Lavo Solutions MiniWash 100 User manual

Rev B 92818 Page | 1

MiniWash 100

INSTRUCTION MANUAL

Rev B 92818 Page | 2

TABLE OF CONTENTS

Introducon/Safety/Tech Specs 2

Quick Start Guide 3

Troubleshoong / Other Features 4

Priming/Default Sengs 4

Terms & Condions 5

Introduction

The MiniWash series is a simple solution for dispensing a single formula at up to 8 oz/min. The dispenser can be trig-

gered with a signal or with an optional push button switch, which can be mounted up to eight feet away. The pump

comes with a standard EPDM squeeze tube and can be used in a wide array of dosing applications.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN PERSONAL INJURY OR DAMAGE TO

THE EQUIPMENT LEADING TO IMPROPER OPERATION OR PRODUCT FAILURE. DEFECTS FROM A LACK

OF ADHERENCE TO THESE INSTRUCTIONS ARE NOT WARRANTABLE

IMPORTANT: DISCONNECT ALL POWER PRIOR TO SETTING UP THIS DISPENSER.

Safety

Function Specification

Power Connection (Cable 1) 100-240 VAC

Signal Connection (Cable 2) 20-240VAC (LO or HI)

Power Consumption 5W

Fuses 400mA 250VAC

Pump Flow Rate 8 oz/min

Max Suction Height 5 feet

Power the pump using cable 1 with the plug. When this unit is powered, the pump is ON. Connect cable 2, identified by

the word SIGNAL to the washer signal. Proceed with programming as shown in this manual.

Technical Specification

Rev B 92818 Page | 3

MiniWash 100—Quick Start Guide

Changing access code

• Enter the programming mode.

• Press the ▲ key until the display shows “o+old access

code”.

• Press the PRG key the display shows “n+old access

code” and the red display’s first digit begins to blink.

• Press the ▲ key until the blinking digit displays the de-

sired value.

• Press the PRG key. The next digit blinks.

• Press the ▲ key until the blinking digit displays the de-

sired value.

• Press the PRG key. The next digit blinks.

• Press the ▲ key until the blinking digit displays the de-

sired value.

• Press the PRG key. All of the display’s digits stop blink-

ing.

• To save the settings, while none of the display’s digits

are blinking, scroll the menu using the ▲ key until “Hld”

appears on the display and then press PRG key. The

pump returns to standby mode and “on” appears on the

display.

Menu 1,2,3: Manually set the pump time, delay, and

lockout times.

• Enter the programming mode.

• Press the ▲ key to select the menu.

• Press the PRG key to scroll between digits.

• Press the ▲ key to change the value.

• The maximum value is 999.

• Press the PRG key. All of the display’s digits will stop

blinking.

• To save the settings, make sure none of the display’s

digits are blinking, scroll the menu using the ▲ key

until “Hld” appears on the display and then press PRG

key. The pump returns to standby mode and “on” ap-

pears on the display.

Menu 4: Selecting the voltage tolerance.

• Press the PRG and ▲ key to set your tolerance.

• LO = 20-240VAC; HI = 70-240VAC

Menu 5: Calibrate using volume

• Enter the programming mode.

• Press the ▲ key until the display shows “5CAL”.

• Press the PRG key, CAL begins blinking.

• While holding a measuring cup or flask under the

output of the pump, press the ▲ key and release

when the pump starts (display starts counting). Let

the pump run until desired amount of chemical is

dispensed then press the ▲ key again to stop.

(display shows the dosing time). The OPL Mini run

time is now programmed. Repeat these steps if new

volume is required.

• Press the PRG key the display shows “5CAL”.

• To save the settings, scroll the menu using the ▲

key until “Hld” appears on the display and then press

PRG key. The pump returns to standby mode and

“sby” appears on the display.

When finished programming, move the switch back to

the “ON” position.

Getting Started: When the pump is powered, the display shows ON. Flip the switch on the bottom to “OFF” to enter

programming mode. The display will show “SBY”. The dosing and delay times are 0-999 seconds, the lock-out time is

0-999 minutes.

1. Accessing the menus

• Move the switch to “OFF”. SBY will display.

• Press the PRG key until the display shows “P---”.

