–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralbeforestartingengine.

Starttheengineonlyfromtheoperator’sposition.

•Neveroperatewithouttheshields,covers,orother

guardssecurelyinplace.Besureallinterlocksare

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Raisetheblades,stopthemachine,andstopthe

enginebeforeleavingtheoperator’spositionforany

reason.

•Stoptheequipmentandinspectthebladesafter

strikinganobjectorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperation.

•Keephandsandfeetawayfromthebladearea.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdown,andusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroads

andsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Alwaysbeawareofobstaclesthatmaybeinthearea

ofoperation.Planyourpathtoavoidcontactwith

anyobstaclebyyouorthemachine.

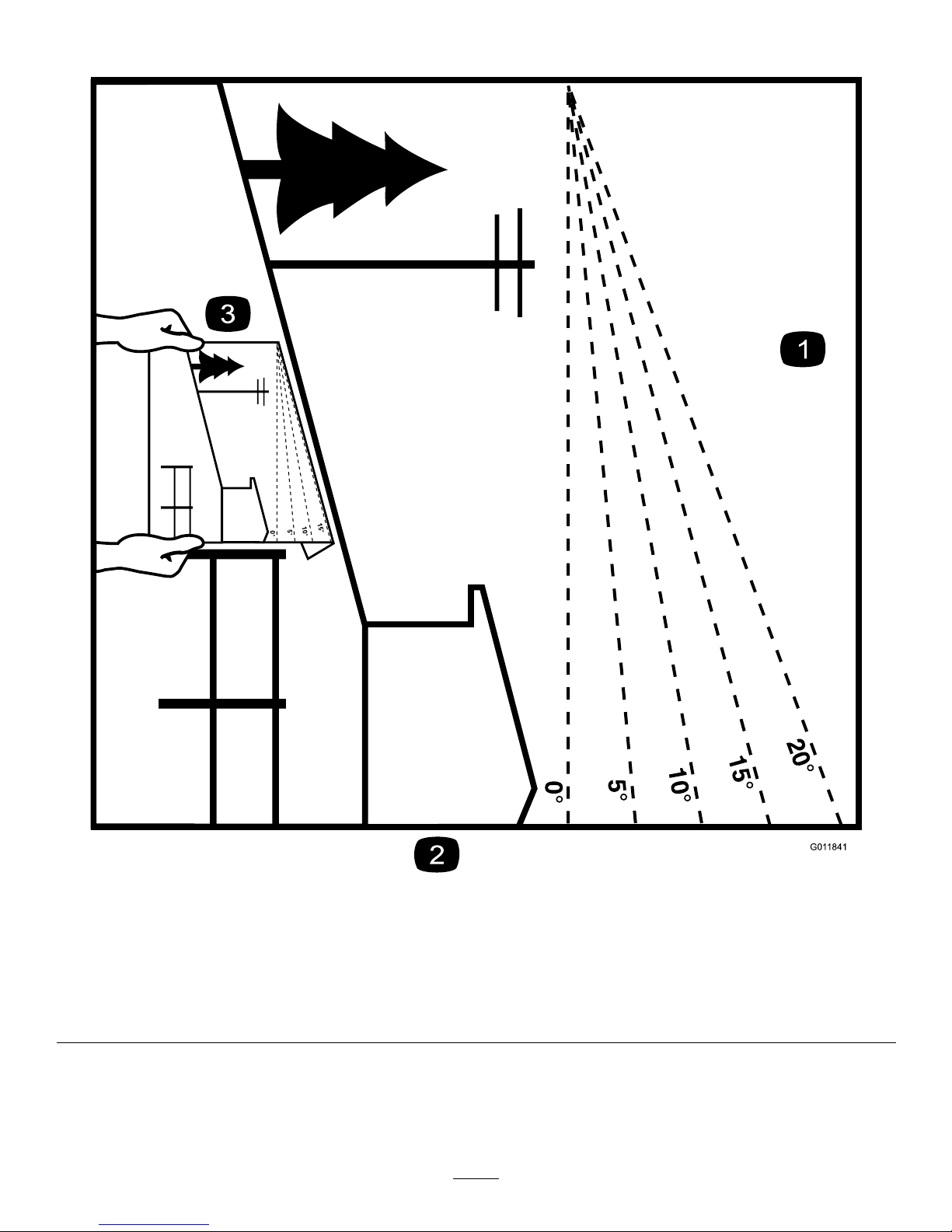

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanks,

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjuryordeath.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Donotoperateonaslopegreaterthan20degrees.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromtheoperatingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followtherecommendationsforwheelweightsor

counterweightstoimprovestability.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.Raisetheblades,stopthe

machine,stoptheengine,anddisconnectthespark

plugwire.

•Cleangrassanddebrisfromtheblades,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Shutoffthefuelwhilestoringortransportingon

trailers.Donotstorefuelnearamesordrain

indoors.

•Parkthemachineonlevel,hardground.Neverallow

untrainedpersonneltoserviceit.

•Usejackstandsorsafetylatchestosupport

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Removethesparkplugwiresbeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyLawnSolutions-approvedattachments.

Thewarrantymaybevoidedifthemachineisused

withunapprovedattachments.

4