LAWO mc256 MKII User manual

Technical Manual

mc²56 MKII

Version: 5.10.2/1

Edition: 12 September 2017

Copyright

All rights reserved. Permission to reprint or electronically reproduce any document or graphic in whole or

in part for any reason is expressly prohibited, unless prior written consent is obtained from the Lawo AG.

All trademarks and registered trademarks belong to their respective owners. It cannot be guaranteed that

all product names, products, trademarks, requisitions, regulations, guidelines, specifications and norms

are free from trade mark rights of third parties.

All entries in this document have been thoroughly checked; however no guarantee for correctness can be

given. Lawo AG cannot be held responsible for any misleading or incorrect information provided throughout

this manual.

Lawo AG reserves the right to change specifications at any time without notice.

© Lawo AG, 2017

mc²56 MKII Technical ManualV5.10.2/14

Welcome

Welcome

Welcome to the mc²56 MKII Technical Manual.

About this Manual

This documentation covers the installation, configuration and service/maintenance of the mc²56 MKII. The

specification is valid for mc2Version 5.10.2.x.

For more on operation, please see the "mc²56 MKII Operators Manual". All Lawo manuals are available from the

Download-Center at www.lawo.com (after Login).

Look out for the following which indicate:

Notes - points of clarification.

Tips - useful tips and short cuts.

Warnings

Alert you when an action should always be observed.

Software Updates

Lawo employ an ongoing development programme and offer free-of-charge software updates for all mc2/Nova

products. Releases can be downloaded from the Lawo website (after Login).

Utility Software Applications

The mxGUI installer is free to download from the Lawo website (after Login). Once installed, you can launch all

utility software applications including:

·

mxGUI - for offline setup or remote operation of the console.

·

AdminHD - to edit the system configuration.

·

CFCard Creator - to create backup CF Cards for the control system and, in a console, the bay server(s).

·

mxUpdater - to update the software of the mc2/Nova control system, or backup and restore user data.

Lawo User Registration

For access to the Download-Center and to receive regular product updates, please register at:

www.lawo.com/user-registration.

Additional Information

The "mc2_documentation" contains mechanical drawings, data sheets and further information on all system

components. This resource is included with the current mc2_56 software release, available from the Download-

Center at www.lawo.com (after Login).

We also recommend that you carefully observe the release notes delivered with your system.

mc²56 MKII Technical Manual V5.10.2/1 5

Important SafetyInstructions

Important Safety Instructions

General Safety

Warning

Exposure to excessive sound pressure levels can lead to impaired hearing and cause damage to the ear.

Please read and observe ALL of the following notes:

·

Check all of the hardware devices for transport damage.

·

Any devices showing signs of mechanical damage or damage from the spillage of liquids MUST NOT

be connected to the mains supply or disconnected from the mains immediately by pulling out the

power lead.

·

All devices MUST be grounded. Grounding connectors are provided on all devices. In addition, all

low-voltage devices external to the system must also be grounded before operation.

·

For Scandinavian countries, ALWAYS use a grounded mains connection, to prevent the device from

being grounded through Ethernet or other signal connections.

·

Do NOT use the system at extreme temperatures - observe the temperature range and humidity

specified in the installation instructions.

·

Do NOT expose devices to liquids which may drip or splash.

·

Do NOT place objects filled with liquids, such as vases, upon a device.

·

Only service staff may replace batteries.

·

CAUTION: Danger of explosion if battery is incorrectly replaced - Replace only with the same or

equivalent type.

Servicing of components inside a device MUST only be carried out by qualified service personnel according

to the following guidelines:

·

Before removing parts of the casing, shields, etc. the device MUST be switched off and disconnected

from all mains.

·

Before opening a device, the power supply capacitor MUST be discharged with a suitable resistor.

·

Components that carry heavy electrical loads, such as power transistors and resistors, should NOT

be touched until cool to avoid burns.

Servicing unprotected powered devices may only be carried out by qualified service personnel at their own

risk. The following instructions MUST be observed:

·

NEVER touch bare wires or circuitry.

·

Use insulated tools ONLY.

·

DO NOT touch metal semi-conductor casings as they can bear high voltages.

Eye Safety

Warning

This equipment may use Class 1 Laser products which emit invisible laser radiation that may lead to eye

injury.

·

NEVER look directly into optical components or optical fibre cables.

·

Fit protection caps to close any unused optical components.

·

Connect all optical fibre cables BEFORE turning on the equipment.

mc²56 MKII Technical ManualV5.10.2/16

Important SafetyInstructions

Defective Parts/Modules

Warning

mc²56 MKII contains no user-serviceable parts. Therefore DO NOT open the devices other than to perform

the procedures described in this manual.

In the event of a hardware defect, please send the system component to your local service representative

together with a detailed description of the fault. We would like to remind you to please check carefully

whether the failure is caused by erroneous configuration, operation or connection before sending parts for

repair. Please contact our service department before sending parts for repair.

First Aid (in the case of electric shock)

Warning

DO NOT touch the person or his/her clothing before power is turned off, otherwise you risk sustaining an

electric shock yourself.

Separate the person as quickly as possible from the electric power source as follows:

·

Switch off the equipment.

·

Unplug or disconnect the mains cable.

·

Move the person away from the power source by using dry insulating material (such as wood or

plastic).

If the person is unconscious:

·

Check their pulse and reanimate if their respiration is poor.

·

Lay the body down and turn it to one side. Call for a doctor immediately.

