Lawler AVAS Instruction Manual

Installation &

Maintenance Manual

M AVAS A

(1)

AVAS

Audio/Visual Alarm System

5330 East 25th Street

Indianapolis, Indiana 46218

Phone (317) 261-1212

Fax (317) 261-1208

Description

The Audio/Visual Alarm System is designed to give

a visual and audible warning in cases where water

temperature exceeds a pre-programmed setpoint. In

addition, the alarm system can control an optional

solenoid valve, shutting down the ow of water if

necessary. The probe temperature is displayed on

a bright 3-digit LED display, and access to the unit

programming is done thru the password protected

keypad on the front face. A keylock switch is pro-

vided to override the audible alarm.

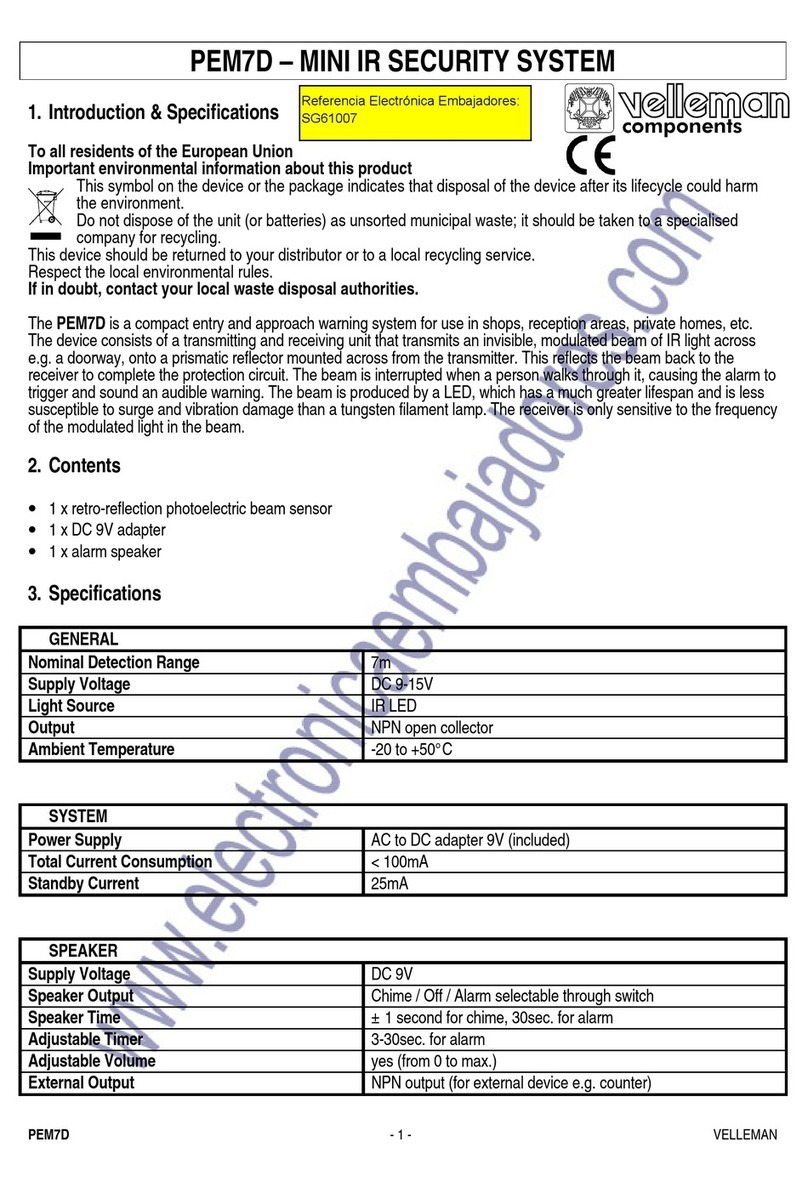

Specifications

Probe Range: -58 to +302°F

Input: Thermistor (1000Ω @ 25°C)

Accuracy: ±1°

Resolution: ±1 Digit

Supply Voltage: 120 VAC

Ambient Temperature: 32 to +131°F

Storage Temperature: -4 to + 176°F

Display: 3-digit, Red, ½″High

Installation

The Alarm System comes with a standard 120 VAC

pigtail. The controller uses a SPDT relay powering the

horn, and light, as well as an optional normally closed

solenoid valve. Please see Lawler Manufacturing,

Inc. about approved solenoid valves to use with the

alarm system so as not to overload the controller.

