LAUNCH TLT830WA INSTALLATION MANUAL

Notice

:

All the dimensions take the external boundary of

the floor plate as the datum.

Ensure that the overall errors shall be controlled

within 6mm(0.24″).

The line layout is very important. If not correct,

problems will happen during the final assembly

and operation.

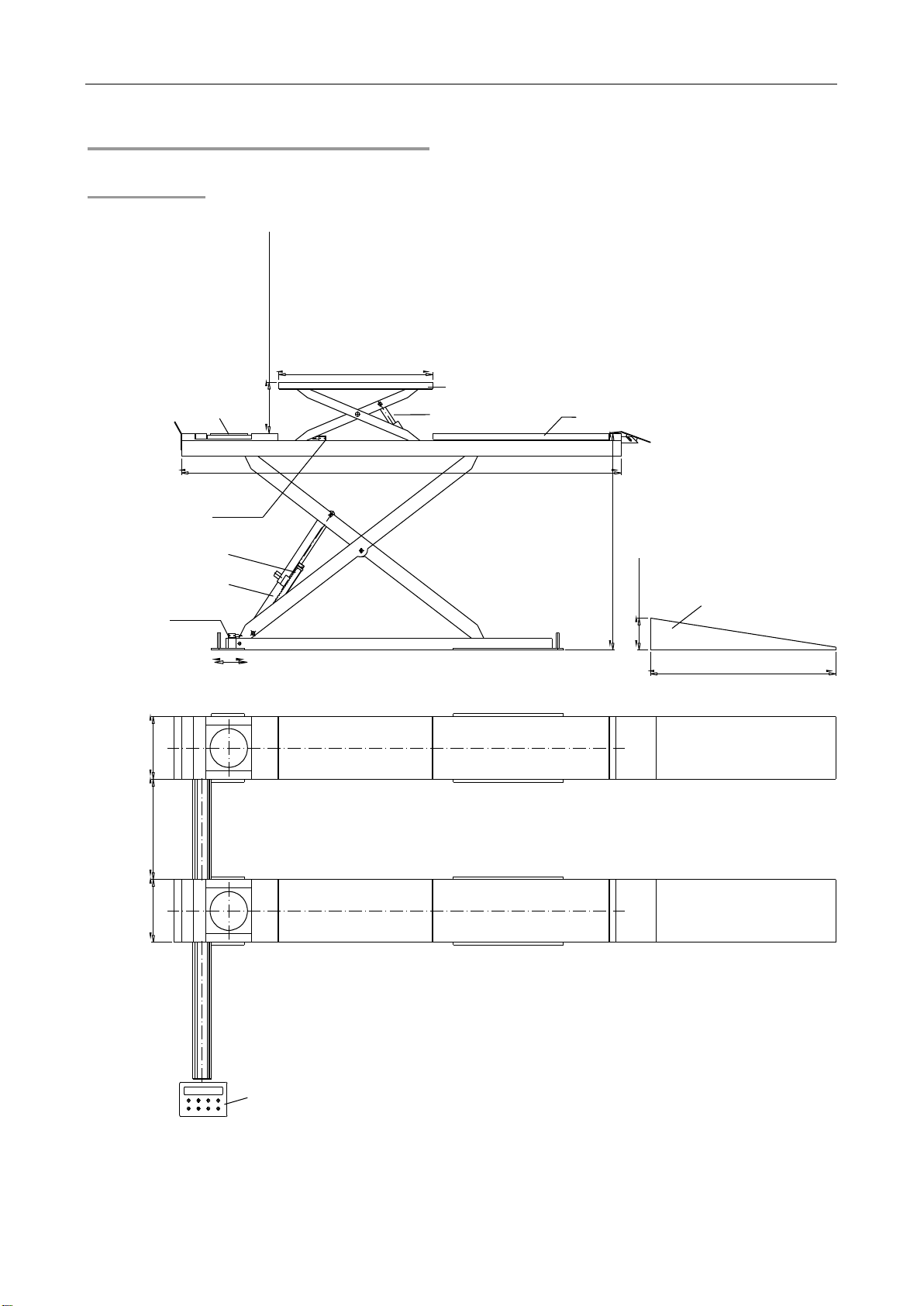

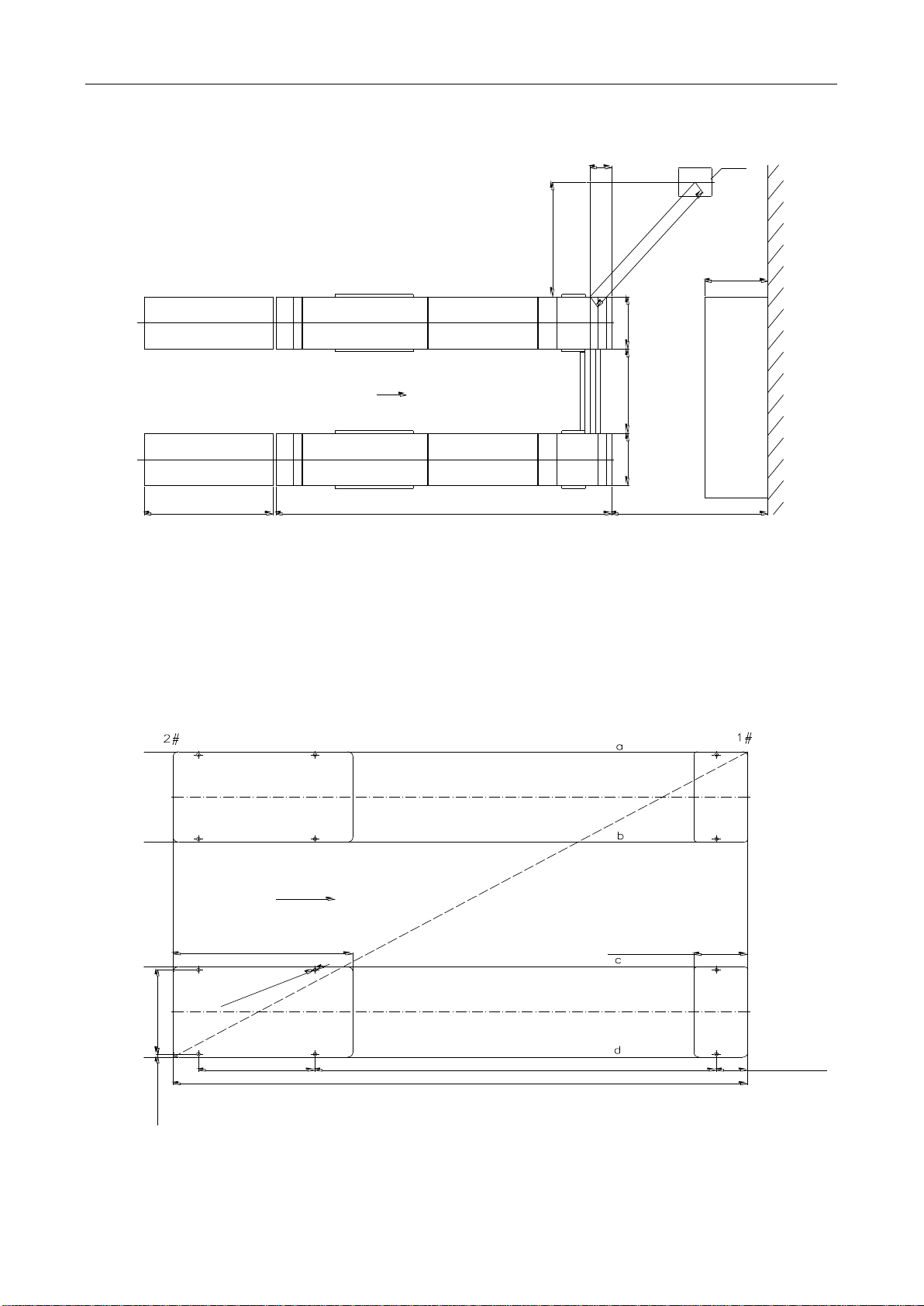

5.3 Installation on Ditch

The layout for ditch installation is similar as for ground

installation, but it is more difficult. The dimension of the ditch

channel can be seen in Fig. 8.

Notice

:

The thickness of the concrete slab is not less than

200mm. The basic intensity of the concrete slab

should reach above 3000PSI

(

2.1kgf/mm2

)

.

Lifting jack should be used to place the master

and slave units in to the ditches.

Fig.8

5.4Control Desk Installation

Select the installation site for the control desk

according to the layout.( Fig. 6)

Install the cover plate for the hoses and cables if the lift

is installed on the ground.