Having sustained an electric shock, ALWAYS consult a doctor.

mc²56 MKII Technical Manual V5.10.2/1 7

Chapter 1: Technical Overview

Chapter 1: Technical Overview

This chapter introduces the technical components of the mc²56 MKII system:

·

Hardware Components

·

RAVENNA Interfaces

·

Redundancy

·

Sample Rate & System Clock

·

Networking I/O Resources

·

IP-SHARE Gain Compensation

·

Configuration

·

System Options

mc²56 MKII Technical ManualV5.10.2/18

Chapter 1: Technical Overview

Hardware Components

Hardware Components

The mc²56 MKII consists of three principal components:

·

Console control surface - with integrated power supplies and local I/O connections.

·

Nova73 – with Router Modules, DSP boards and AES, MADI, RAVENNA or DANTE I/O. Available in two

sizes: Nova73 HD (10RU) or Nova73 Compact (7RU).

·

DALLIS or Compact I/O – offering further I/O breakout options. DALLIS frames can be fitted with a

choice of I/O cards and connect to the Nova73 via MADI or RAVENNA. The Compact I/O is a 5RU

stagebox with a fixed amount of I/O; it connects to the Nova73 via RAVENNA Link.

The exact hardware specification defines how many analogue and digital connections are available for external

equipment, and how much DSP processing is available for input channels, monitor return channels, groups, sums

and auxiliary sends.

From Version 5.4 onwards, two identical control surfaces can connect to the same Nova73 in order to mirror

each other - for example, in a theatre you can install one surface in the auditorium and the other in a

separate control room to facilitate mixing from two different locations. The surfaces MUST be from the same

console family (either mc256 OR mc266), but different frame sizes are possible. For more details, see

Installing a Mirror Desk.

mc²56 MKII Technical Manual V5.10.2/1 9

Chapter 1: Technical Overview

Hardware Components

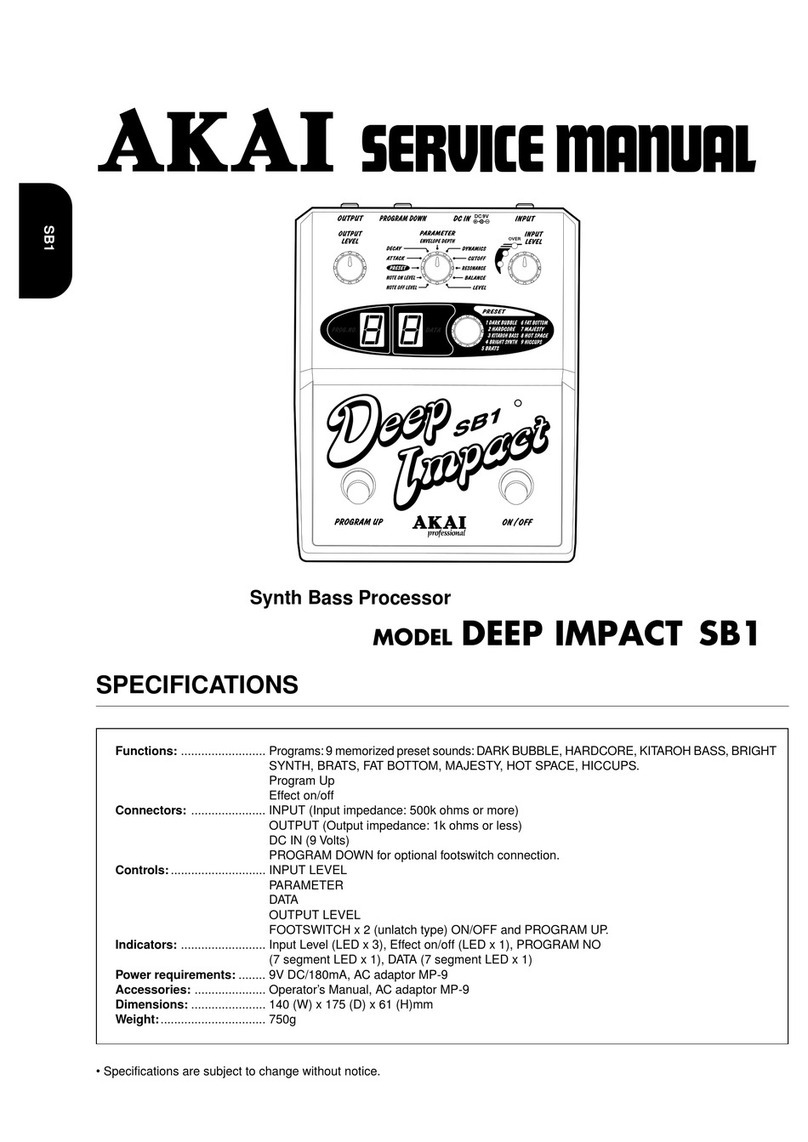

Console Control Surface

The mc²56 MKII control surface is constructed in 16-fader sections, with frame sizes scaling from 16 faders up to

80 faders. you can add 16-fader extenders to expand the number of fader strips.

A range of console options offer wide (studio) or narrow (OB) side panels, table-top or stand mounting, overbridge

metering, etc.

Control surface power is provided by internal power supplies, with n+1 redundancy and two mains connections for

phase redundancy. PSU status can be monitored from the console GUI.

All application software and user data is handled by the control system, located on the Router Module MKII within

the Nova73. The surface connects to the Nova73 via TCP/IP Ethernet; if a redundant Router Module is fitted, then

main and backup connections can be installed.

The control surface also houses a local I/O board, for monitoring, metering, talkback and headphones. This is

available in two versions, connecting to the Nova73 via either MADI or RAVENNA.

