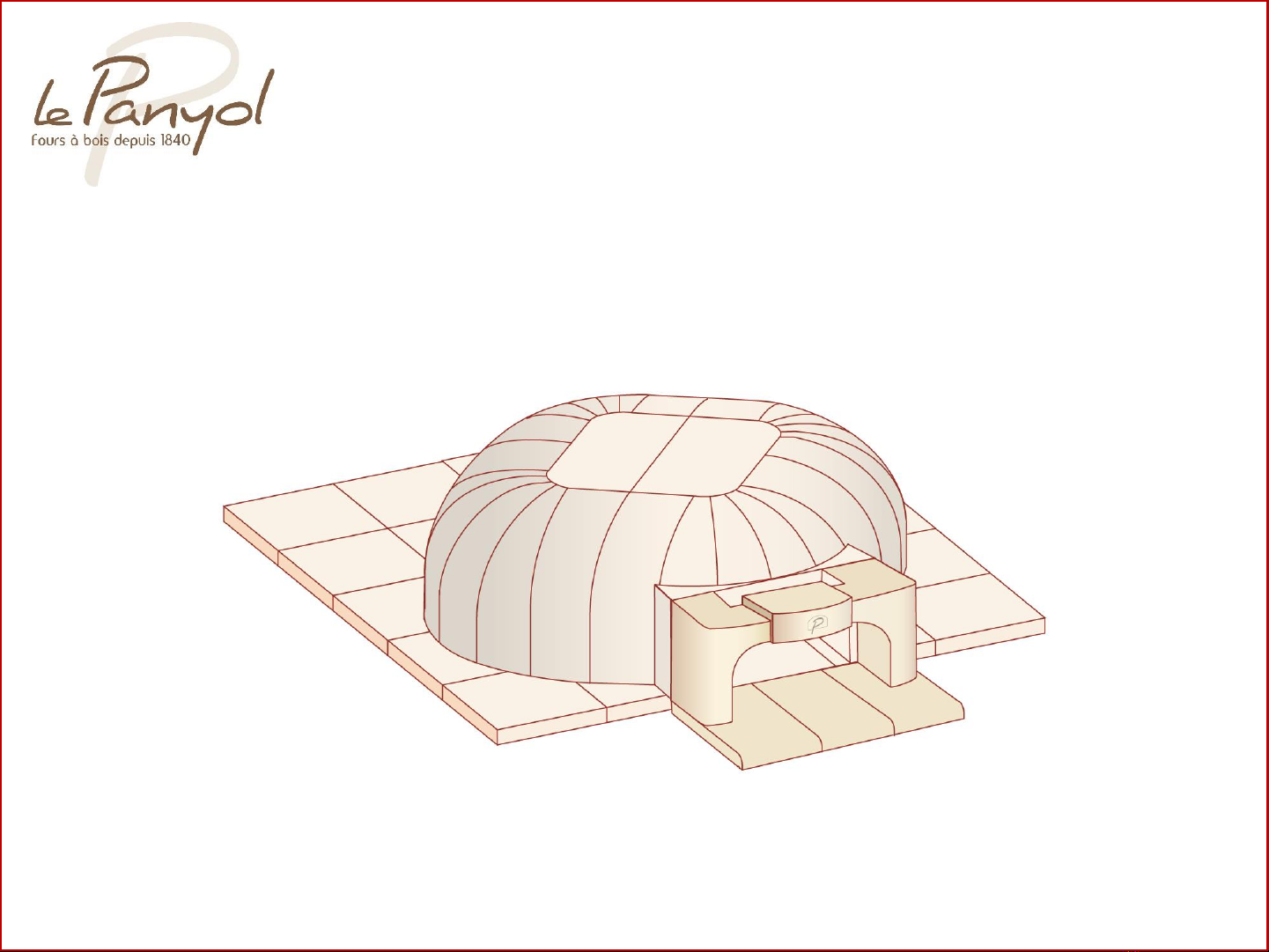