• Use the PRG to scroll between values. Use the ▲ to

change the number. The default is 000.

• Press the ▲ and PRG key to enter your access code.

The default is 000.

• The maximum value is 999.

• The first menu will show a green 1 on the left.

Menu Structure: Indicated by the green number on the

left.

O: old access code

n: new access code

1: Delay Time

2: Pump Time

3: Lockout Time

4: Setting voltage tolerance

5: Calibration

Hld: save program using PRG key

Esc: Leave the menus

Rev B 92818 Page | 4

Troubleshooting

Problem Solution

The pump will not draw chemical

1.Check the the foot valve for debris.

2. Check the suction line for cracks or a break in vacuum.

The pump will not dispense chemical

1. Make sure the pump is powered.

2. Check the suction tube to make sure there are no

cracks.

3. Check the programming to make sure a run time is pro-

grammed.

Error Code:

“1Alr”

1. If the motor is excessively overloaded (i.e faulty tube)

the pump executes stop/restart motor cycles (the stop

time increases at every STOP: 0.5 sec . ->10 sec.) to

avoid overheating. Replace the tube.

Priming The Pump

Press the switch on to “MOM” (Momentary Switch). This will prime the pump for the dosing time that is programmed.

Default Settings

As soon as the pump is powered, the display shows “8888” for approximately 0.3 seconds, during which the pump runs

a check: If the parameters cannot be read properly from EEPROM, the display shows “FAIL“ and the pump remains on

standby. The default parameters can be reset using the ▲ key (pressed for 4 seconds).

The default settings are:

Delay time = 005

Dosing time = 055

Lock-out time = 000

Trigger signal = HI

Calibration = CAL

Old password = 000

After the default settings have been reset, these settings can be modified from the programming menu.

Exit Programming

To exit programming and return to the main menu, scroll the menu using the ▲ key until “ESC” appears on the display.

Now press PRG key. The pump returns to standby mode and “Sby” appears on the display. If you changed any values,

the settings will NOT be saved by exiting this way. Move the switch back to “ON” to operate.

Other Information

Rev B 92818 Page | 5

Terms & ConditionsTerms & Conditions

Company warrants its Goods to be free from material defects in material and workmanship for a period of one year ex-

cept: i. when Goods have been modified following delivery and/or subject to improper handling, storage, installation, op-

eration, or maintenance unless those modifications have been authorized in writing by Seller. ii. when an item is pur-

chased by Company as a component part of the Goods, except to the extent to which such item or items are covered by

the warranty, if any, of the original manufacturer. iii. when an item which is a component part of the product has been

furnished by Buyer. iv. no warranty of a component part shall extend beyond the warranty period of the device in which

such component part is incorporated. b. There is no implied warranty of merchantability or of fitness for particular pur-

pose and there are no warranties of any nature except as set forth in paragraph 3 herein. Any claim by Buyer made pur-

suant to Company’s warranty must be made in writing. Company shall have the right to inspect the Goods claimed to be

defective and shall have the right to determine the cause of such alleged defect. All Goods replaced or repaired by Com-

pany under its warranty shall be replaced or repaired F.O.B. Company’s facility. Buyer must notify Company, in writing,

within fifteen (15) days from receipt of Goods of any obvious defect in the product, or shortages, or Company shall have

no obligation to correct such defect. Company shall have the option of re-inspection at Buyer’s plant or its own before

allowing or disallowing Buyer’s claim. Defects that do not impair service shall not be a cause for rejection or recovery

under any warranty. Buyer assumes full responsibility for the use and application of the product. Buyer accepts Compa-

ny’s design and material selection and specifications in placing this order unless other specifications are agreed to in

writing by both parties prior to the manufacture of Goods by Company. Statements and data relating to Products on

Seller’s literature and website are not intended to define the performance of the product in actual usage or in com-

bination with other equipment or processes. These statements should not be used by Customer solely as an indication

of performance or suitability for specific applications or uses.

THE ABOVE WARRANTIES ARE THE SOLE AND EXCLUSIVE WARRANTIES MADE BY SELLER WITH RESPECT

TO ALL PRODUCTS AND SERVICES.