As the control system is integrated within the Nova73, the control surface can be powered off without loss of

user data or audio!

mc²56 MKII Technical ManualV5.10.2/110

Chapter 1: Technical Overview

Hardware Components

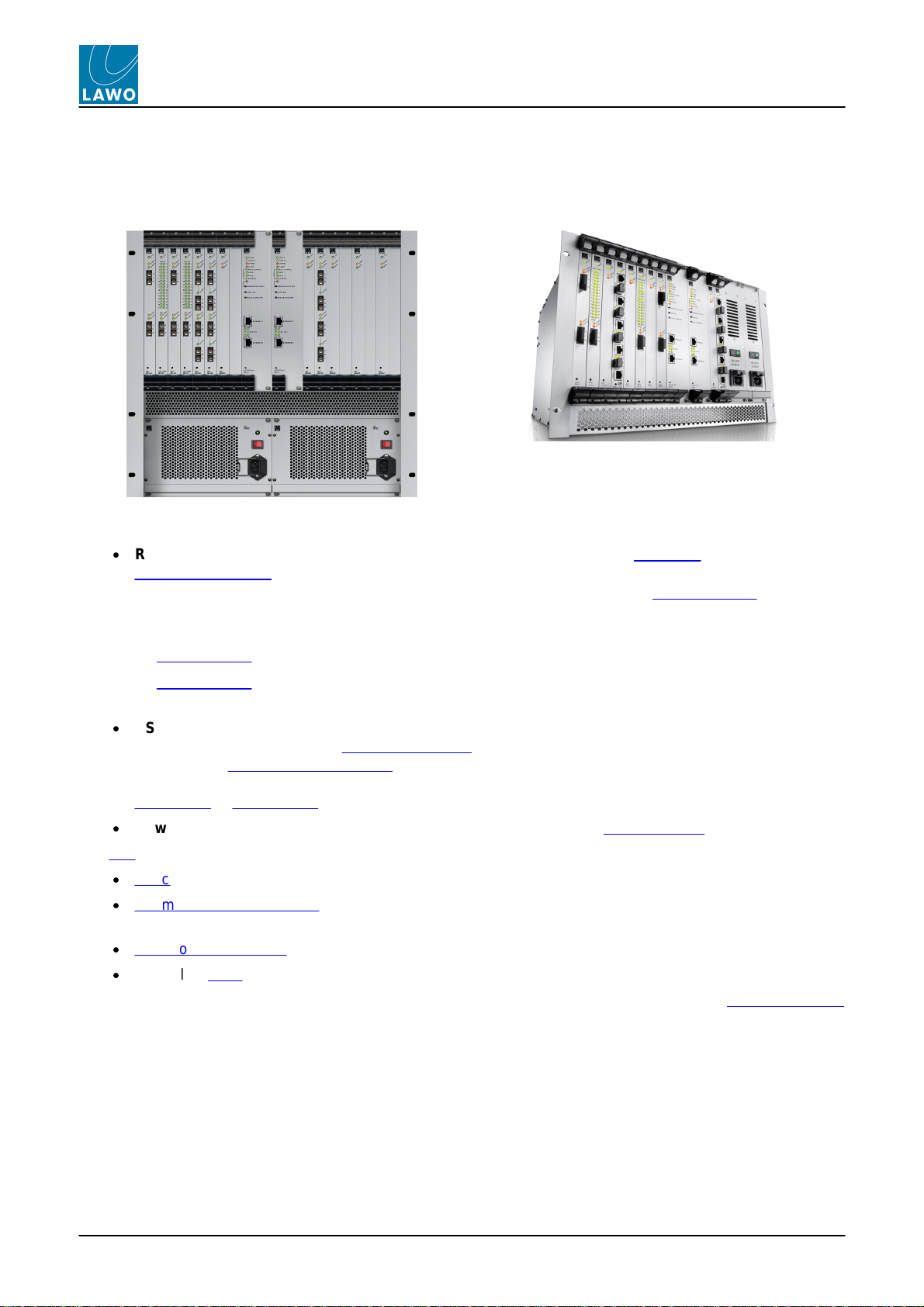

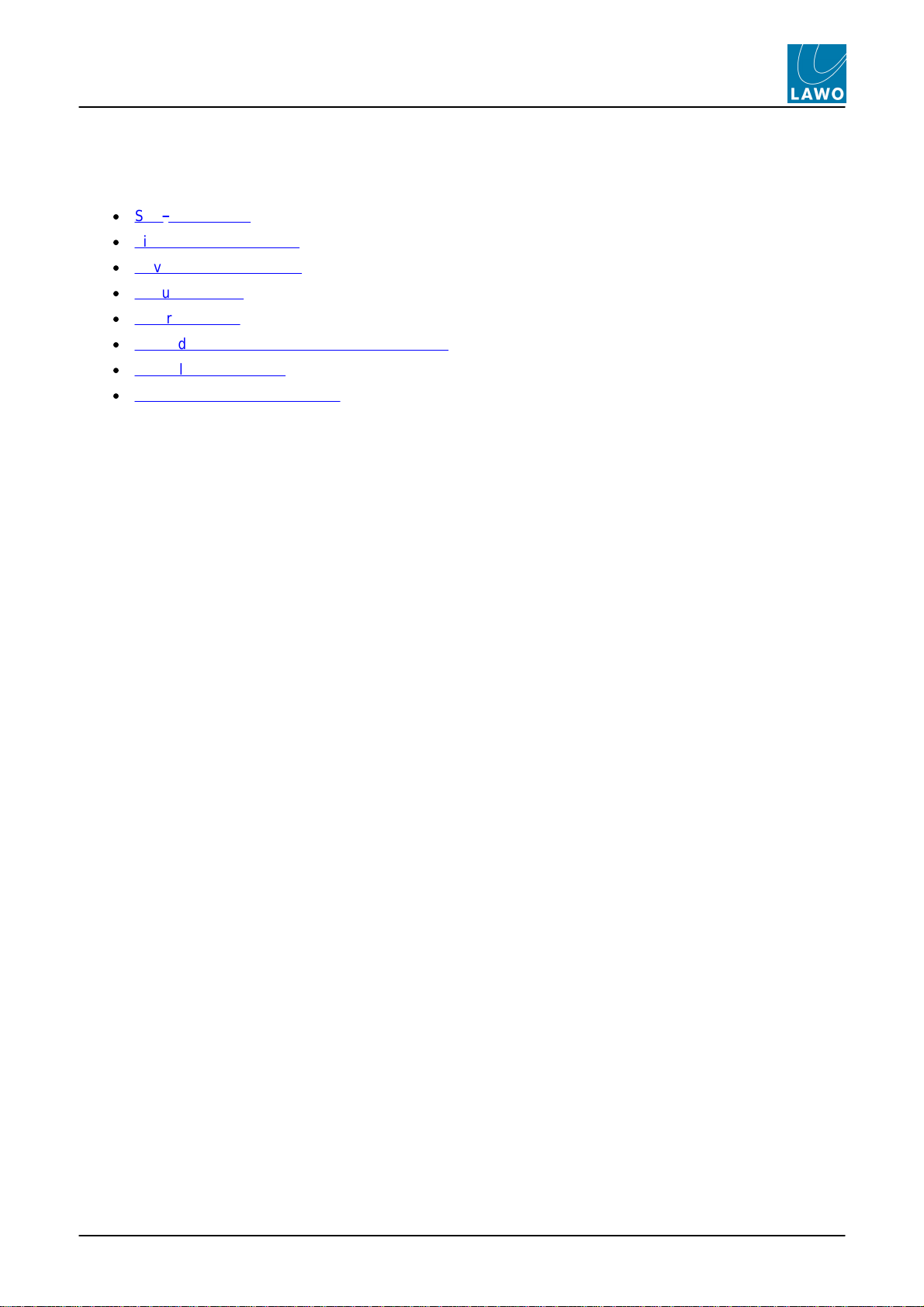

Nova73

The Nova73 forms the "heart" of the system, and is available in two sizes - Nova73 HD (10RU) or Nova73

Compact (7RU):

Nova73 HD (10RU)

Nova73 Compact (7RU)

In each case, the front of the frame houses the:

·

Router Modules MKII - two central slots are available for a main and redundant Router Module. The

Router Module MKII (980/33) contains the summing matrix AND control system. The summing matrix

offers a 8k2capacity* router at 48kHz (or 4k2capacity at 96kHz). The control system runs on an

embedded Linux operating system, and stores both the application software and user data. Connections

are made via the two TCP/IP Ethernet ports:

oETHERNET A – connects to the control surface.

oETHERNET B – connects to the Lawo system network (to other Lawo devices; third-party controllers;

computers running configuration, maintenance or remote control software).

·

DSP and I/O Modules - 16* slots are available for plug-in DSP or I/O modules. Up to 8* DSP boards can

be fitted supporting a range of DSP configurations; I/O options include AES/EBU, MADI, RAVENNA and

DANTE, see Nova73 Module Options. All modules are hot-pluggable enabling them to be be replaced

without affecting other aspects of the system. Further breakout formats are realised by connecting to

DALLIS I/O or Compact I/O stageboxes.

·

Power Supply Units - two slots are available for main and redundant power supplies.

The rear of the frame houses the:

·