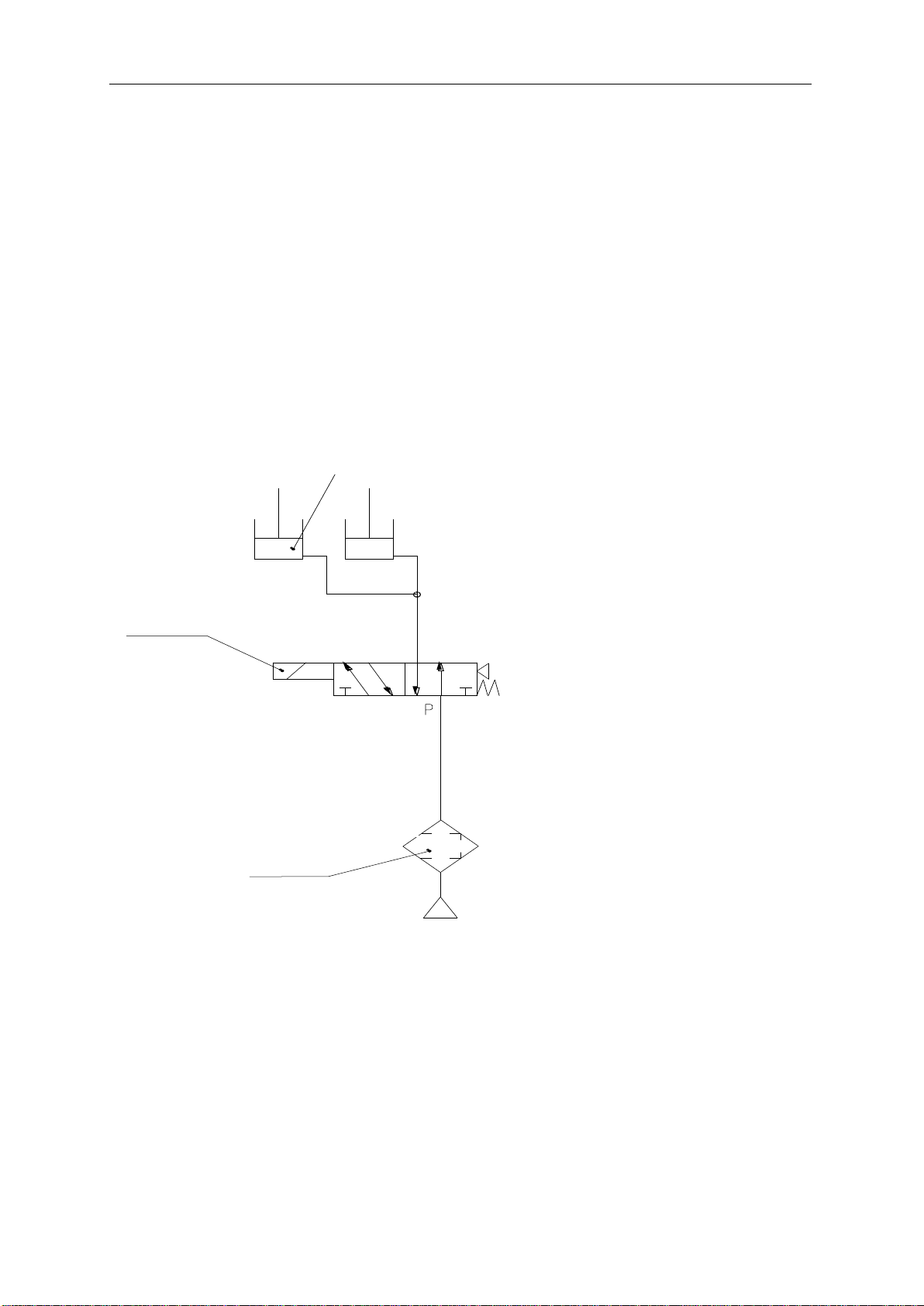

Fill the hydraulic oil to the oil tank with a proper quantity.

Do it carefully to prevent the dust or other pollution get

to the oil.

