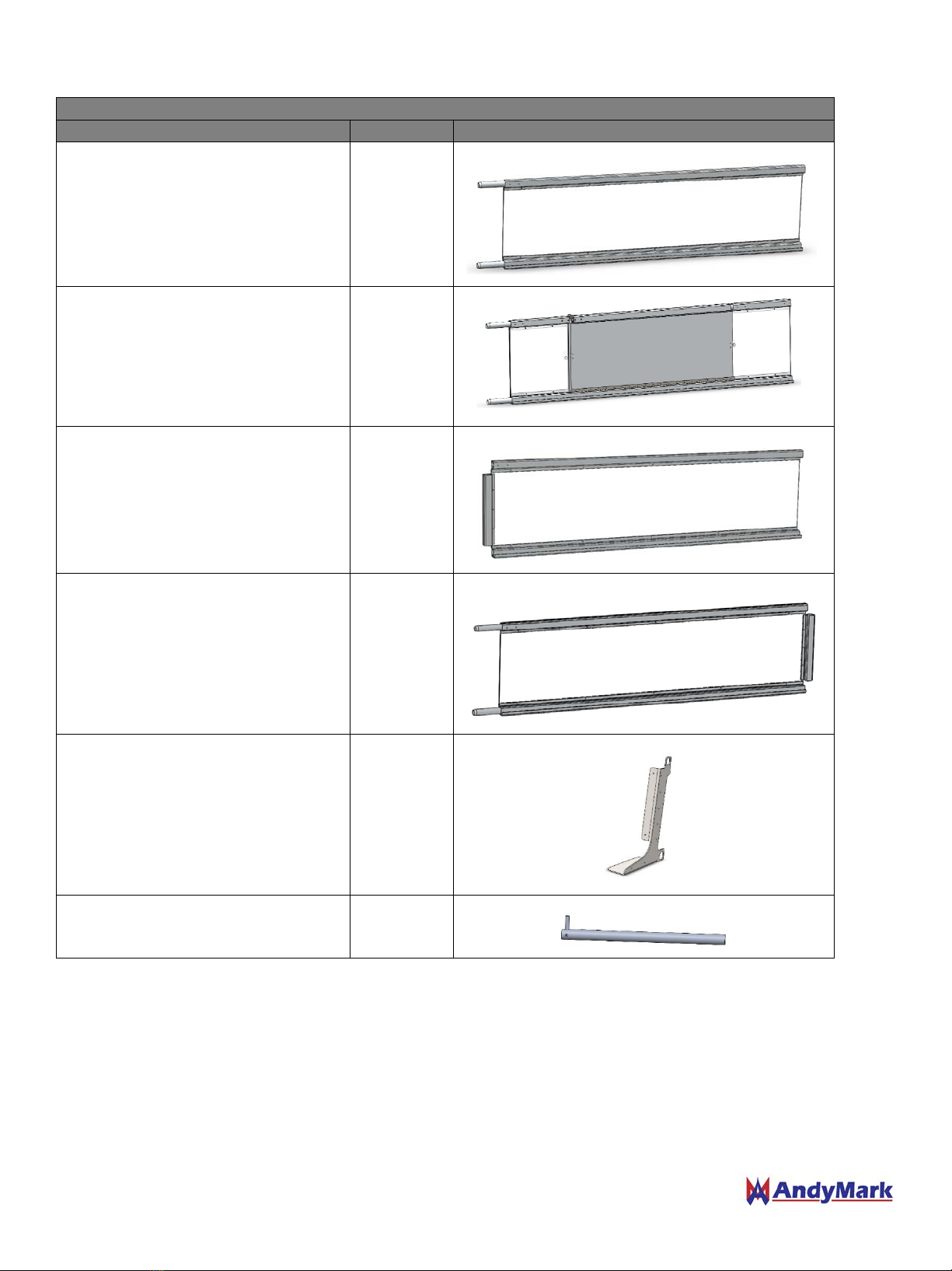

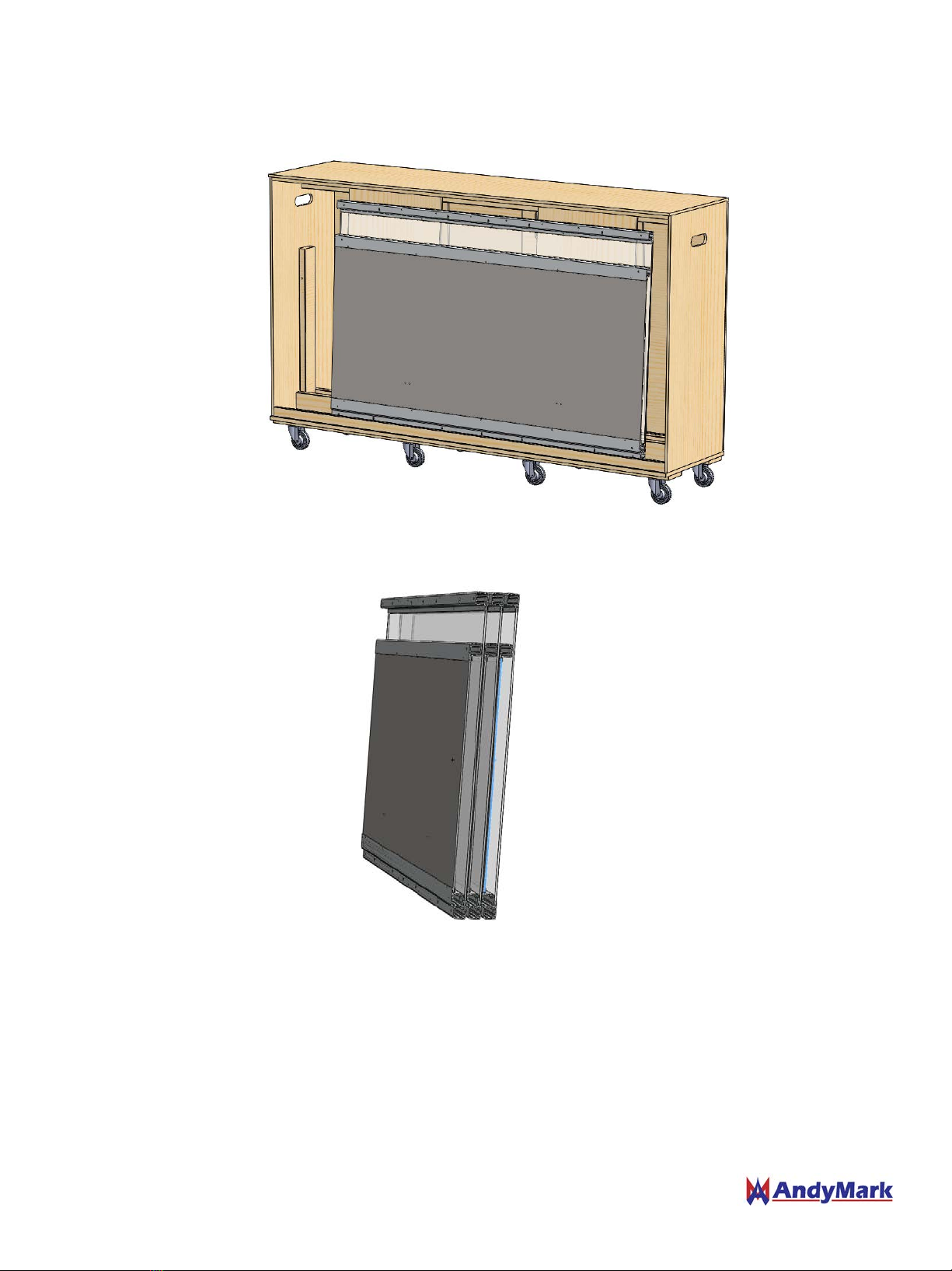

Side Rail Assembly

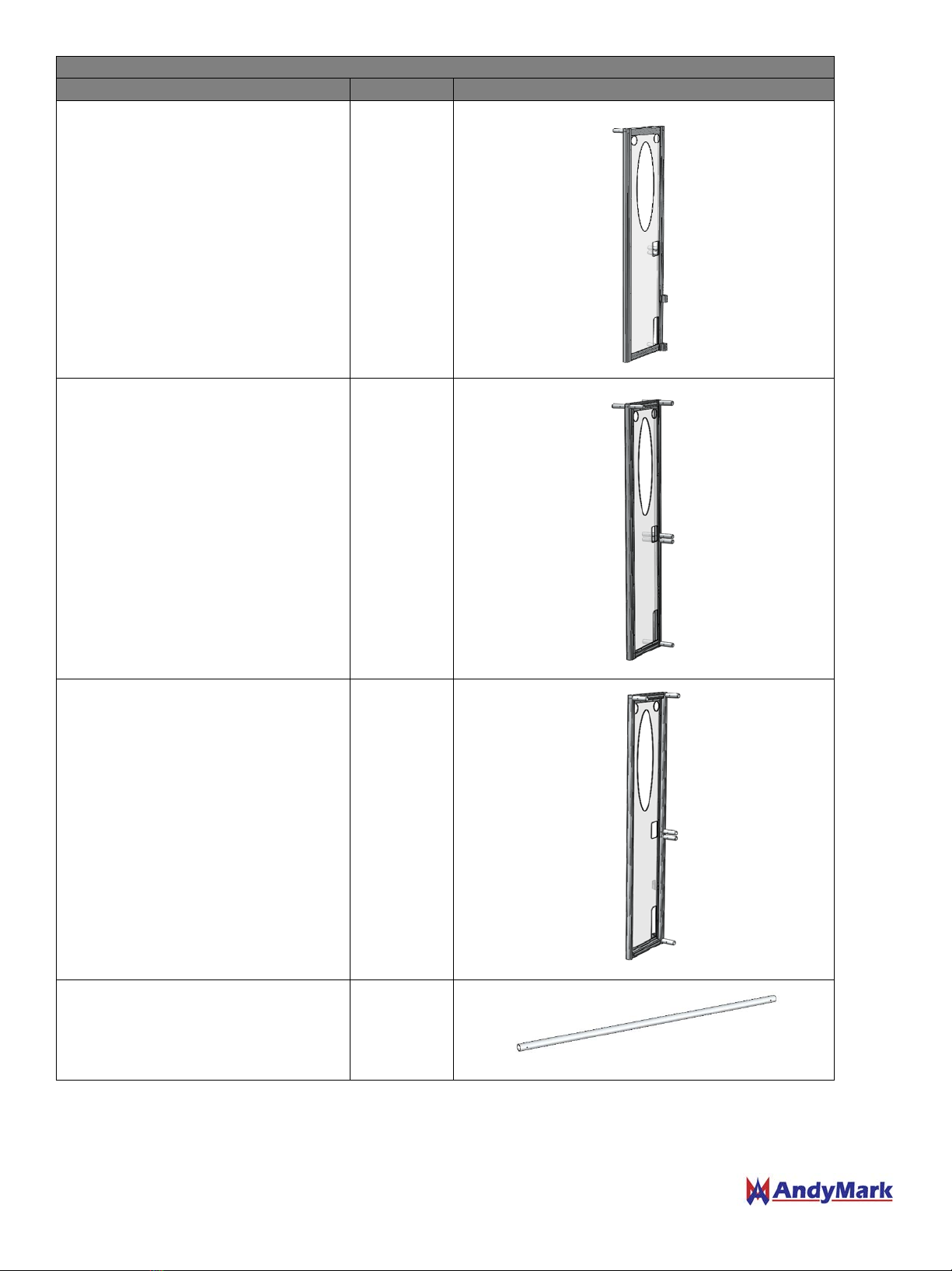

