7 v3.21

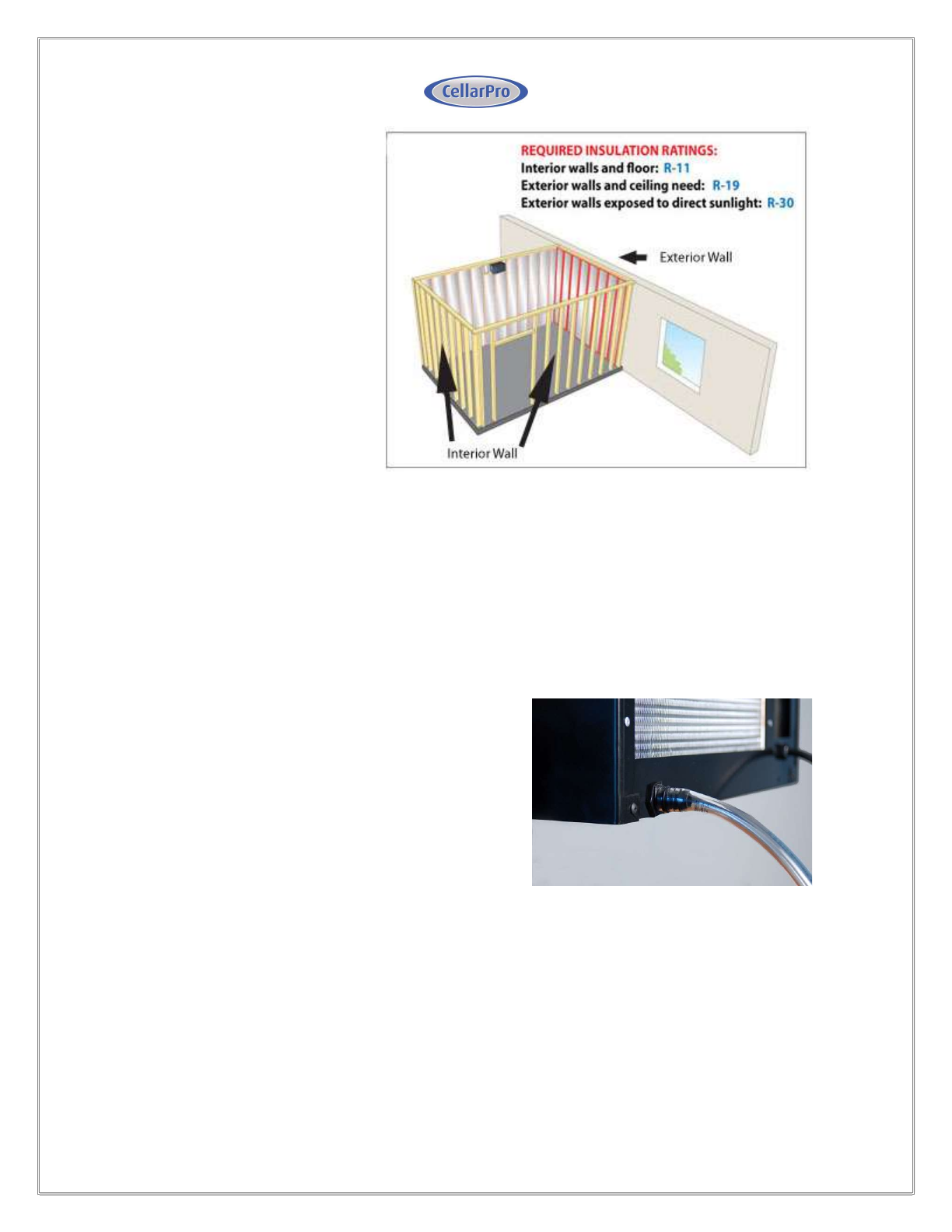

Interior walls and floor

should have a minimum of

R-11 insulation, and a vapor

barrier on the warm side of

the insulation. The ceiling

should have a minimum of

R-19 insulation and a vapor

barrier on the warm side of

the insulation. Doors also

should be insulated and

tightly sealed with weather

stripping around the

perimeter of the door.

Surface-mounted fixtures

are recommended over

recessed lighting, which can

allow air to leak into the

cellar. Please note: The R-values above are the MINIMUM recommended amounts of

insulation. It is advisable to use as much insulation as possible inside your walls,

ceiling and floor. All walls, joints, doors and windows, electrical outlets and/or

switches, pipes, vents and light fixtures should be sealed to prevent ambient air and

moisture from infiltrating into the cellar.

If the cellar is not well sealed, the cooling unit will build up excess condensation that

eventually may damage the internal components and shorten the life of the cooling

unit, and may cause water to leak from the cooling unit.

