4

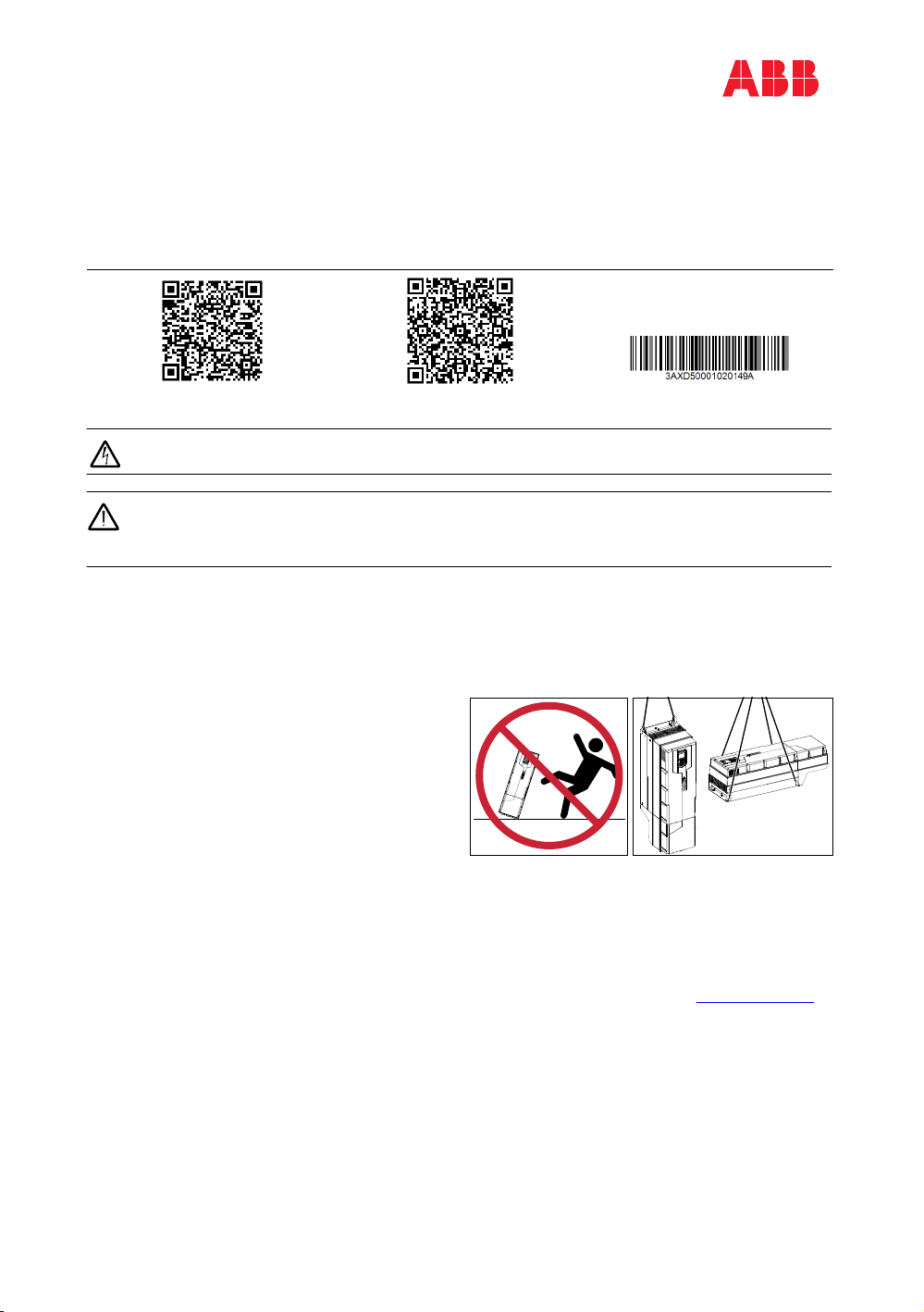

10. Measure the insulation resistance of the power cables and the motor

Measure the insulation resistance of the input cable before you connect it to the

drive. Obey local regulations.

Measure the insulation resistance of the motor cable and motor when the cable

is disconnected from the drive. Measure the insulation resistance between each

phase conductor and the PE conductor. Use a measuring voltage of 1000 V DC.

The insulation resistance of an ABB motor must be more than 100 Mohm

(reference value at 25 °C or 77 °F). For the insulation resistance of other motors,

see the manufacturer’s instructions. Moisture inside the motor decreases the

insulation resistance. If you think that there is moisture, dry the motor and do

the measurement again.

