Page6of14 740100-00(5)

3. WIRING (continued)

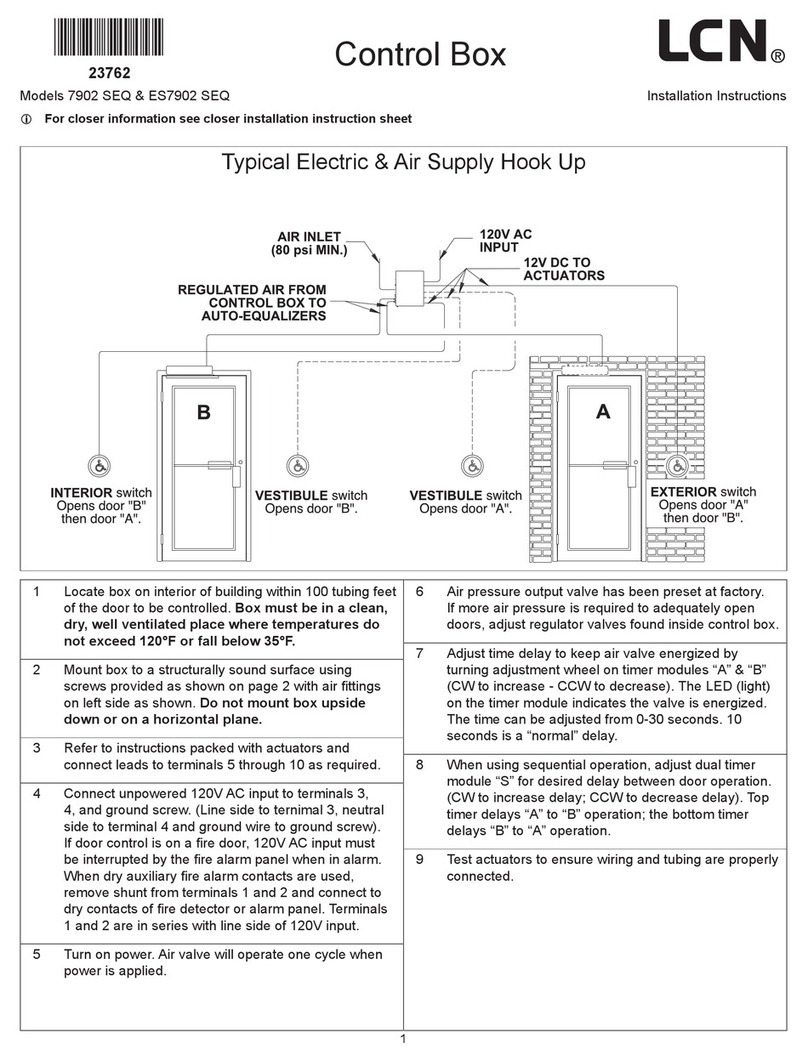

Figure 3-5

Black, 24 VAC

Red, 24 VAC

White, Activate

Green,Ground

Black, 24 VAC

Red, 24 VAC

White,Slowdown

Green,Ground

Black, 24 VAC

Red, 24 VAC

White, Activate

Green,Ground

Black, 24 VAC

White, 24 VAC

Yellow, Activate

Gray, Ground

Black, 24 VAC

White, 24 VAC

Yellow, Activate

Gray, Ground

Blue, Carpet Safety

Gray, Ground

Yellow, Activate

Violet,Slowdown

Orange

Black

Red

Green

Black

Bodyguard

JST-type

connector

ToDMSS

(master;

safety side)

ToDMSS

(master;

approach side)

ToDMSS

(companion;

safety side)

ToDMSS

(companion;

approach side)

To existing cable

710057 (old part

No. 81276)

To 3-position

switch (if used)

To motor cable of

companion operator

(use only for second

door of simultaneous

pair of doors)

To motor cable of

master operator

(always use for

single door)

Bodyguard cable

to Bodyguard

sensor

Cable

761468

Cable

761464

Cable

761464

Cable

761469

Cable

761465 To locking device

(see page 7 for

sample wiring)

Cable

761466

Cable

761463

Retrofit

only

If used

If used

If used

If used

If used

If used

If used

If used

If used

Activate: Initiates a door opening cycle

Bodyguard (master; safety side): Prevents

door from opening; holds open door in open

position (uses door state data from control box

to ignore door movement while opening/closing)

DMSS (master; safety side): Preventsdoorfrom

opening, and slows an opening door

Activate: Initiates a door opening cycle

(operates identically to P6 and is provided as

a convenience if 2 activations are used)

DMSS (master;approachside):Initiatesadoor

opening cycle if activated while door is closing

AC Input: 120 VAC

Companion Motor Power: Companion motor

power (use only for second door of simultaneous

pair or independent pair of doors)

Master Motor Power: Master motor

power (use for single door)

3-Position Switch: OFF, AUTO, HOLD

Locking Interface: Power output and relay

contacts for locking devices; Power Boost

disable input

Breakaway: Disables operator inputs when

Breakaway switch is active

DMSS (companion; safety side): Prevents door

from opening, and slows an opening door

DMSS (companion; approach side): Initiates a

dooropeningcycleifactivatedwhiledoorisclosing

Retrofit Accessories: Accesses older model

Activate, Slow/Stop, and Carpet Safety inputs

P1

P2

P3

P4

P5

P6

P7

P8

P10

P5

LOGIC BOARDPOWER BOARD

To normally closed

Breakaway switch

or jumper 81269

White, 24 VAC

White, 24 VAC

Black, Hot AC

White, Neutral AC

Green,Earth Ground To 120 VAC

Black, 24 VAC

Red, 24 VAC

White,Slowdown

Green,Ground

DMSS

harness

761467

Safety

Approach

Safety

Approach

SafetyApproach SafetyApproach

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

on-board

connector

permanent

connections permanent

connections permanent

connections

permanent

connections

DMSS

harness

761467

Activate cable

To normallyopenActivatecontacts

Activate cable

To normallyopenActivatecontacts

Usedonly forpowered activationdevice

Usedonly forpowered activationdevice

Blue, Power Boost disable

Black, Ground

Violet, Relay NO

Gray, Relay COM

Brown, Relay NC

Green, 5 V

To normally open

Power Boost

disable contacts

Ground