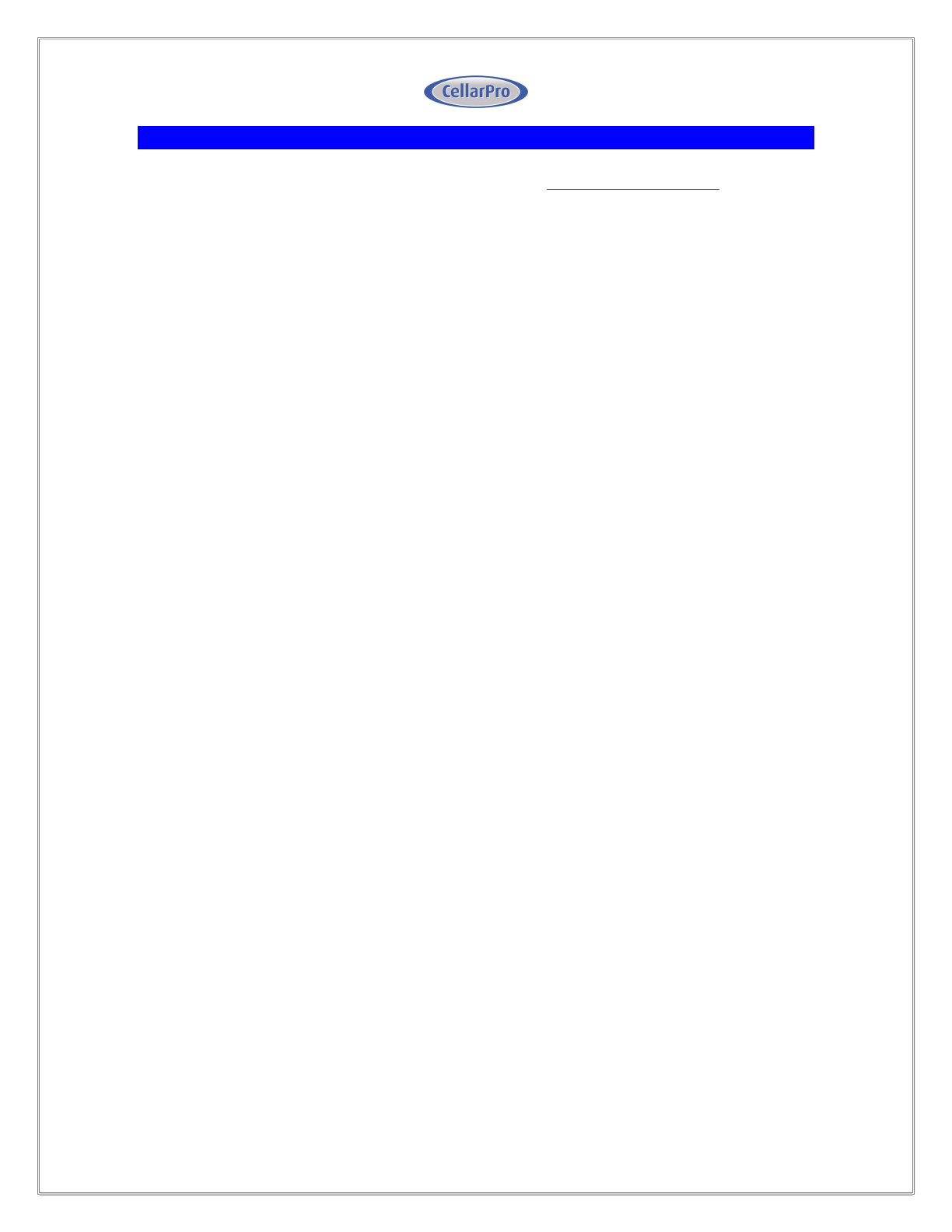

We offer 2 Condensate Drain Line options for

cooling units that will be installed in wine cellars

(as opposed to wine cabinets.) The REAR drain

line configuration includes a fitting and

condensate tube at the rear of the cooling unit

for excess condensate to flow from the rear of

the unit outside the cellar. The BOTTOM drain

line configuration includes a custom hole, a

barbed fitting and a condensate tube at the

bottom of the cooling unit for excess condensate

to flow from the bottom of the unit inside the cellar.

Our REAR drain line comes with the fitting installed in the rear of the cooling unit. Our

BOTTOM drain line requires installation of the fitting. To install, apply pipe joint sealant

(included) to the male threads of the barbed fitting, then hand-tighten the fitting into

the threaded drain line hole. Do not force – if cross threaded, back out and realign.

Finish by tightening the fitting with a wrench.