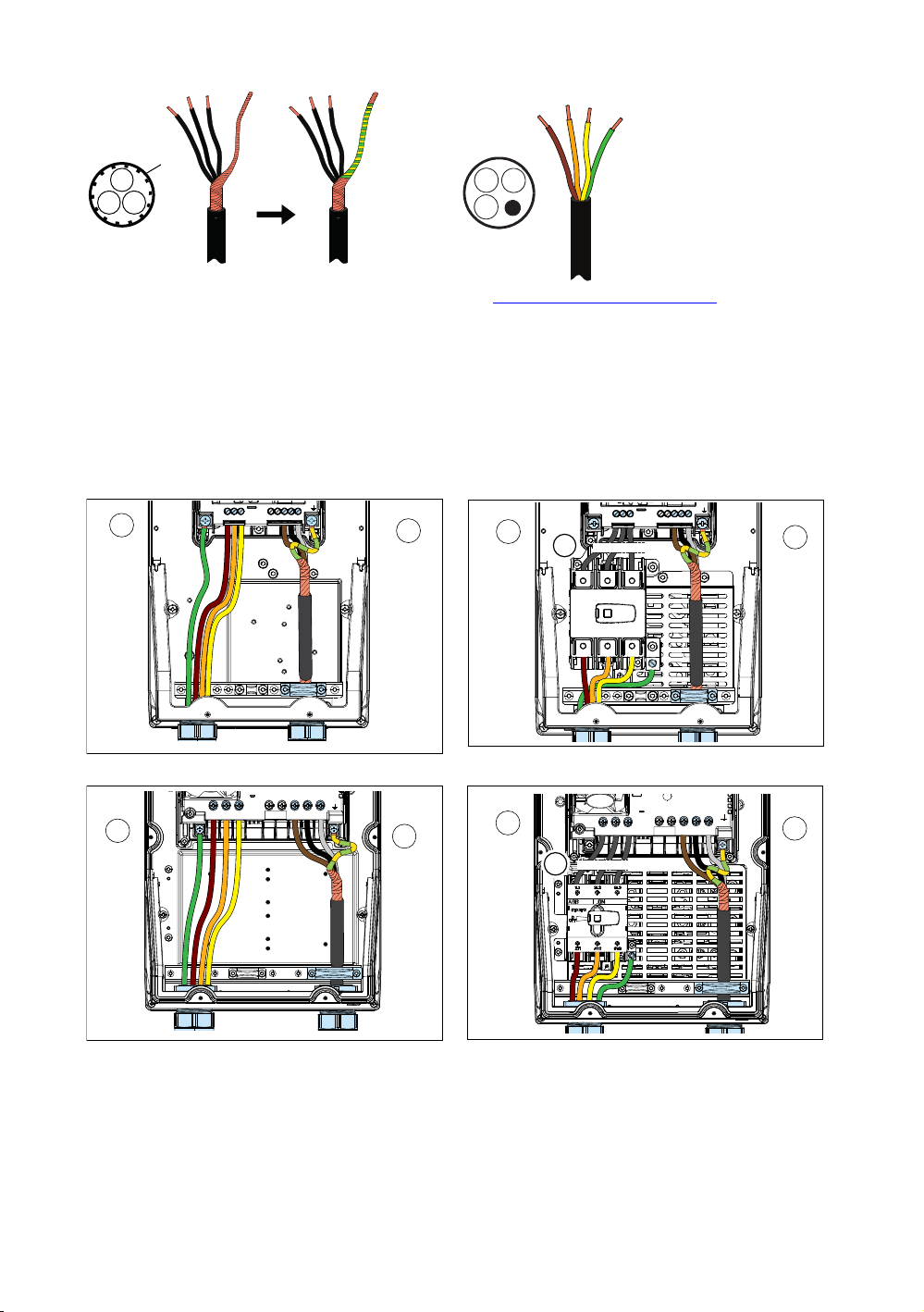

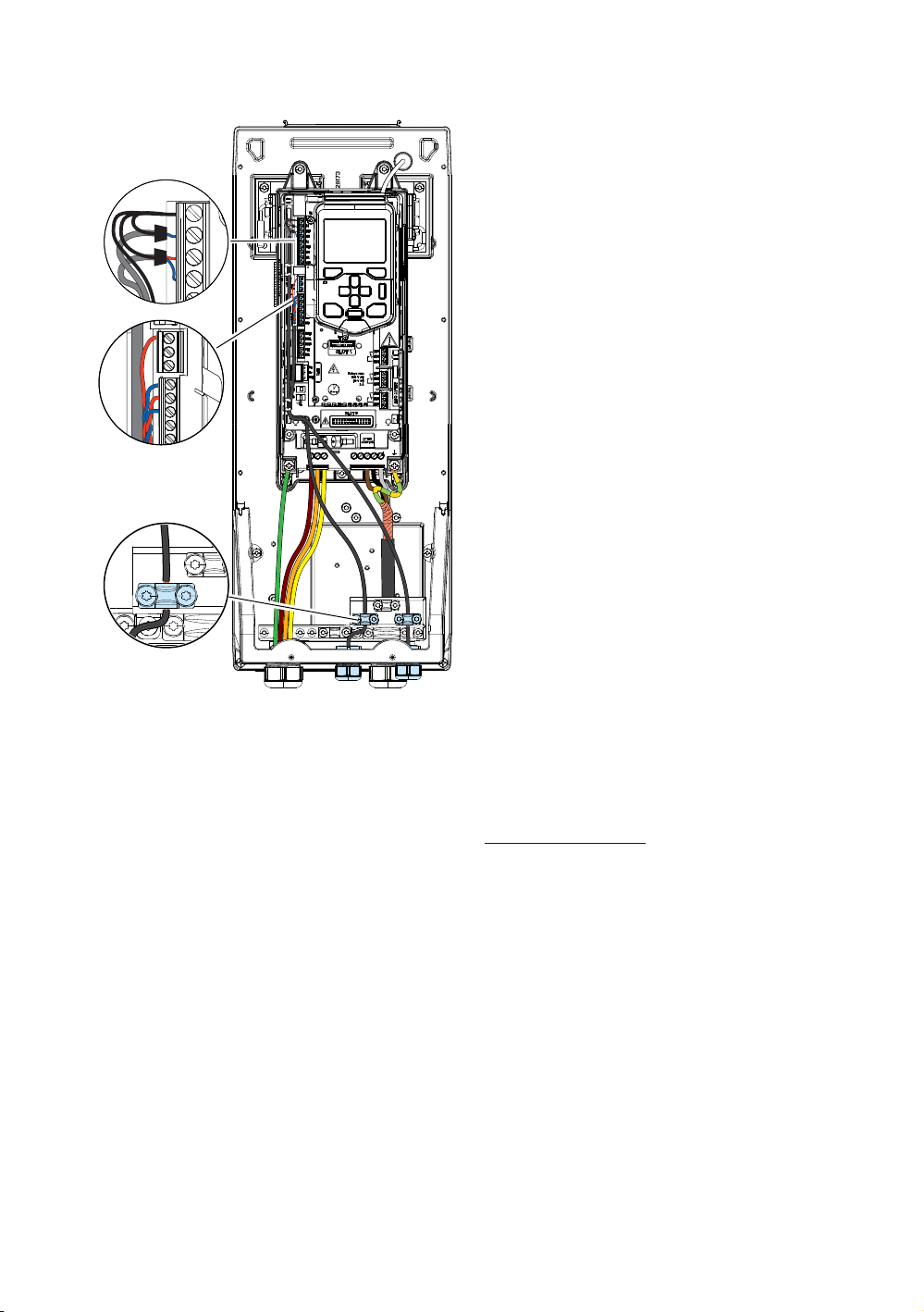

11. Connect the power cables

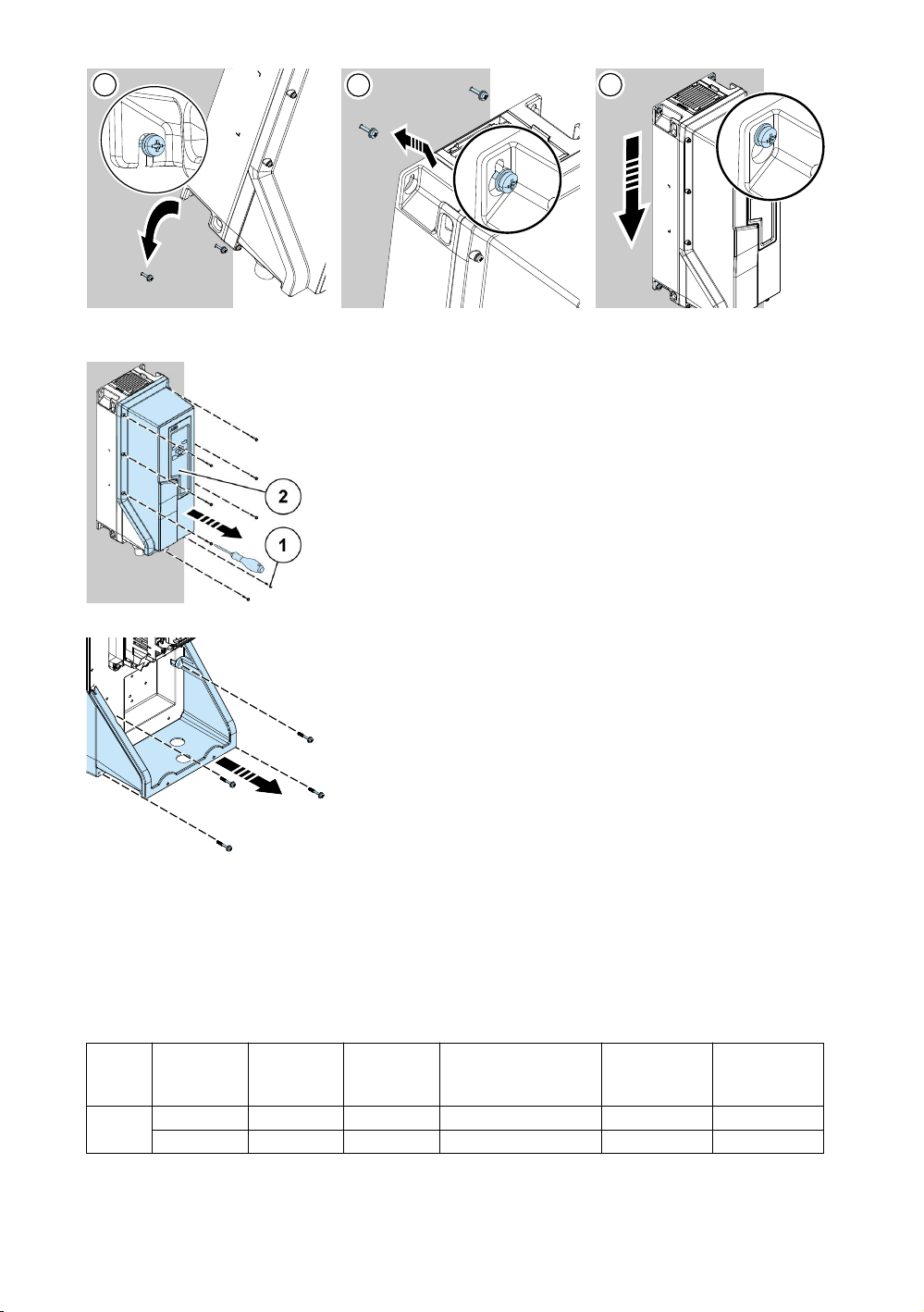

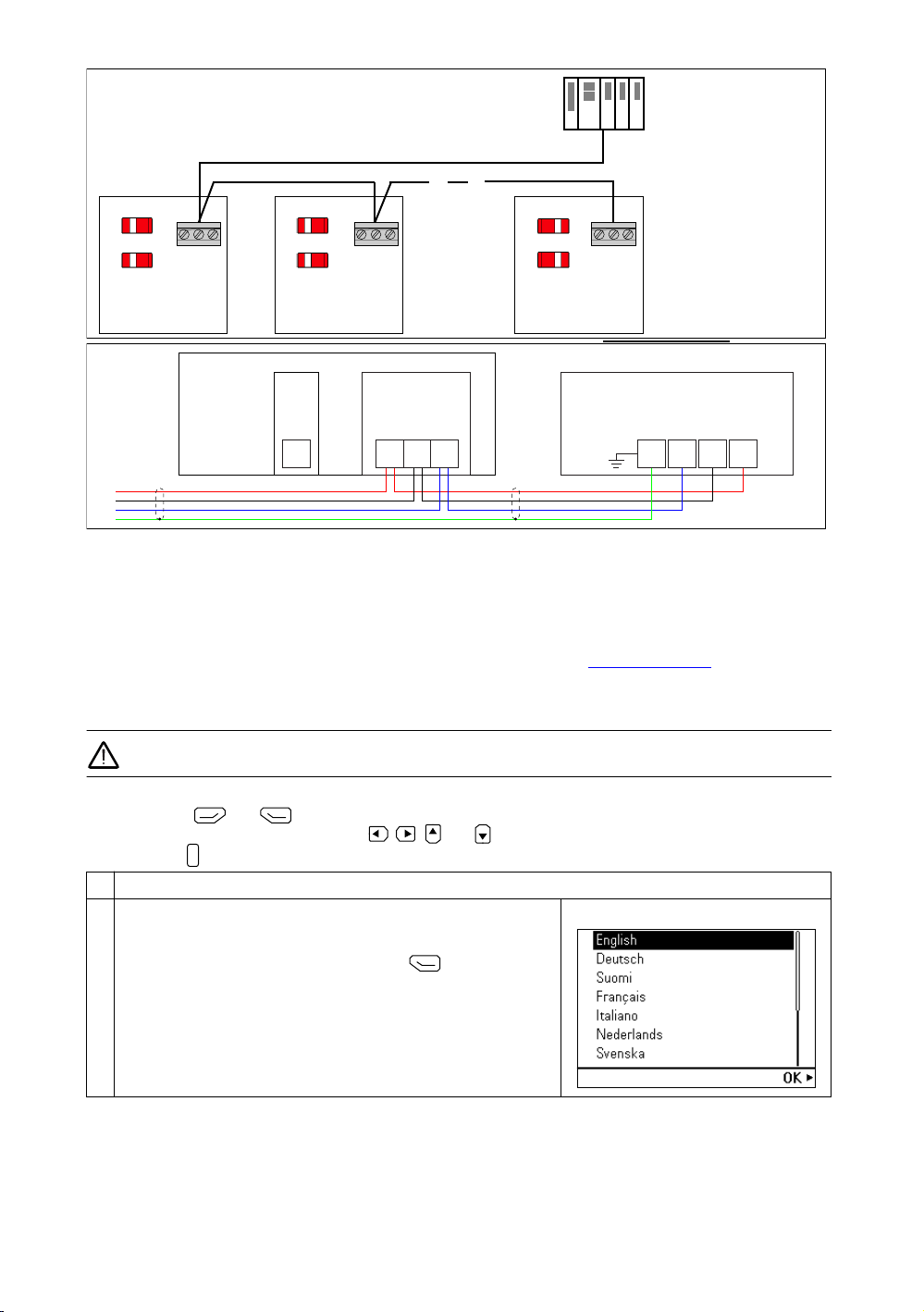

UL (NEC) connection diagram with symmetrically shielded cable or conduit

Connection procedure

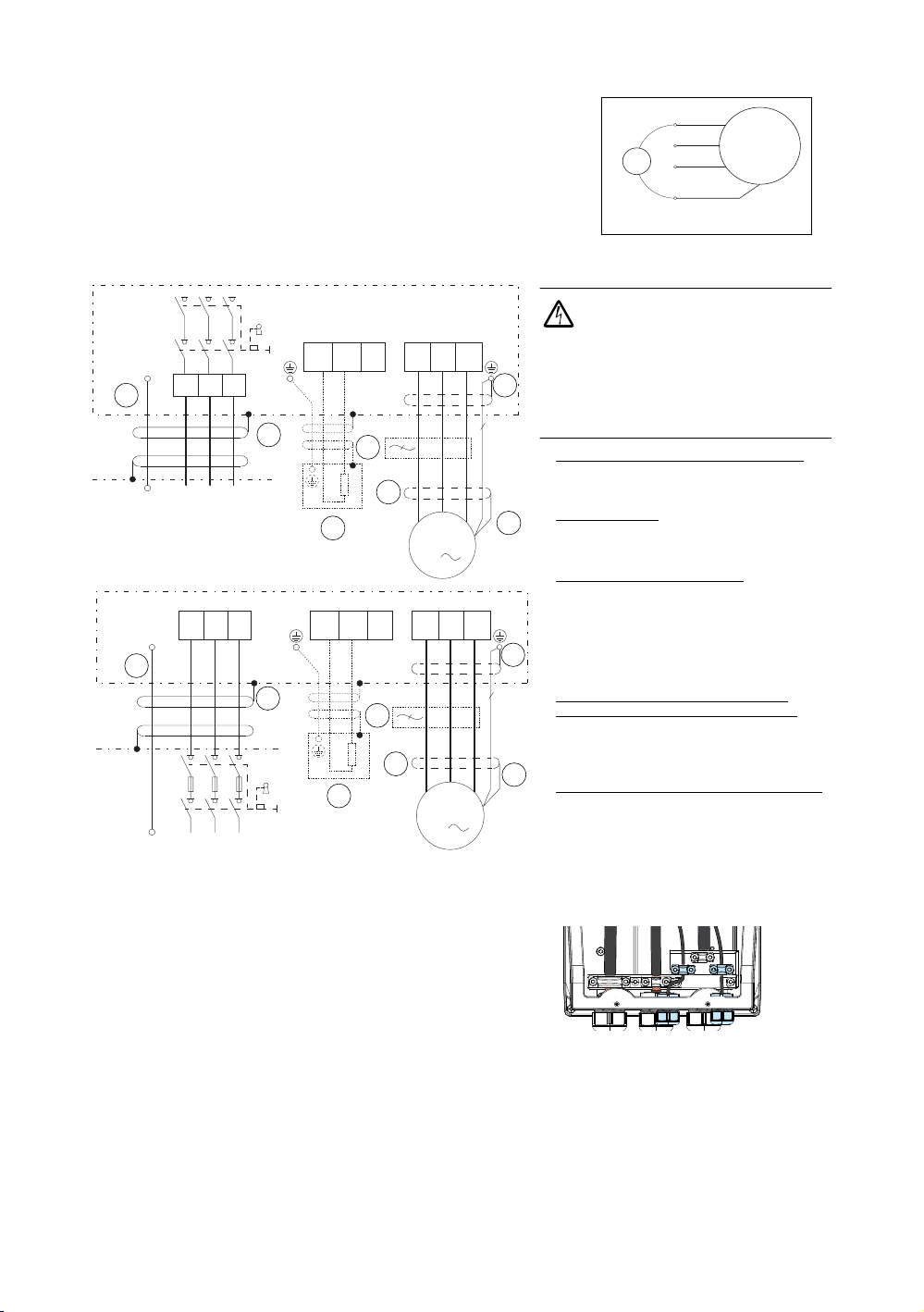

1. Prepare the power cables (shielded cable).

•Prepare the ends of the input power cable and motor cable as illustrated in the applicable figure (b).

•Install the conduit fitting or cord grip (not supplied).