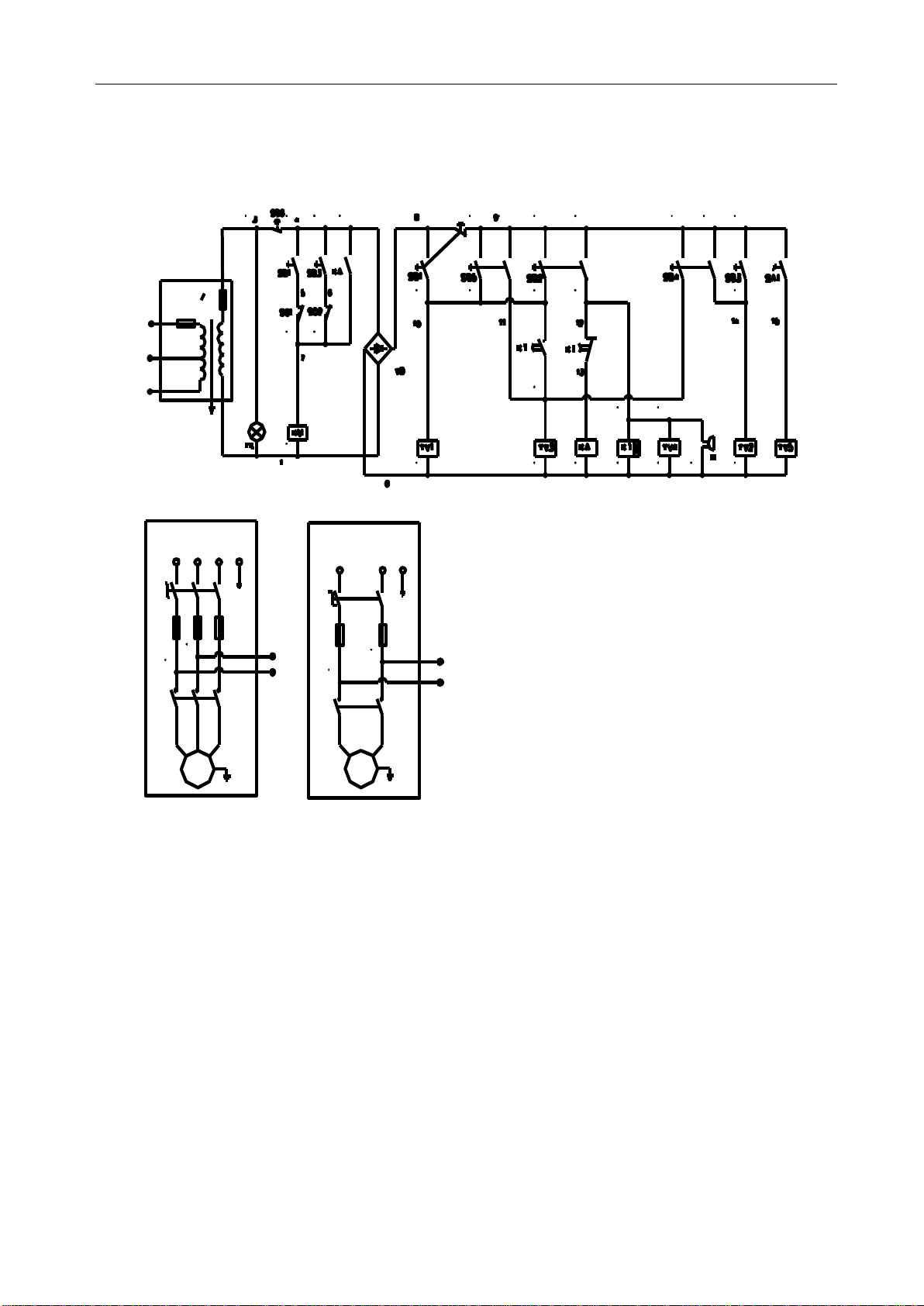

5.5 Power connection

Open the door at the back of control desk. Connect the

limit switch 1 cables on terminal 5, 7 and limit switch 2

on terminal 6, 7. Then connect power input cable to

terminal L1, L2, L3, PE (see Fig.9). The power indicator

on the operation panel should light on when the power

is on.

Fill hydraulic oil N32 or N46 into the oil tank (using oil

gauge to check the level). Pay special attention to

avoid dust and contaminants into the oil.