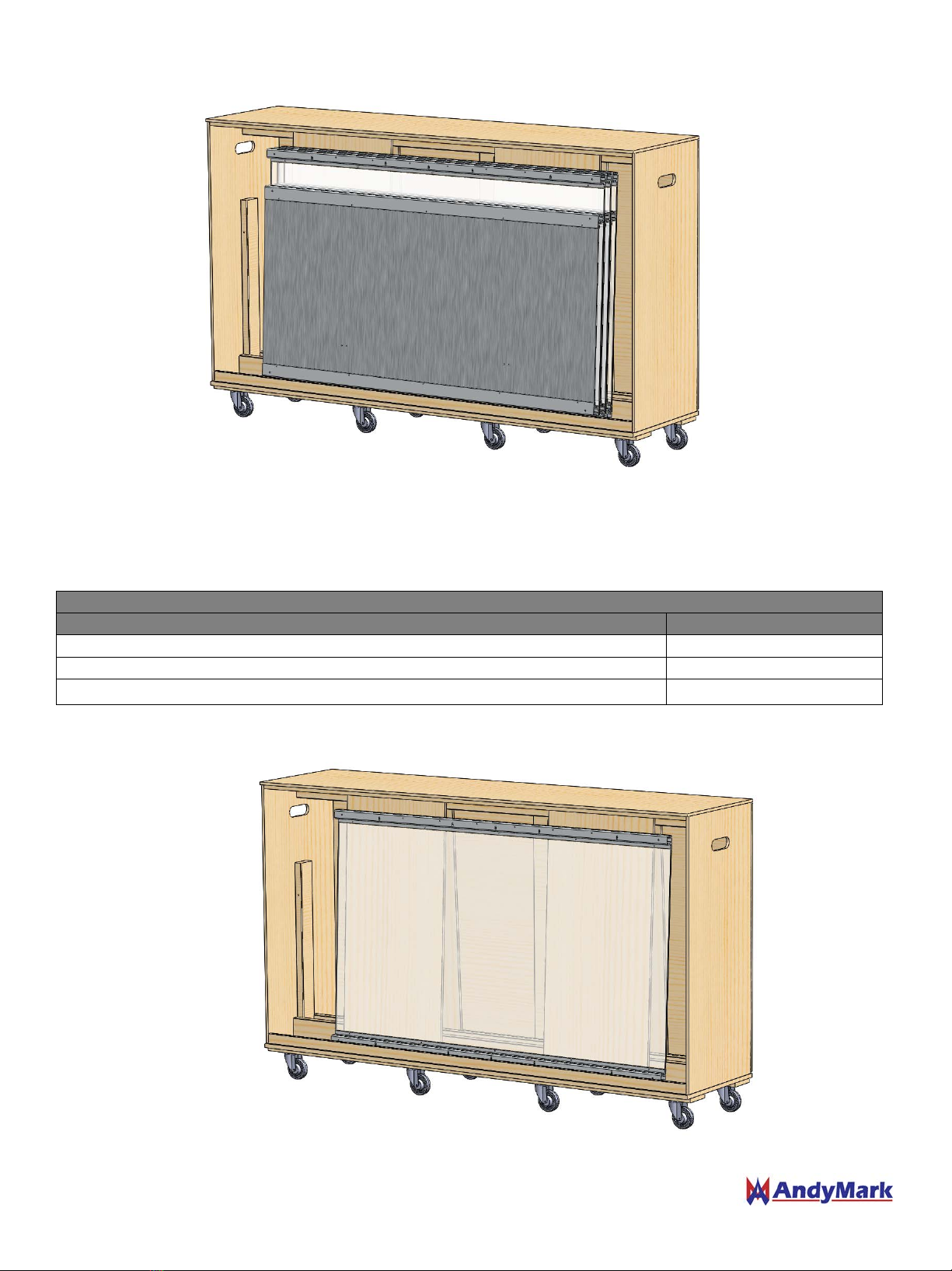

1. Lay out all Guardrail, Outrigger and Human Player Barrier segments. All of the side rail sections are identical

and the gates are identical. The side should be laid out in the following order. Pieces can be labeled for future

assembly.