Components and spare parts such as O-rings, squeeze tubes, roller blocks and other plastic components are consid-

ered to be wear parts and are not warranted. Seller shall have no warranty or liability for product that was damaged dur-

ing shipment, product that is not being used in its recommended use, product that is not operated in accordance with the

operating manual and procedures, product that was not properly installed, product used in a manner that is inconsistent

with its designed purpose, product that is subject to a power surge or similar event, products that fail due to usage of a

non Lavo Solutions replacement or spare part or product that was not maintained in accordance with recommended

maintenance programs.

For full terms and conditions visit:

http://lavosolutions.com/LAVO-T&C-02-2018.pdf

Lavo Solutions, LLC

Worldwide Headquarters

23192 Verdugo, Suite #D

Laguna Hills, CA 92653

O: 949-377-1250

W: www.lavosolutions.com

Table of contents

Popular Dispenser manuals by other brands

Dispense-Rite

Dispense-Rite SLR-LID-2 Series installation instructions

BOWMAN

BOWMAN BD212-0023 manual

START International

START International LD8025 quick start guide

Alfa Network

Alfa Network Thor First Start Manual

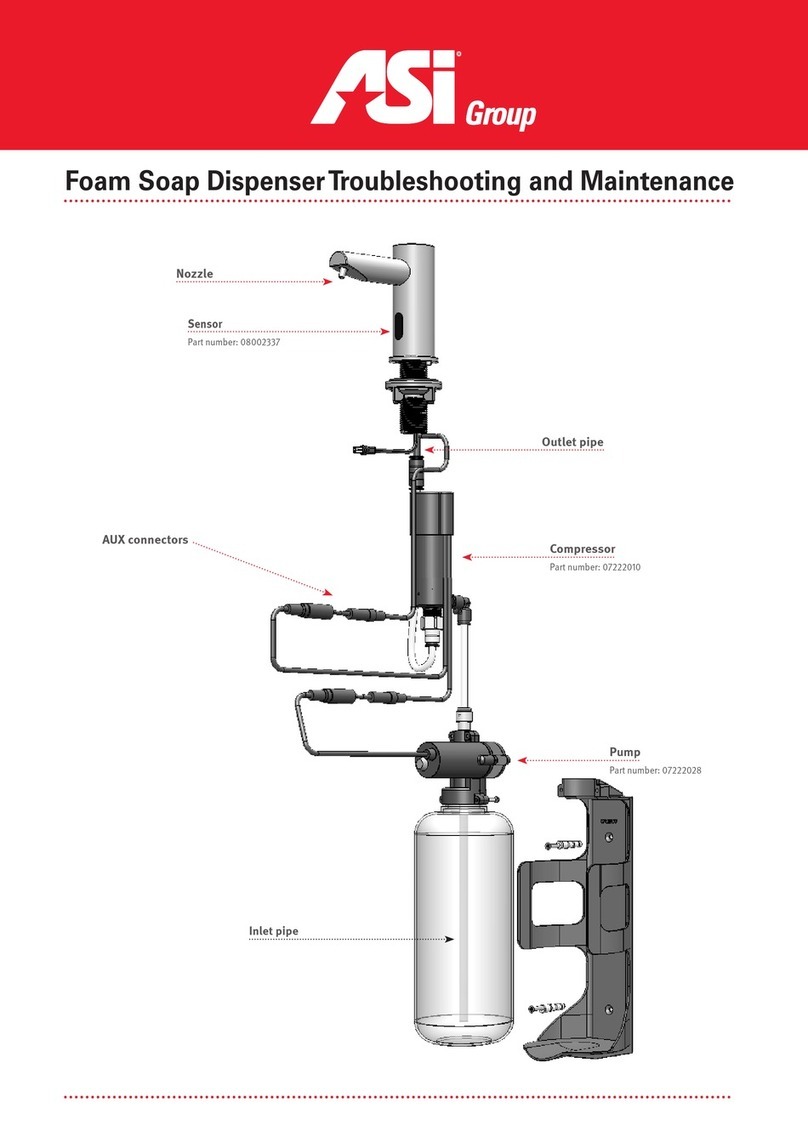

ASI

ASI EZ FILL Troubleshooting and maintenance guide

AUTOMATED EQUIPMENT

AUTOMATED EQUIPMENT McDonald's DF22 Equipment manual