS...................................................................................................... 39

3. WEIGHING CLOSING................................................................................................................. 39

SIGNAL STATION.................................................................................................................. 40

ALARMS .............................................................................................................................. 40

PRINTING EXAMPLES........................................................................................................ 42

WEIGHING PRINTOUTS........................................................................................................ 42

COMPLEX FUNCTIONS PRINTOUTS................................................................................... 43

OTHER PRINTOUTS.............................................................................................................. 45

OPTIONS ............................................................................................................................. 46

OPZWTABSTA: PLUSII INTEGRATED PRINTER ................................................................ 46

OPZWTABSTAVQ: STAVQ INTEGRATED PRINTER........................................................... 48

OPZWBATTWINOX / OPZWBATTWTAB.............................................................................. 49

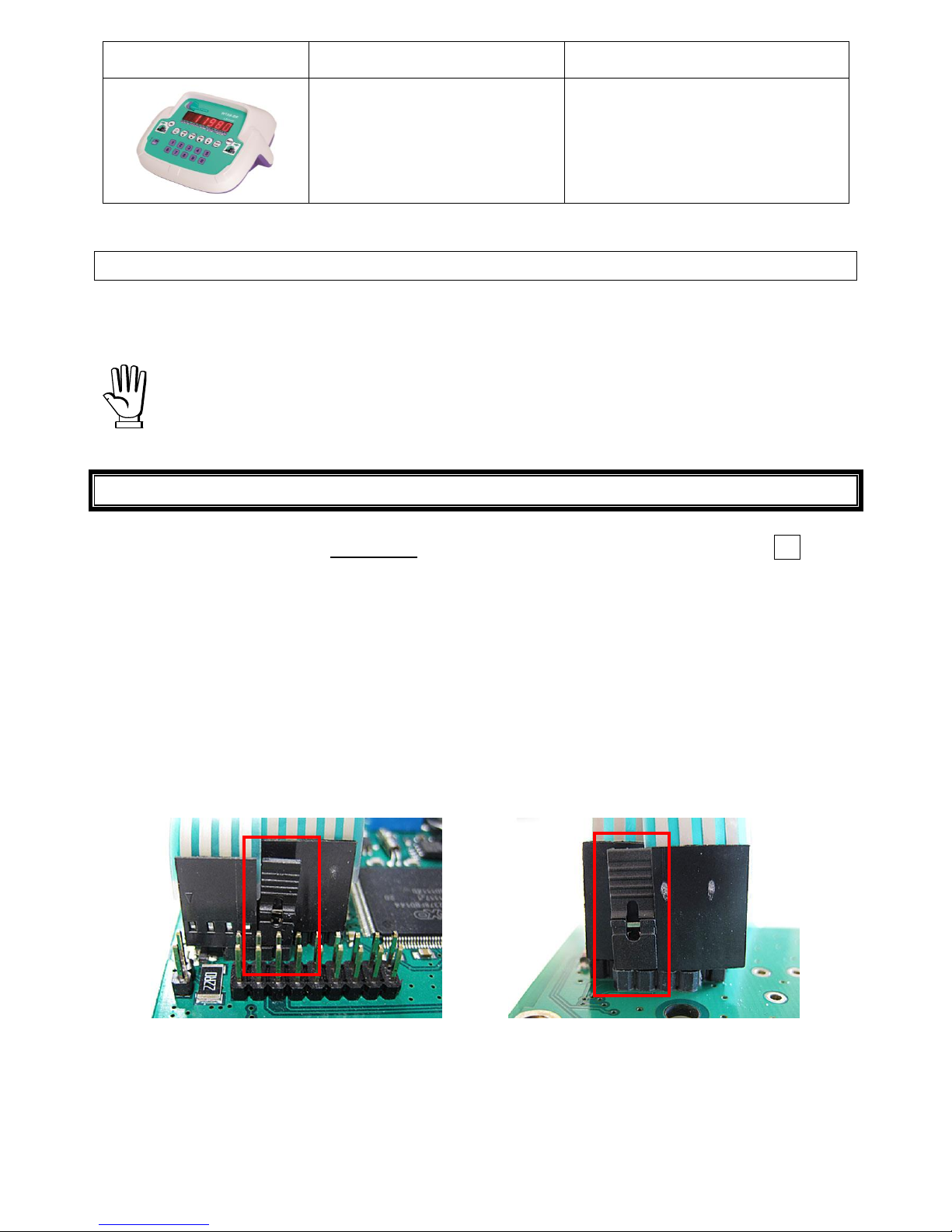

CONNECTING THE BATTERY TO THE INSTRUMENT................................................................ 49

WINOX-BR, WTAB-BR................................................................................................................... 49

WINOX-BL, WTAB-BL ................................................................................................................... 50