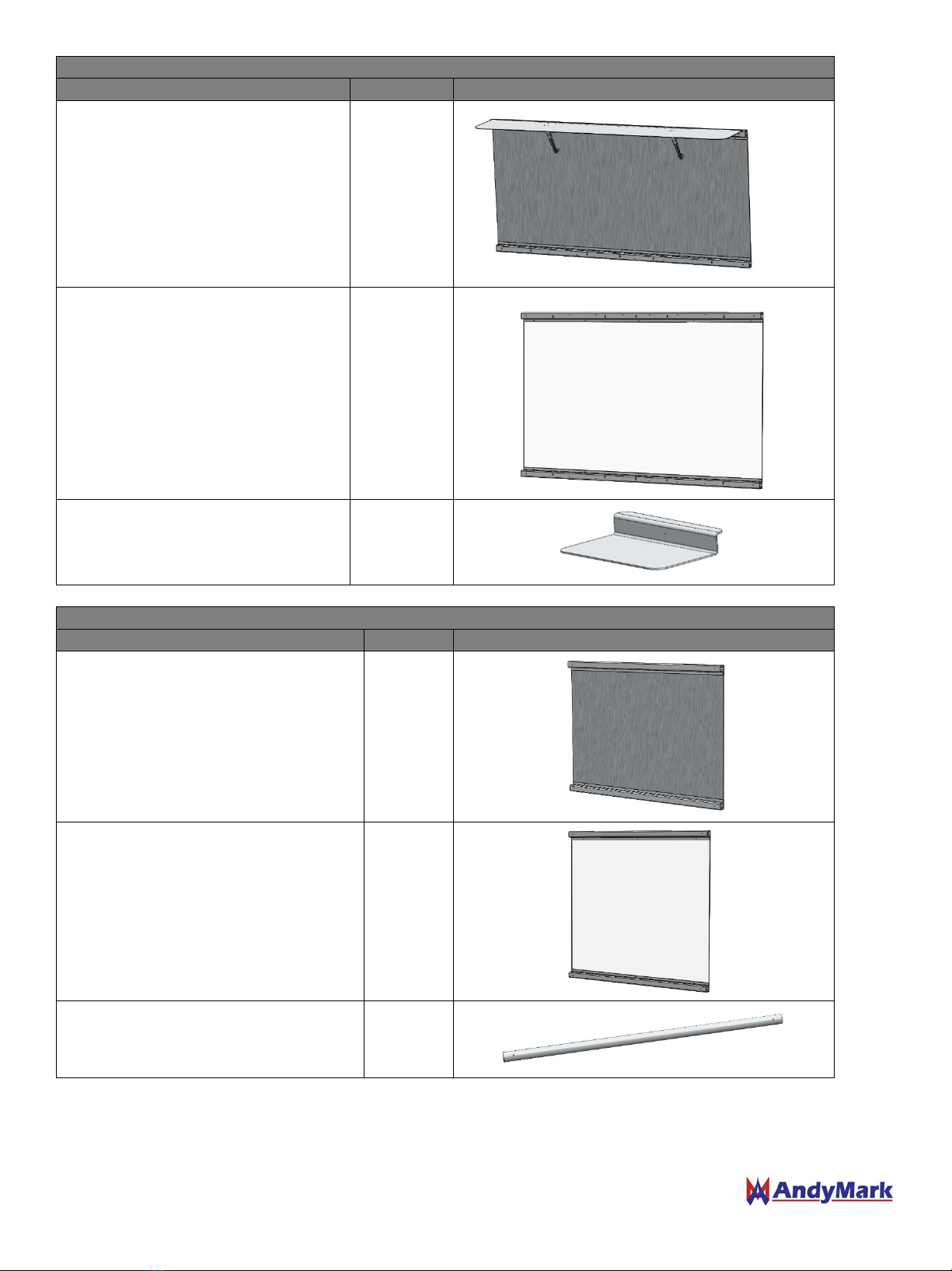

2. Connect the segments by inserting the smaller tube into the larger on the top and bottom rail. Be sure to

slide the Outriggers in between each panel section.

NOTE: The Velcro foot on the outrigger should be on the same side as the Velcro bottom of the side rail. The

flat edge of the panel will face the inside of the field.

