Page | 2 of 27

FREMCO A/S

ELLEHAMMERVEJ 14 |DK9900 FREDERIKSHAVN, DENMARK |VAT NO.: DK30815416

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................4

2. GENERAL..................................................................................................................5

2.1. MANUFACTURER............................................................................................................... 5

2.2. THE MACHINE’S DESIGNATION....................................................................................... 5

2.3. MACHINE PLATE................................................................................................................ 5

3. TECHNICAL SPECIFICATIONS.................................................................................6

3.1. MINIFLOW RAPID............................................................................................................... 6

3.2. HYDRAULIC CONTROL UNIT............................................................................................ 7

4. SAFETY DIRECTIONS...............................................................................................8

5. IDENTIFICATION .......................................................................................................9

6. APPLICATION............................................................................................................9

7. MOUNTING ................................................................................................................9

8. SUPPLY OF COMPRESSED AIR AND HYDRAULIC PRESSURE............................9

9. FIBER CABLE BLOWING........................................................................................10

10. MAINTENANCE .......................................................................................................11

10.1. CHAIN MAINTENANCE AND ADJUSTMENT ................................................................ 11

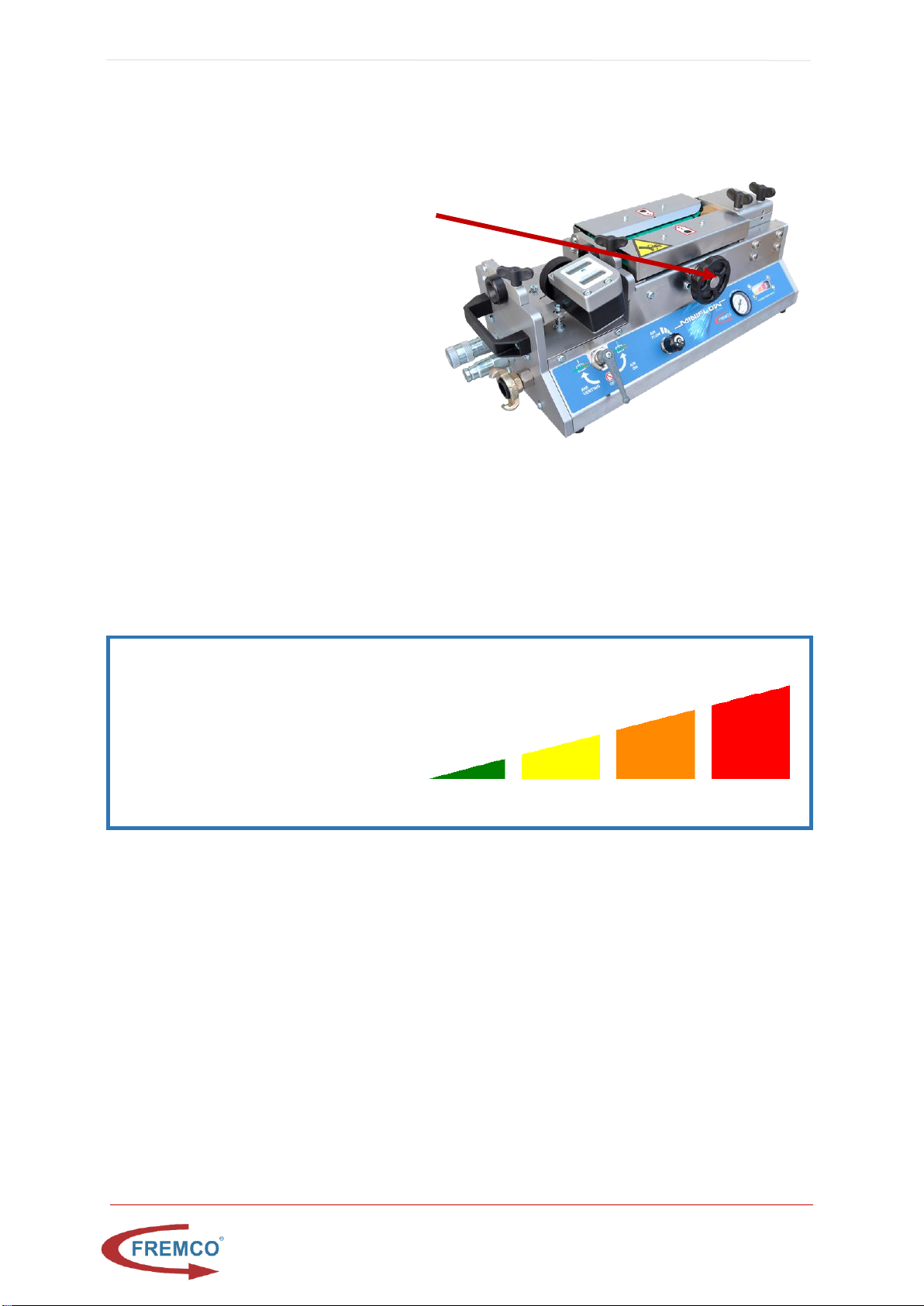

11. MACHINE OVERVIEW.............................................................................................13

12. OPERATION ............................................................................................................14

12.1. PREPARING OPERATION ............................................................................................. 15

12.2. DURING OPERATION .................................................................................................... 16

12.3. AFTER OPERATION....................................................................................................... 16

13. ADJUSTMENT OF PUSHING POWER INDICATOR (PPI).......................................17

14. CHANGING ADAPTOR PLATES.............................................................................18

15. CHANGING CHAINS AND CHAIN SUPPORT RAILS .............................................19

16. INITIAL ADJUSTMENT OF JOYSTICK....................................................................20

16.1. PREPARATION............................................................................................................... 20

16.2. ADJUSTMENT................................................................................................................. 21

17. OPERATING THE JOYSTICK..................................................................................23

17.1. IMPORTANT NOTE REGARDING POWER AND SPEED ADJUSTMENT.................... 25

18. EC DECLARATION OF CONFORMITY.........................................................................26

19. UKCA DECLARATION OF CONFORMITY....................................................................27