Note: High Voltage inside the control desk! Wiring

should be performed carefull

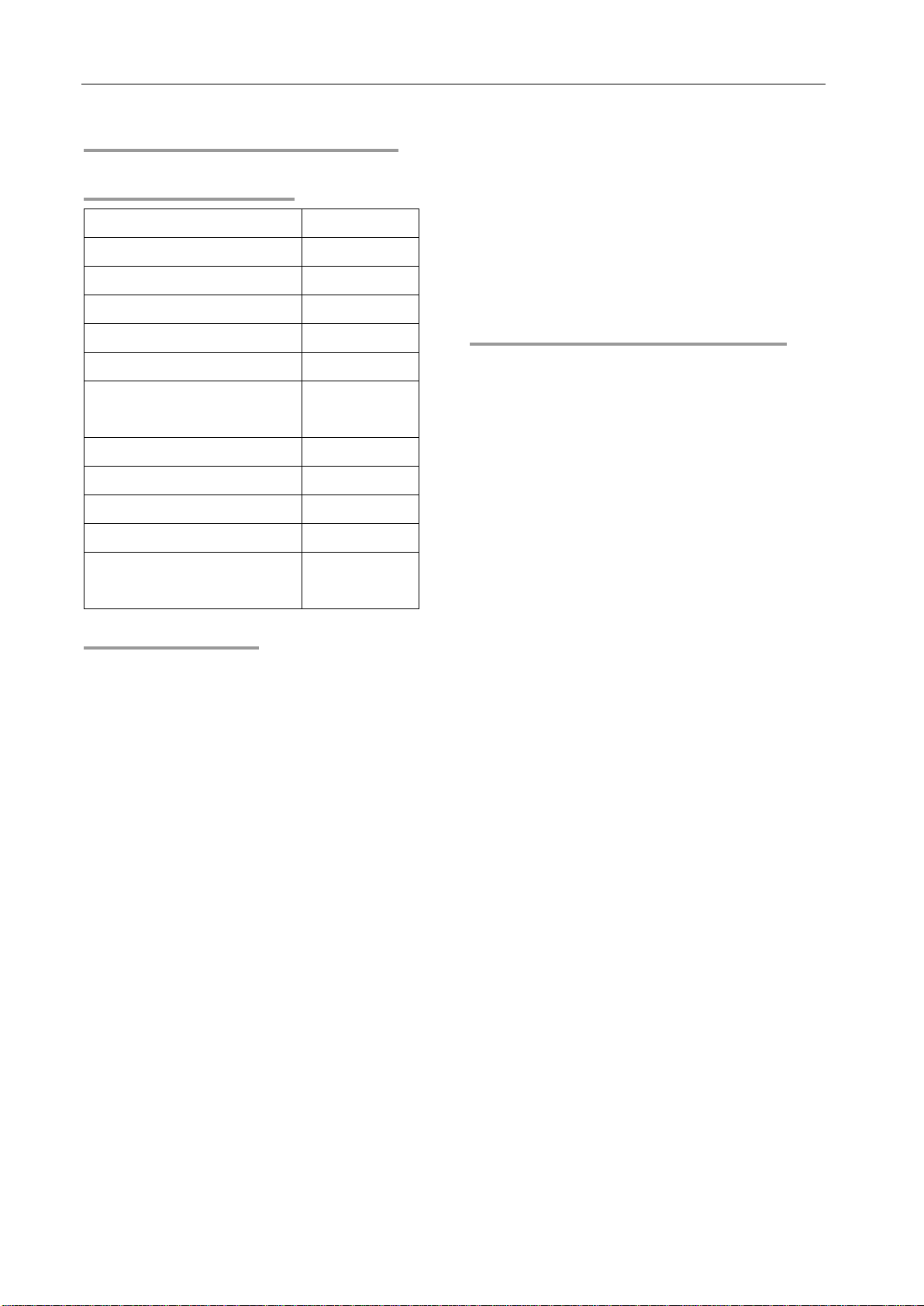

Slave Unit

Drive-On

Master Unit

min 2000mm(78.7″)

Floor

max 1800mm(70.9″)

min 1200mm(47.2″)

630mm(24.8″)800mm(31.5″)

800mm(31.5″)

Control Desk

630mm(24.8″)

Wheel Alignment

Pre-buried Pipe 100mm(3.9″)

4080mm(160.6″)

320mm(12.6″)

340mm(13.4″)

150mm(5.9″)

100mm(3.9″)