Observe proper polarity when connecting to the ter-

minal block on the back panel of the enclosure. The

wiring diagram can be found on page 3.

Upon powering the unit up the solenoid valve will

open allowing the ow of water. If the set point is

exceeded, the valve will close, and the audible and

visual alarms will come on. The audible alarm can

be bypassed with the keylock switch. The unit will

return to normal when the temperature goes below

the sum of the set point and the high alarm minus the

hysteresis.

Parameters

Code Description Range Default

SP Set Point r1 to r2 120°F

r0 Hysteresis 1 to 20 2°F

r1 Lower Value Set Point -50 to +150°F -50°

r2 Upper Value Set Point -50 to +302°F 200°F

d0 Heating or Cooling Ht/Co Co

d2 Time for Defrosting 0 to 59 Min 0 Min

d8 Interval between Defrost 1 to 24 Hrs 1 Hr

c0 Min. Stop Time 0 to 59 Min Load 0 Min

c1 Continuous Cycle Time 0 to 24 Hrs 0 Hrs

c2 On Time of Fault Cycle 0 to 999 Min 0 Min

c3 Off Time of Fault Cycle 0 to 999 Min 0 Min

A0 Alarm differential/hysteresis 1° to 20° 5° F

A1 Max alarm temp 1° to 20° 10° F

A2 Min alarm temp 1° to 20° 90° F

A7 Alarm time valaidation 0 to 99 Min 0 Min

P0 Temperature Scale Option 0/F°

P1 Ambient Probe Adj. -10 to +10°F 0°F

P4 Decimal Point Option No

H0 Factory Settings Option 0

H4 Address 0 to 999 0

H5 Parameter Access Code 00 to 99 00

H6 Ambient Probe Type Option PTC

t0 Max Temp on Display -50 to +302°F 200°F

(2)

The actual point of alarm is the sum of the set

point and the "high alarm". The system will re-

turn to normal when the temperature reaches the

sum of the set point and the "high alarm" minus

the hysteresis.

Parameter Programming

Set Point (SP) is the only parameter the user

can access without code protection

• Press SET. SP Text will appear on the display

• Press SET again. The real value is shown on the

display.

• The value can be modied with the UP and DOWN

arrows.

• Press SET to enter any new values.

• Press SET and DOWN at the same time to quit

programming or wait one minute and the display

will automatically exit programming mode.

The keyboard code can be reset to ZERO by

turning off the controller and turning it on again

while keeping the SET key depressed.

Access to all code protected parameters.

• Press SET for 8 seconds. The access code value

00 is shown on the display. (Unit comes with code

set at 00 from factory).

• With the UP and DOWN arrows, code can be set

to user needs.

• Press SET to enter the code. If code is correct, the

rst parameter label is shown on the display (SP).

• Move to the desired parameter with the UP and

DOWN arrows.

• Press SET to view the value on the display.

• The value can be modied with the UP and DOWN

arrows.

• Press SET to enter the value and exit to text pa-

rameter.

• Repeat until all necessary parameters are modied.

• Press SET and DOWN at the same time to quit

programming or wait one minute and the display

will automatically exit programming mode.

Display Messages

In normal operation, the probe temperature will be

shown on the display. In case of alarm or error, the

following messages will be shown: The alarm LED

indicates and active alarm, it will ash if an alarm is

cleared but alarm condition still exists.

• ALH = High Temp Alarm

• ALL = Low Temp Alarm

• Er = Memory Error

• -- = Short-Circuit Probe Error

• oo = Open Probe Error

Alarm can be cleared by pressing the DOWN button.

The alarm LED will ash while alarm condition per-

sists but the alarm message will not be shown.

Warning: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

(Installer: California law requires that this warning be

given to the consumer.)

For more information: www.oehha.org/prop65

GUARANTEE

We guarantee the Lawler Mixing Valve to be free from

def ects in workmanship and material, and for a pe-

riod of one year from date of purchase, will replace

any parts found by us to be defective. We will not be

held responsible, however, for any labor incidental

to, or for any damages caused by defective mate-

rial. Each mixing valve is thoroughly inspected and

tested under actual conditions at our factory.

(3)

AVAS Wiring Diagram