•Slide the cables through the fitting or grip. After wires are terminated, complete installation of conduit and/or

tighten the cord grip to achieve a water-tight seal.

U1-PE, V1-PE, W1-PE

WARNING: If installing drive indoors or

outdoors in a wet, dirty, dusty,

corrosive or similar environment, all

cable, conduit and fittings must be approved

for use in this type of environment. Fittings

must be properly tightened to the drive such

that no leakage occurs. Failure to follow these

instructions can lead to injury or death, or

damage to the equipment.

a. Insulated ground conductor in a conduit:

Ground to drive's PE terminal and to the

distribution panel ground bus. For a VFD

cable installation see d.

b. Conduit ground: Bond the conduit to the

drive's conduit box and to the distribution

panel enclosure. For a VFD cable installation

see c.

c. Shield of a VFD shielded cable: Ground the

shield 360° under drive's grounding clamp,

then twist with the ground conductors and

connect under the drive's ground terminal.

Ground the shield also 360° at the motor end,

then twist and connect under the motor's

ground terminal. For a conduit installation

see b.

d. Symmetrically constructed grounding

conductors inside a VFD shielded cable:

Twist together, combine with the shield and

connect under the drive's ground terminal

and under the motor's ground terminal. For a

conduit installation see a.

e. External brake resistor connection (if used):

For a conduit installation see a and b. For a

VFD cable installation see c and d. In

addition, cut the third phase conductor

which is not needed for the brake resistor

connection.

f. If necessary, install an external filter (du/dt,

common mode, or sine filter). Filters are

available from ABB.

Note: UL (NEC) installation can include separate insulated conductors

inside a conduit, shielded VFD cable in conduit, or shielded VFD cable

without conduit. The normal dashed symbol (c) in this diagram

represents the shield of shielded VFD cable. The same solid symbol (b)

represents conduit.

PE

PE

L1 L2 L3 R-

U1 W1

M

3

T1/U T2/V T3/W

V1

L1 L2 L3

PE

3

UDC-

R+

UDC+

a

b

cd

d

e

f

PE

PE

2T1 4T2 6T3

L1 L2 L3

R-

U1 W1

M

3

T1/U T2/V T3/W

V1

PE

3

UDC-

R+

UDC+

Drive with disconnect option

Drive without disconnect option

a

b

c

d

e

f

d

Grounding clamps