Sync ports - accepting Wordclock, AES/EBU (AES3-id) or Video Black Burst (PAL or NTSC).

·

Alarm and control contacts - including a global alarm; prepare cold start; force redundant Router Module

takeover.

·

AES connector panels - for front-mounted AES3 I/O modules.

·

5* Cooling Fans - hot-pluggable and easily accessible.

* The figures above are for the Nova73 HD. For more details on the Compact core, see the Nova73 Compact

Appendix.

mc²56 MKII Technical Manual V5.10.2/1 11

Chapter 1: Technical Overview

Hardware Components

DALLIS I/O

Front View

Rear View

The I/O capabilities of the system are expanded by adding DALLIS unit(s). Each can be either 3RU (shown

above) or 6RU in height, and may be remote from the rest of the system.

The front of the frame houses the:

·

DALLIS Master Boards - two central slots are provided for a main and redundant master board. A choice

of board types provide connection to/from the Nova via MADI or RAVENNA, see DALLIS Interface

Options.

The type of DALLIS master board, and hence the connection, determines the maximum number of audio

channels to/from the Nova: up to 60 (MADI) or 128 (RAVENNA).

·

DALLIS I/O cards - 18 slots are available for a range of I/O breakout options (Mic/Line, Line, AES, SDI,

GPIO, etc.), see DALLIS Interface Options.

All cards are hot plug-able, with the exception of Phantom Power.

The rear of the frame provides access to:

·

Main and redundant power supplies

·

Alarm and control contacts - including a local DALLIS alarm.

mc²56 MKII Technical ManualV5.10.2/112

Chapter 1: Technical Overview

Hardware Components

Compact I/O

Front View

As an alternative to DALLIS I/O, the Compact I/O is a 5RU stagebox with a fixed amount of I/O that connects to

the Nova via RAVENNA technology.