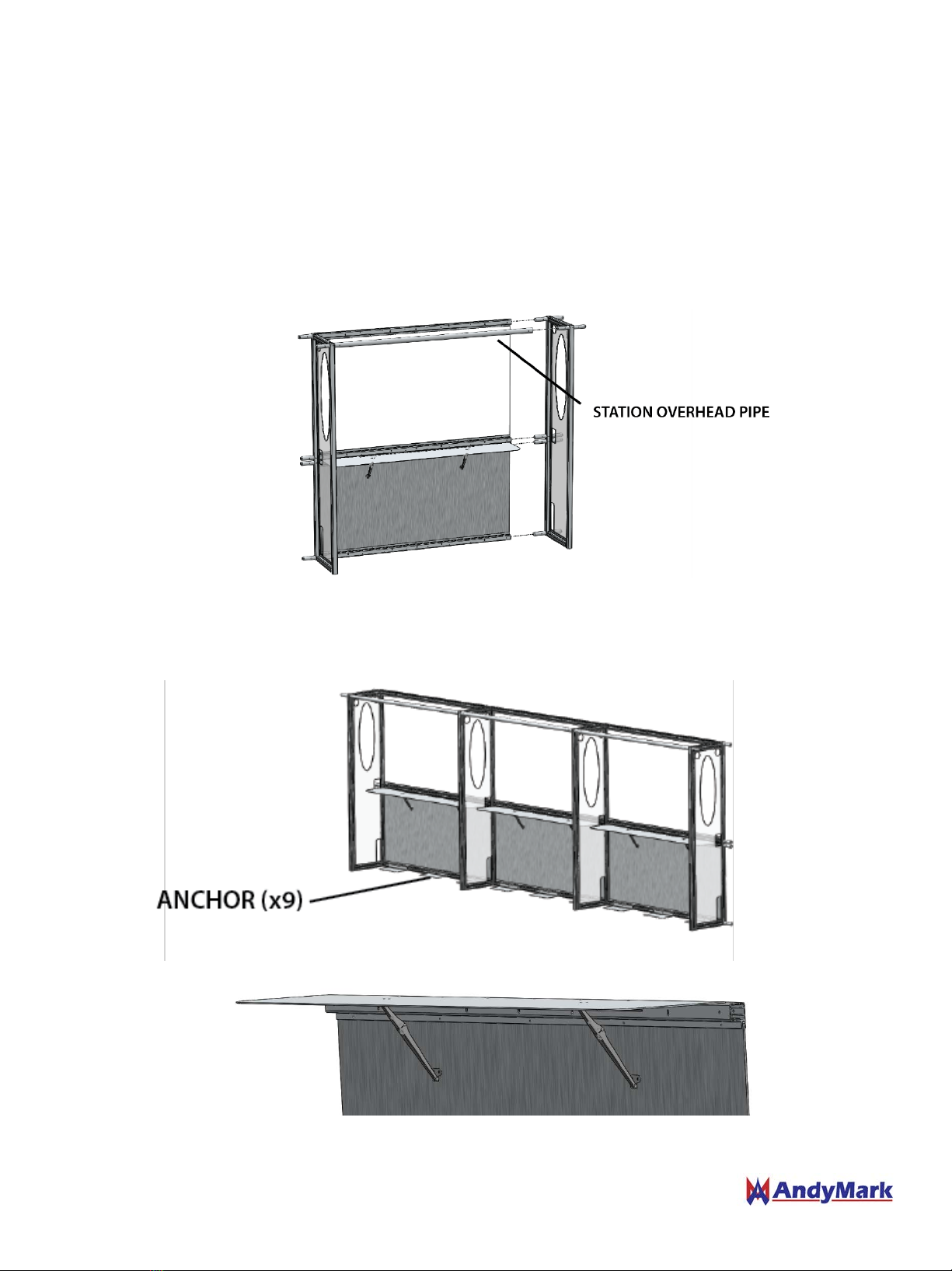

For 2014 also be sure to slide the Human Player Barrier Brackets and Poles on as well

NOTE: There are two HP barrier poles per side that are longer in length than the others. Those go on each end.

