Arrow Board Operators Manual V1.2 Page 8 of 12

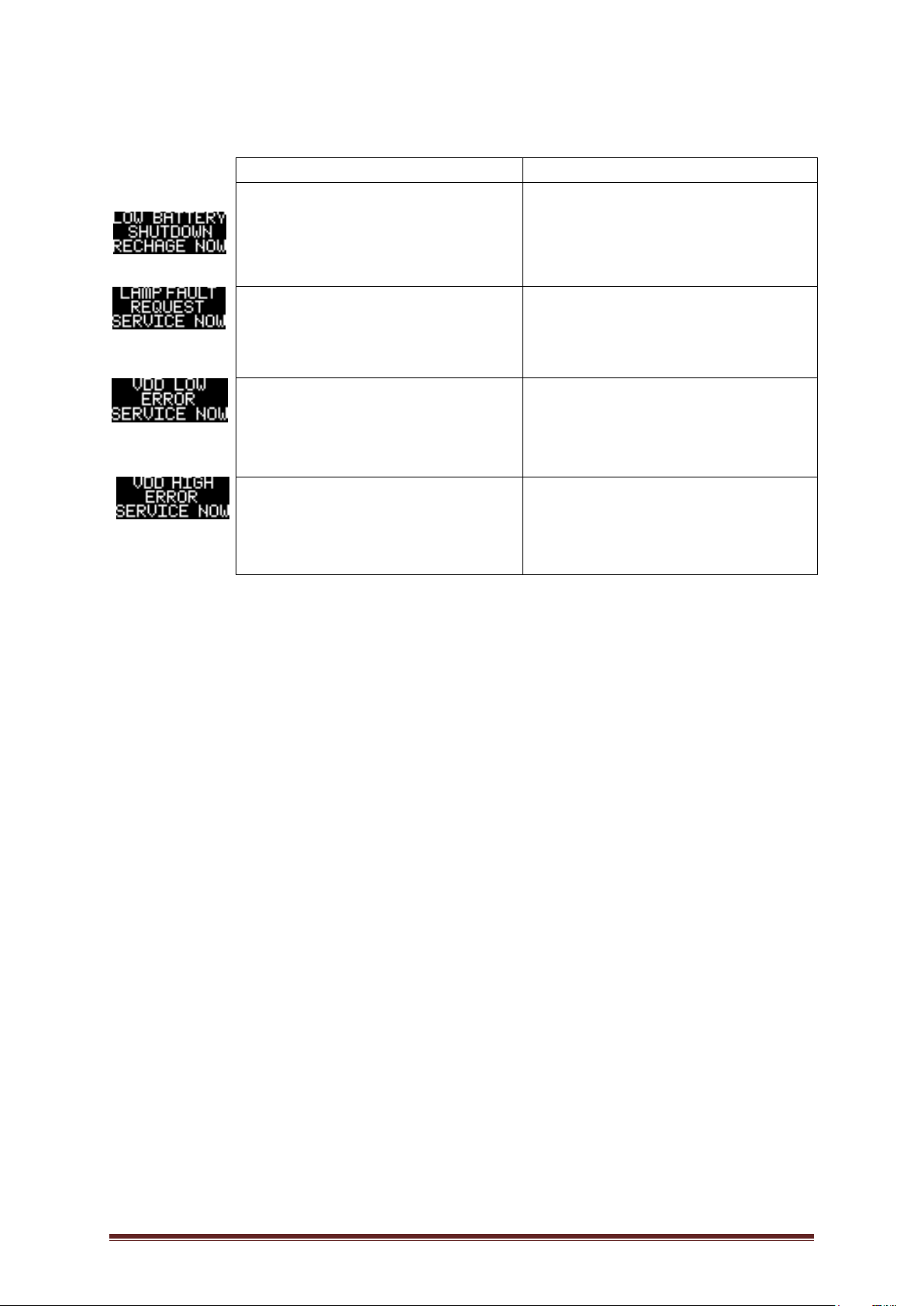

At a voltage drop of 11 volts or less, the system will enter the non-directional warning state

(mode D) indicated on both the sign and the AC4S controller.

At a further voltage drop to 10.4 volts the lamp modules will cease to illuminate completely.

(System enters low voltage shut down) until power is restored to 11.6 volts or above, when

the sign will again turn on and resume normal function.

The current used by the Arrow Board lamps is constantly monitored by a microcontroller on

the Arrow Board computer, if the current is detected to be outside the range of normal

operation, an error is generated and the user is informed on the AC4S controller and the

Arrow Board is shut down.