Each unit provides 32 mic/line in, 32 line out, 8 AES in, 8 AES out, 8 GPIO and 1 MADI port, and is fitted with

dual redundant power supplies. Each stagebox is delivered as a self-contained unit and comes with the required

RAVENNA network cable.

From Version 5.10.0 software onwards, the Compact I/O can connect via either RAVENNA Link or RAVENNA

Net - the type of connection is defined in the AdminHD configuration. Note that it is important to connect to the

correct port. Connections are made using standard CAT 5/6/7 Gigabit Ethernet, RJ45 connectors, crossed or

straight (1:1) cable, up to 80m. A network cable is delivered with the Compact I/O.

Using RAVENNALink

RAVENNA Link connections must be directly wired. Providing the correct RAVENNA port is connected (to match

the AdminHD configuration), the interface is self-configuring. Thus, once you have connected the ports (e.g. from

the Nova to Compact I/O), no further network configuration is necessary.

Warning

To guarantee low latency, reliability and easy setup, do NOT connect any other network equipment between

RAVENNA Link connections.

Using RAVENNANet

RAVENNA Net connections must be made via the streaming network (i.e. to the RAVENNA network switch). This

will ensure that the network's PTP clock signal (essential for RAVENNA streaming) is available to the streaming

port. In this instance, you must make sure that the correct RAVENNA role names are configured (within

AdminHD and each partnering device) and, in the case of any virtual devices, that the streaming IP address is

also defined. For full details, please refer to the "RAVENNA for mc2/Nova User Guide".

Warning

RAVENNA streaming requires proper configuration and management of the data network. The network must

use a suitable architecture; all components must support multicast (as opposed to unicast); a proper Quality

of Service (QoS) must be configured; and so on. Please DO NOT attempt to connect RAVENNA interfaces

using an unknown or unqualifying IP network. If you do so, correct streaming operation cannot be

guaranteed.

For more details, see RAVENNA Interfaces.

mc²56 MKII Technical Manual V5.10.2/1 13

Chapter 1: Technical Overview

Hardware Components

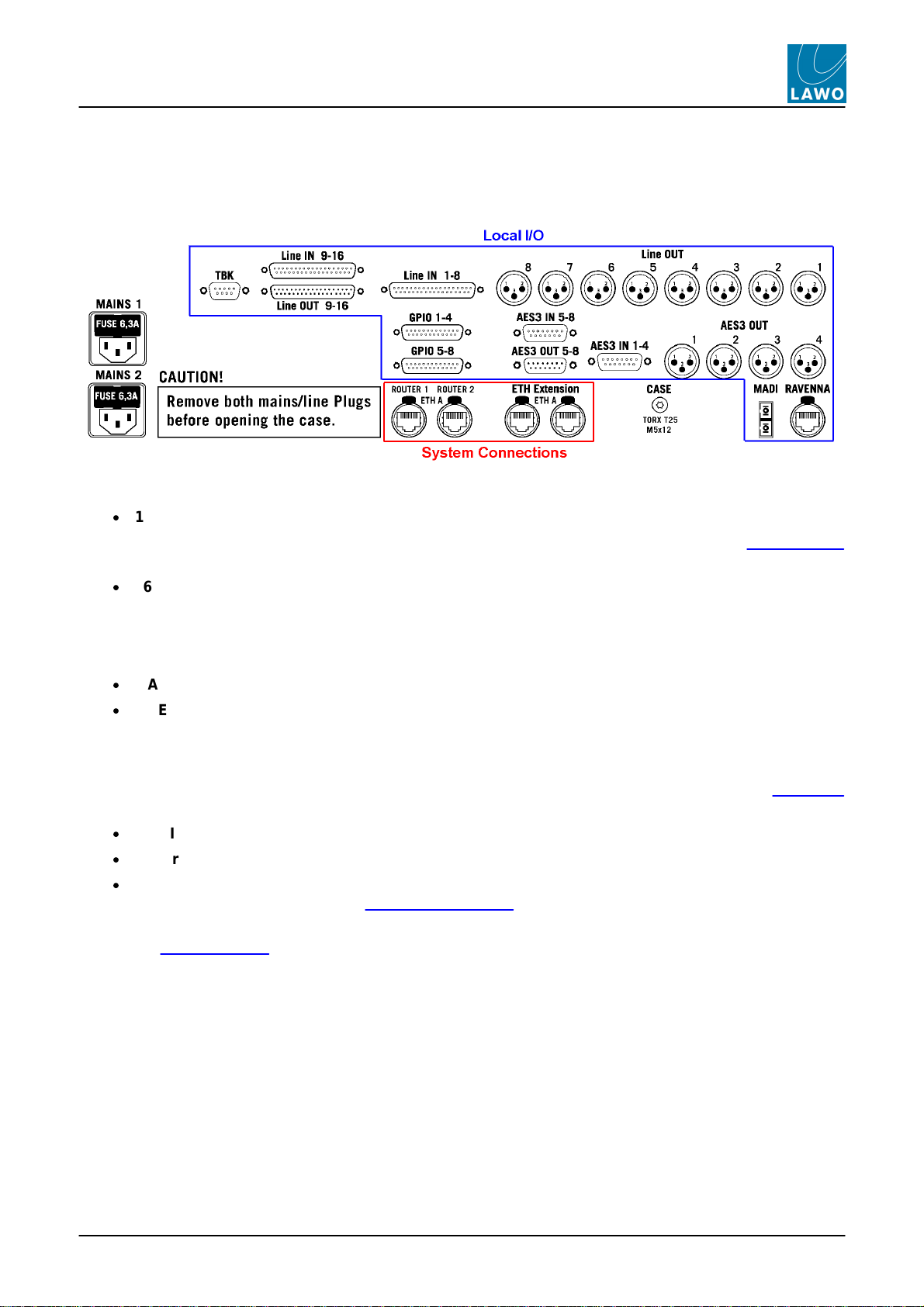

Local I/O

The mc256 MKII control surface includes an integrated local I/O board. This provides dedicated connections for

local devices such as monitoring, metering, talkback and headphones.