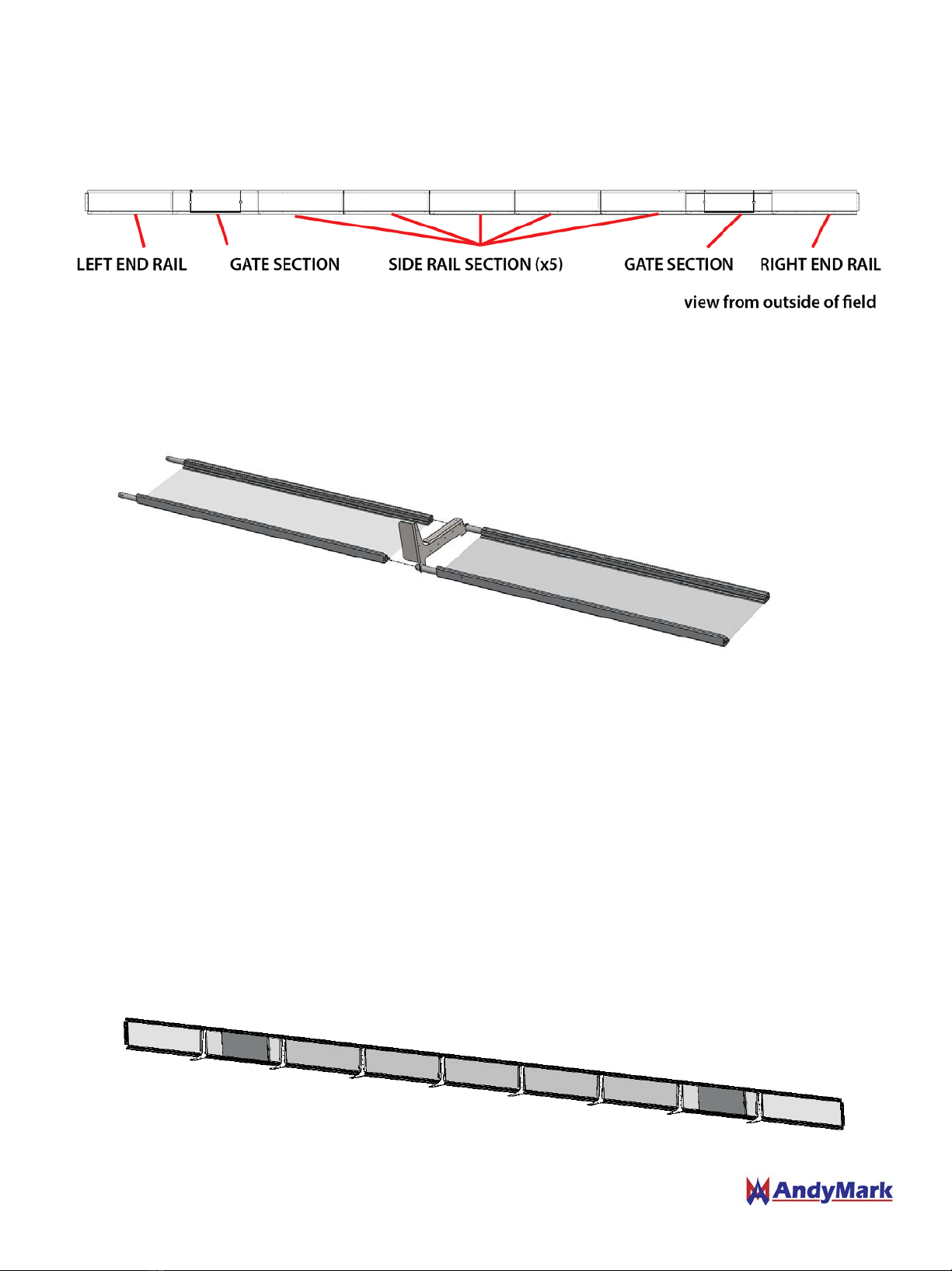

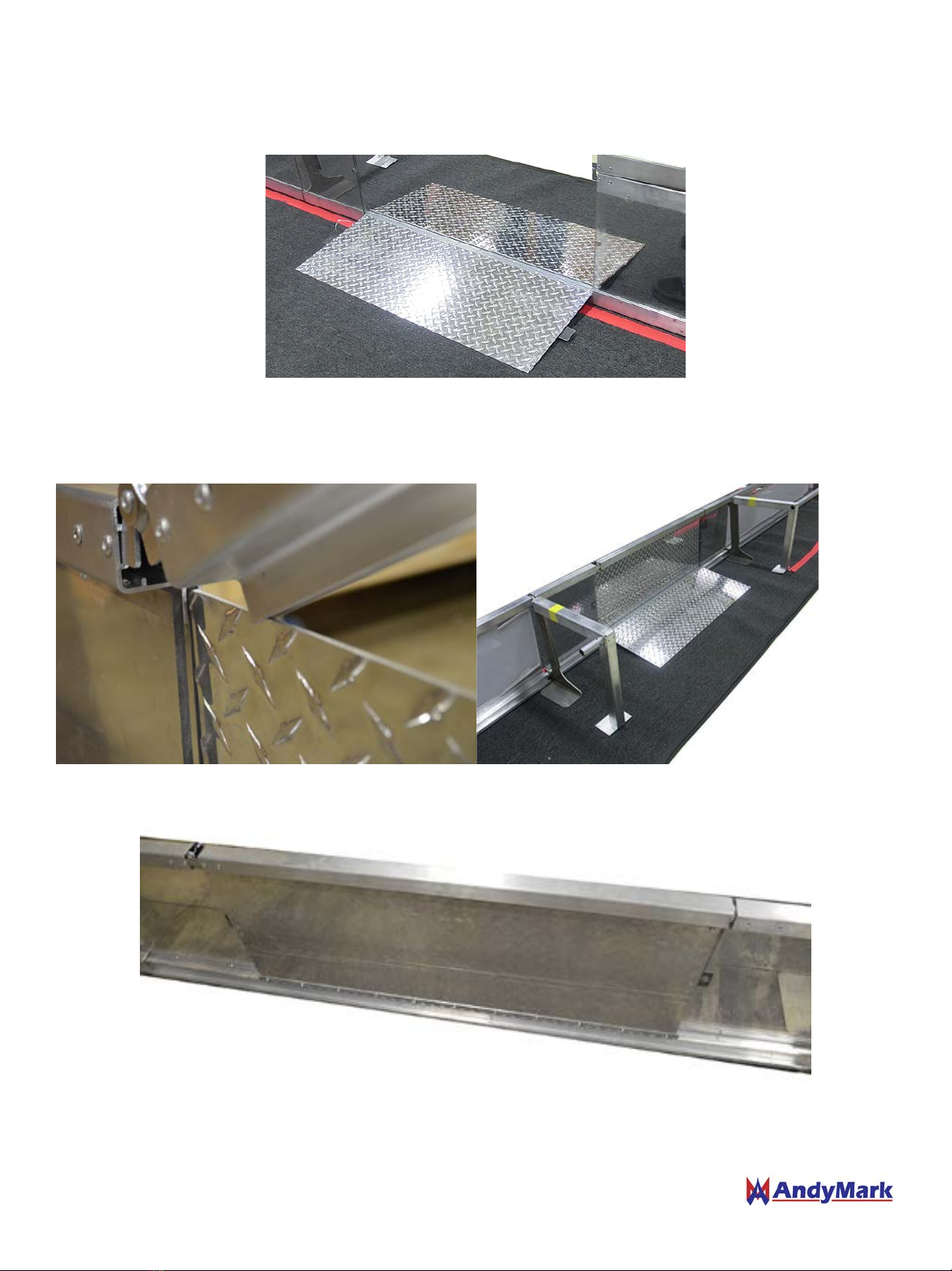

3. Align the edge of the bottom Velcro angle with the measured line for the side border edge

4. Align the end of the panel row with one measured end line on the field

5. Ensure there are no gaps between the panels

6. Use four (4) or more people to flip the entire Side Border assembly simultaneously into the upright position.

The crew should be positioned on the inside of the Field. Make sure the inside bottom line remains located on

the respective chalk line.