Troubleshooting

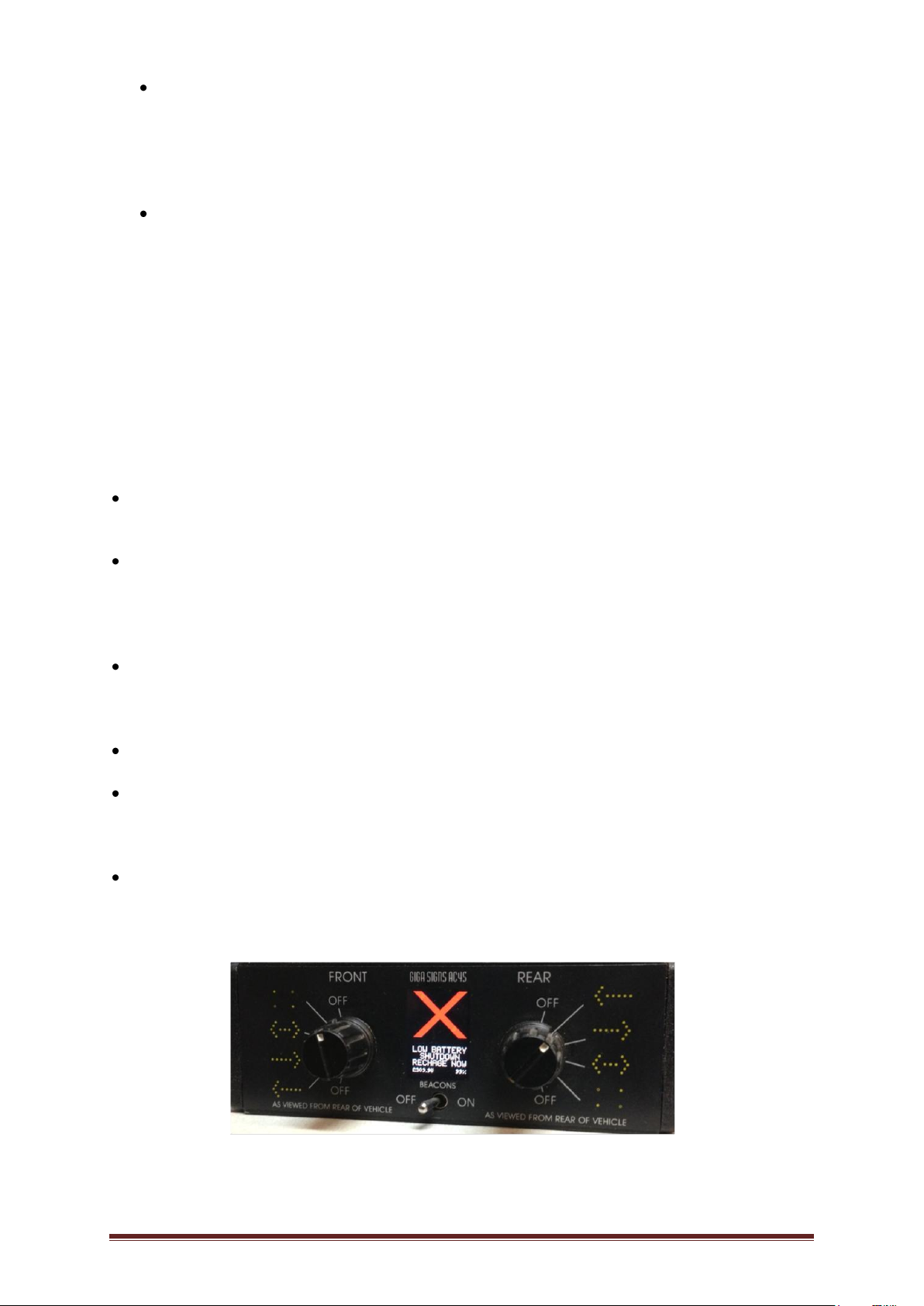

The AC4S Arrow Controller and Arrow Board are similar in operation to a computer network. The

control switches on the Arrow Controller are the master controls and communicate with the

computer in the Arrow board, which in turn responds to given commands. The unit also has a light

sensor mounted at the bottom of the Arrow Board

If the LED display on the controller does not light, check the isolator switch to ensure it is in the

ON or RESET position.

In the event of a failure of any kind, the sign will enter an error state as indicated by a large red X

on the controller screen and the sign will stop operating.

Note: No change of mode will take place to the flashing of the sign, it will stop.

If the unit fails to operate, first check that the Isolator is switched ON (RESET), this isolator is also

a circuit breaker and will automatically switch off, should the wiring to the Arrow Board be

damaged, or there is a failure in one of the Arrow Board modules.

To reset the system, switch the isolator to OFF, wait 10 seconds and turn ON (RESET).

The system automatically dims the lamps in response to a light sensor mounted at the bottom of

the Arrow Board, if the lamps appear dull during daylight hours; clean the light sensor with a

damp cloth.

In the case where one or more of the lamp units fail to light as normal, or if any of the lamps

appear as unusually bright or dim, first check the lamp units are clean and that the apparent

difference is not due to dirt on the LEDs or an obstruction in the shroud.