All local I/O connections are accessed from the control surface rear panel:

The local I/O provides:

·

16 Line In - wired to 2 x DSub (female).

Note that Line In 16 can be fed from the integrated talkback mic preamp, according to the jumper switch

positions set for the Local I/O.

·

16 Line Out:

oLine Out 1-8 - wired to 8 x XLR (male). By default, these outputs are routed from the CRM 1 monitor

output.

oLine Out 9-16 - wired to 1 x DSub (male).

·

8 AES3 In - wired to 2 x DSub (female).

·

8 AES3 Out:

oAES3 Out 1-4 - wired to 4 x XLR (male).

oAES3 Out 5-8 - wired to 1 x DSub (male).

Note that AES IN 5-8 and AES OUT 5-8 connect to the RTW meter, if either of the TM 7 or TM 9 Overbridge

options are fitted.

·

8 GPIO - wired to 2 x DSub.

·

2 Stereo Headphones - wired to the headphone 1 & 2 connectors on the console's front buffer.

·

1 MADI or 1 RAVENNA - the local I/O board is available in two versions, connecting to the Nova73 via

either MADI or RAVENNA (see Local I/O Connection). You will need to reserve one MADI, or one

RAVENNA, port within the Nova73 for this connection.

Please see Local I/O Wiring for more details on wiring, pin-outs and jumper switch options.

mc²56 MKII Technical ManualV5.10.2/114

Chapter 1: Technical Overview

RAVENNAInterfaces

RAVENNA Interfaces

RAVENNA is implemented throughout the Lawo product range. In mc2/Nova systems, it can be used to replace

MADI as the audio interconnect between the Nova routing matrix and DALLIS stageboxes. Or, to distribute

signals to other RAVENNA-compatible devices.

In this example two different types of RAVENNA are in use:

·

RAVENNA Net (IP Layer 3) - for connections to remote DALLIS and other RAVENNA-compatible devices.

·

RAVENNA Link 1.0 - a proprietary implementation of RAVENNA used for directly-wired connections (up

to 80m).

RAVENNA "Links" (Link 1.0) are recommended for local point-to-point connections such as those from the

console's Local IO and DALLIS units to the system Core (e.g. Nova73). This is because, once they are defined by

AdminHD, the Links are self-configuring and have no impact on the streaming network's bandwidth or

configuration. RAVENNA Links must be directly wired; connection via a network switch is not permitted.

RAVENNA "Net" (IP Layer 3) offers more flexibility as signals are distributed via the IP network. Each streaming

port can be configured as a DALLIS, Virtual Devices or Tie-line port supporting up to 128 bi-directional channels.

DALLIS ports may connect to a single 128-channel, or two 64-channel DALLIS frames, making RAVENNA more

flexible and port-efficient than its MADI equivalent. Virtual Device ports support up to 16 x 8-channel devices

including Lawo's A__line and LCU (Lawo Commentary Unit), and Neumann's DMI-8. RAVENNA Tie-Lines should

be configured to support streaming to/from other RAVENNA-compatible devices. Synchronization of the

RAVENNA streaming network requires a PTP master clock source. This can be achieved by using one of the

RAVENNA nodes as PTP master or by installing a third-party PTP Grandmaster device.

For more information on installing, connecting and configuring a RAVENNA network, please see the separate

"RAVENNA for mc2/Nova User Guide" and "RAVENNA Networking Guide".

mc²56 MKII Technical Manual V5.10.2/1 15

Chapter 1: Technical Overview

Redundancy

Redundancy

One of the strengths of the mc²56 MKII is its ability to withstand component failures, and every component is

designed with fault tolerance in mind:

·

Star2Technology

·

Link & Port Redundancy

·

Nova73 & DALLIS Power

·

Redundant DSP

·

Control System

·

Redundant Router Module and Control System

·

Control Surface Power

·

Control Surface Internal Wiring

mc²56 MKII Technical ManualV5.10.2/116

Chapter 1: Technical Overview

Redundancy

Star2 Technology

All components within the system utilise Lawo’s Star2technology:

·

Point-to-point connections – with point-to-point connections, a fault only affects that part of the system,

unlike a TDM bus architecture where a fault may disrupt everything connected to the bus!

·

Dual star topology – with redundant Router Modules fitted to the Nova73, and redundant Master Boards

in every DALLIS, then components connect in a dual ‘star’ mode. This protects signal paths from any

single point-of-failure. See Link & Port Redundancy.

·

Hot-swappable Modules/Cards – every plug-in module or card can be hot-swapped without affecting the

rest of the system enabling online maintenance of the system.

·

Redundant Power Supply Units – both Nova73 and DALLIS units can be fitted with dual redundant

power supplies, which can be isolated and exchanged from the front or rear. See Nova73 & DALLIS

power.