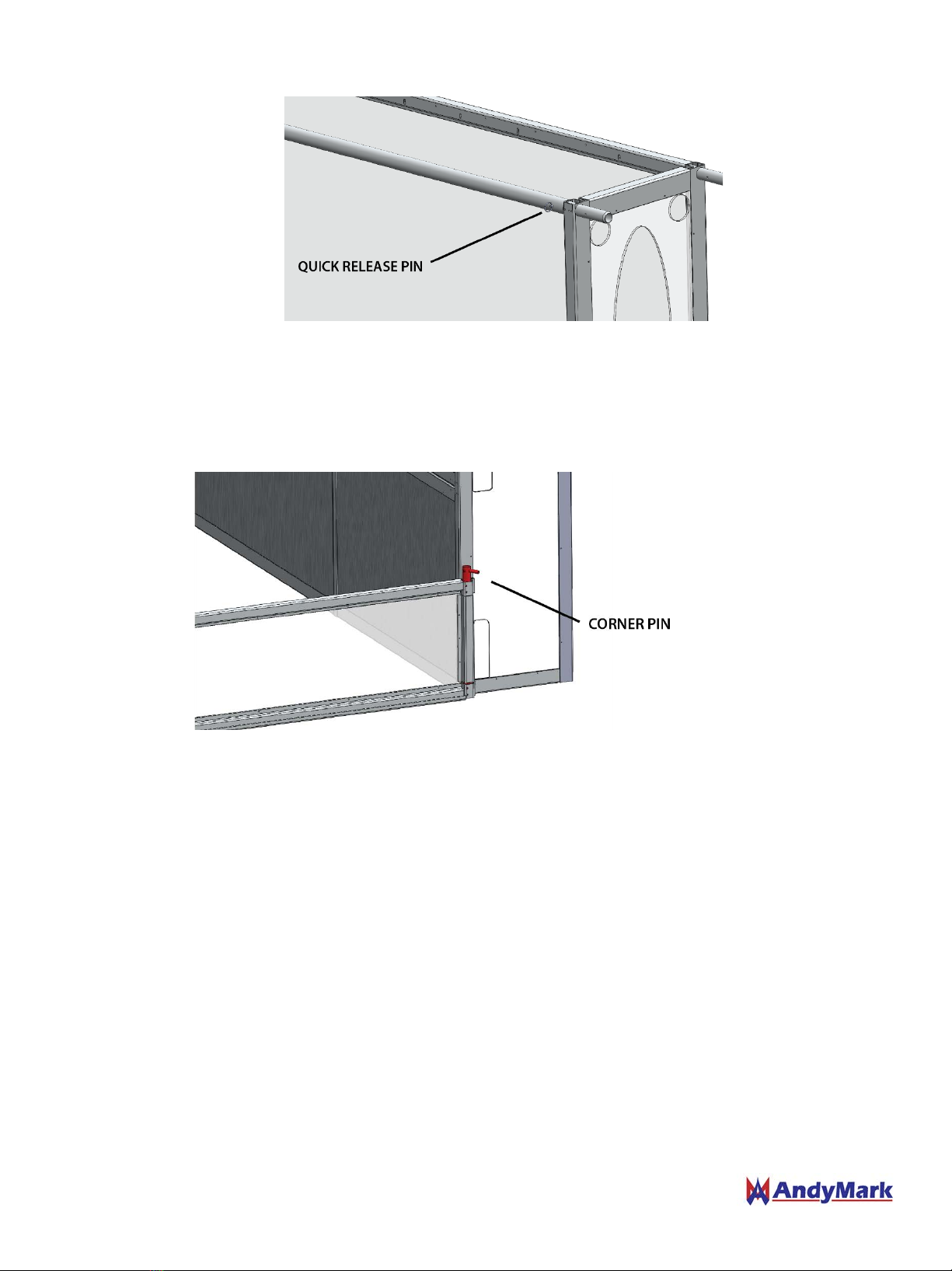

For 2014, when the Field Border is in the correct position, flip the Human Player Barrier to the outside of the

Field. Be sure to pin the poles of the Human Player Barrier into position after it is in place.

Rev 1.2 10/23/14 5