·

Passive backplanes – the frame backplanes are entirely passive. With no active components, this

increases reliability.

mc²56 MKII Technical Manual V5.10.2/1 17

Chapter 1: Technical Overview

Redundancy

Link & Port Redundancy

For crucial interconnections between say a DALLIS and mc2/Nova I/O Module, you can specify either link, or link

and port, redundancy:

·

Link Redundancy – two physical connections (MADI or RAVENNA) are made from the DALLIS master

board to the mc2/Nova module. If the active link fails, then the redundant link ensures an automatic

recovery.

·

Link & Port Redundancy - two master boards are fitted to each DALLIS, and connect to different

mc2/Nova ports (preferably on a different module). Port redundancy provides automatic recovery from a:

oFailure of the active physical link (MADI or RAVENNA).

oMalfunction of the active DALLIS master board.

oMalfunction of the mc2/Nova module.

To specify link redundancy:

·

MADI - order a double-port Nova73 module and DALLIS master board for each connection.

·

RAVENNA - install both the copper and fibre optic connections from the RAVENNA module / master

board.

To specify link & port redundancy:

·

MADI or RAVENNA - order two master boards per DALLIS plus enough single-port Nova I/O modules to

support the connections. AdminHD configures which ports provide redundancy.

mc²56 MKII Technical ManualV5.10.2/118

Chapter 1: Technical Overview

Redundancy

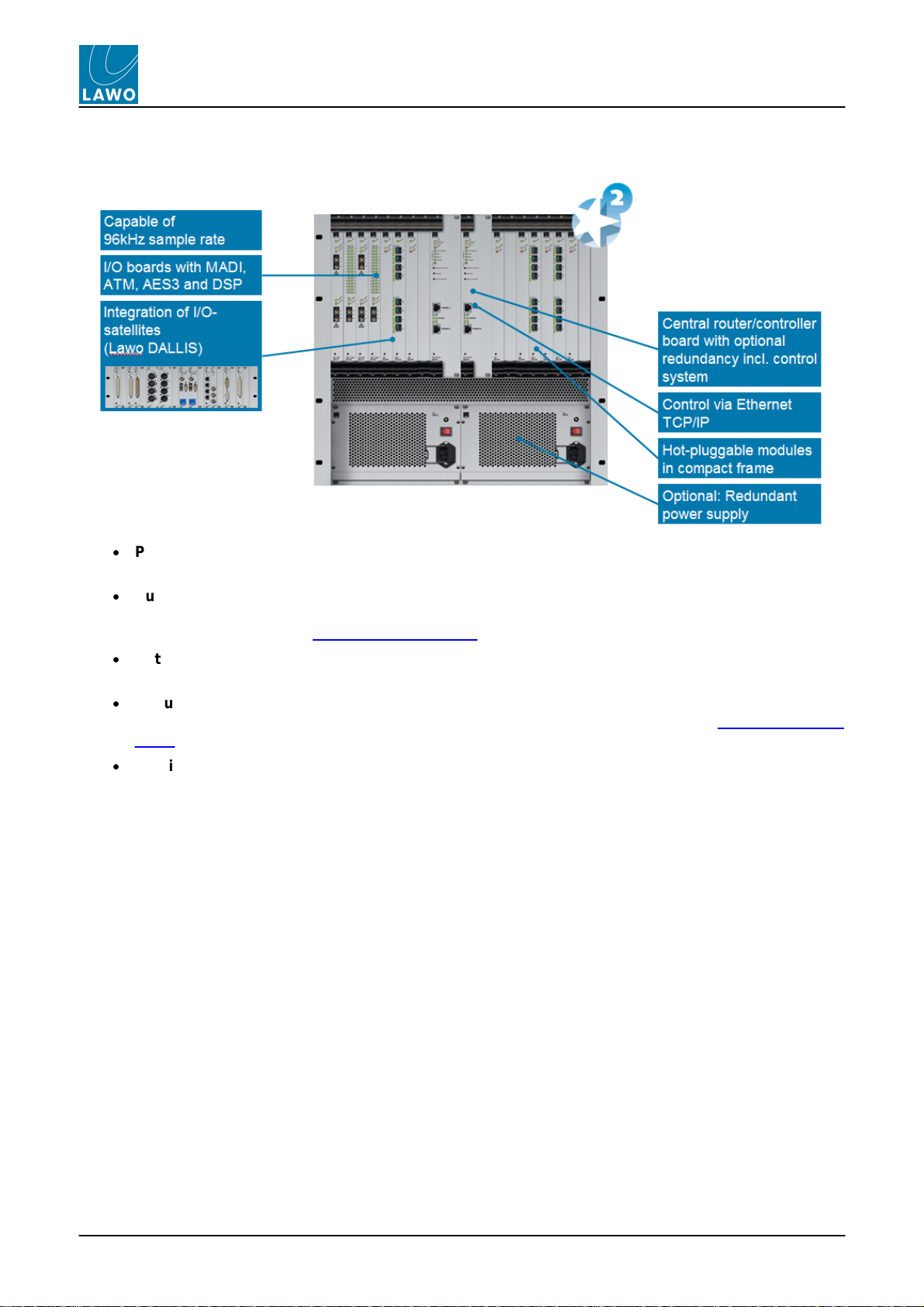

Nova73 & DALLIS Power

Nova73 HD front view

Nova73 Compact front view

DALLIS internal view of PSUs

The Nova73 HD, Nova73 Compact and DALLIS provide two slots for dual redundant power supplies, see Nova73

power and DALLIS power. Their status can be monitored from the console GUI using the Signal Settings display.

mc²56 MKII Technical Manual V5.10.2/1 19

Chapter 1: Technical Overview

Redundancy

Redundant DSP

Within the Nova73 a DSP board can be reserved to provide redundant processing (indicated by the STANDBY

LED).

In the unlikely event of a failure, the system automatically switches all DSP resources and settings from the faulty

board to the spare; the faulty board can then be safely removed and replaced.

This option is enabled from the console GUI using the DSP Configurations display, and is saved within the

production.

mc²56 MKII Technical ManualV5.10.2/120

Chapter 1: Technical Overview

Redundancy

Control System

The control system resides on the Router Module MKII (980/33).

It runs on an embedded Linux operating system for speed and increased

reliability, and stores both the application software and user data.

The Router Module MKII (980/33) contains a backup power unit

which provides up to 3 seconds of backup power to deal with short

interruptions to mains (AC) power.

WarmStart & Cold Start

Following switch-off, power is provided to the control system for a further 18 seconds. During this time, all current

settings are saved to flash memory; this is known as the system's warm start data.

By default, the warm start data is loaded at the end of boot-up. This means that the console comes back exactly

as it was when you last shut down, ensuring fast recovery of all previous settings following a loss of power.

Alternatively, you can perform a cold start if you suspect a problem with the warm start data.

Data Recovery

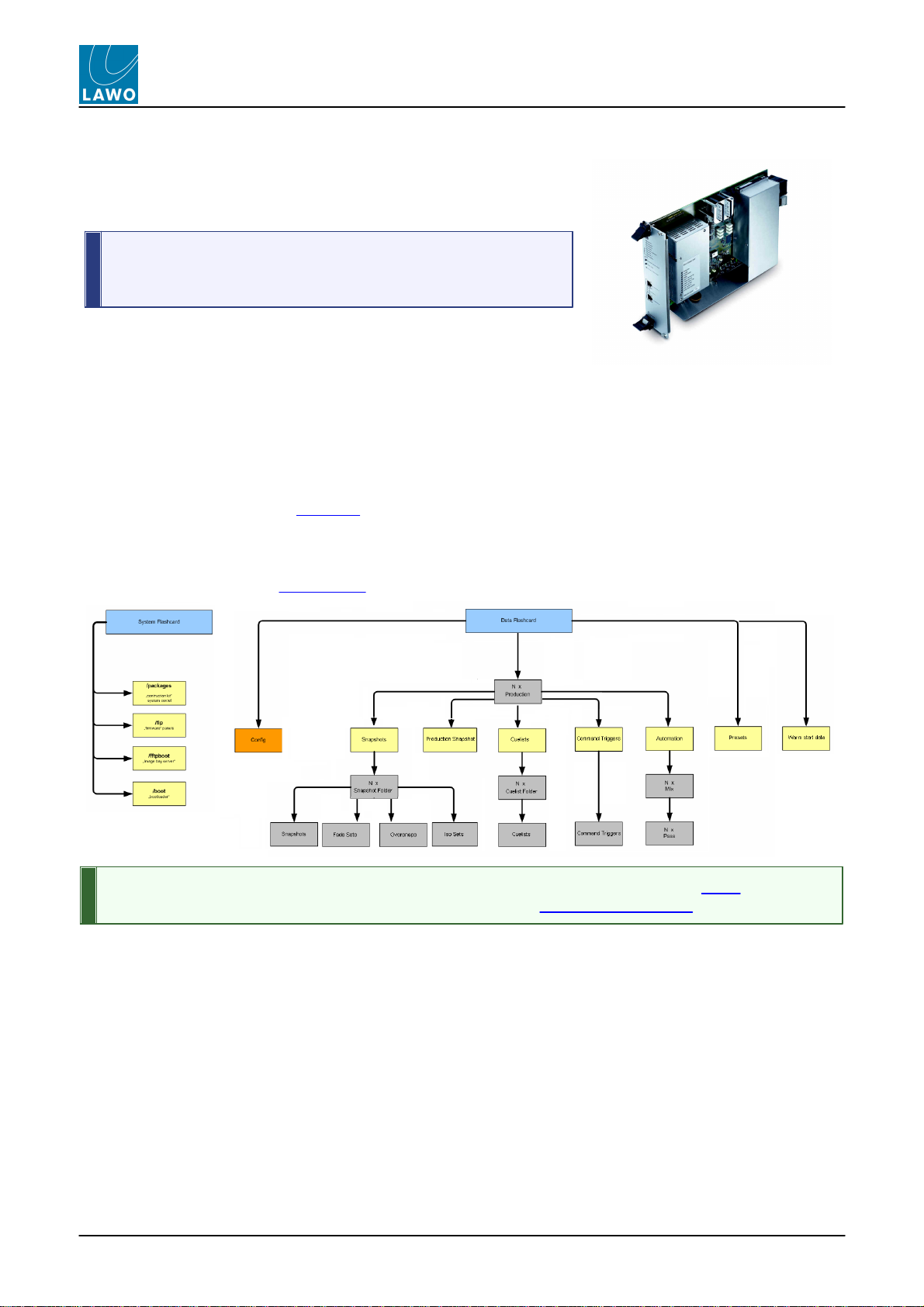

Two flash cards are used to store the application software (System Flashcard) and user data (Data Flashcard)

separately. You can create a backup copy of the flashcards so that they can be replaced if necessary.

During operation, any errors generated by the control system are stored in the message logfile. This can be

copied to USB via the File display, or monitored remotely via the Web Browser Interface.

Table of contents

Other LAWO Recording Equipment manuals