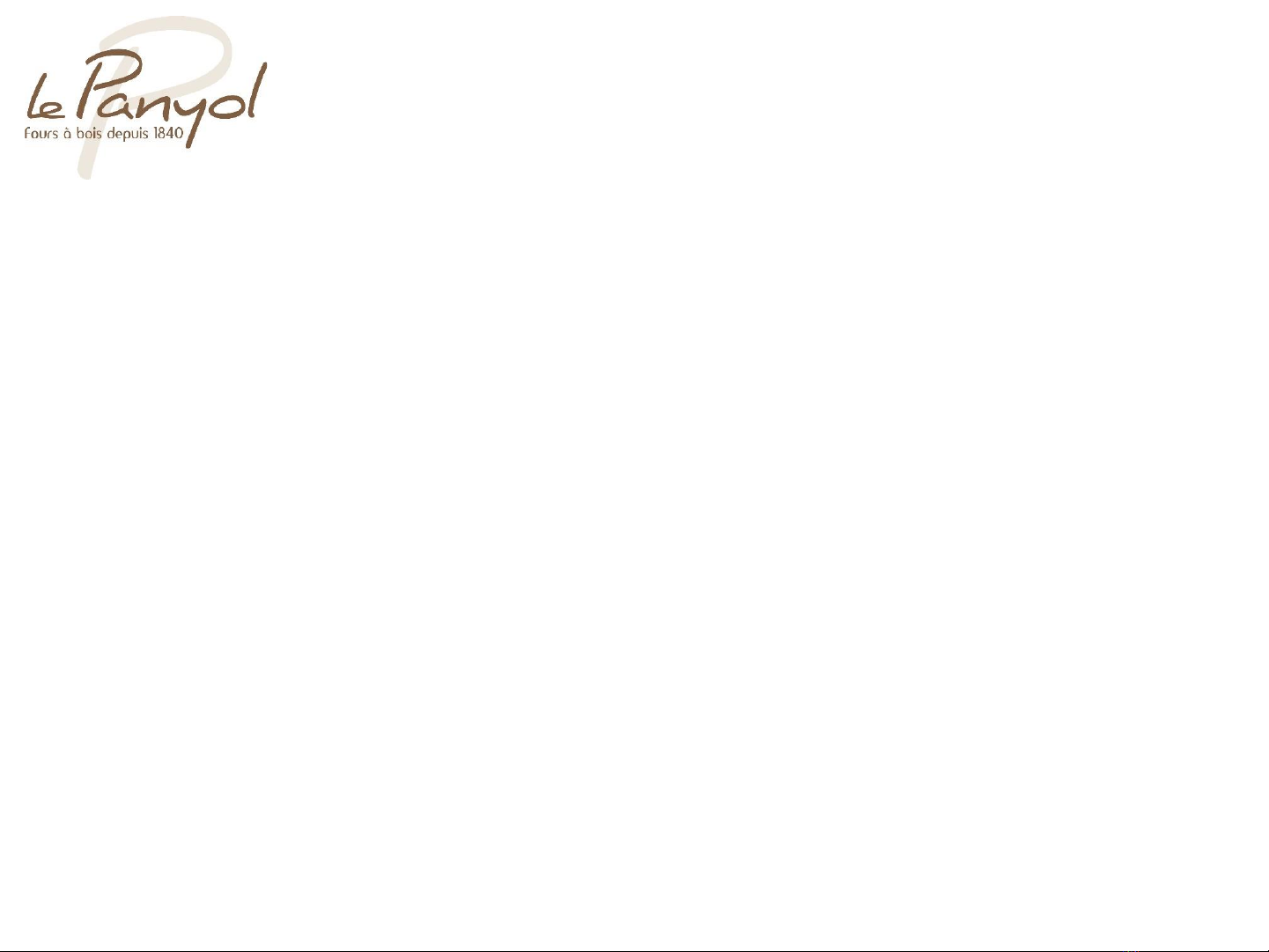

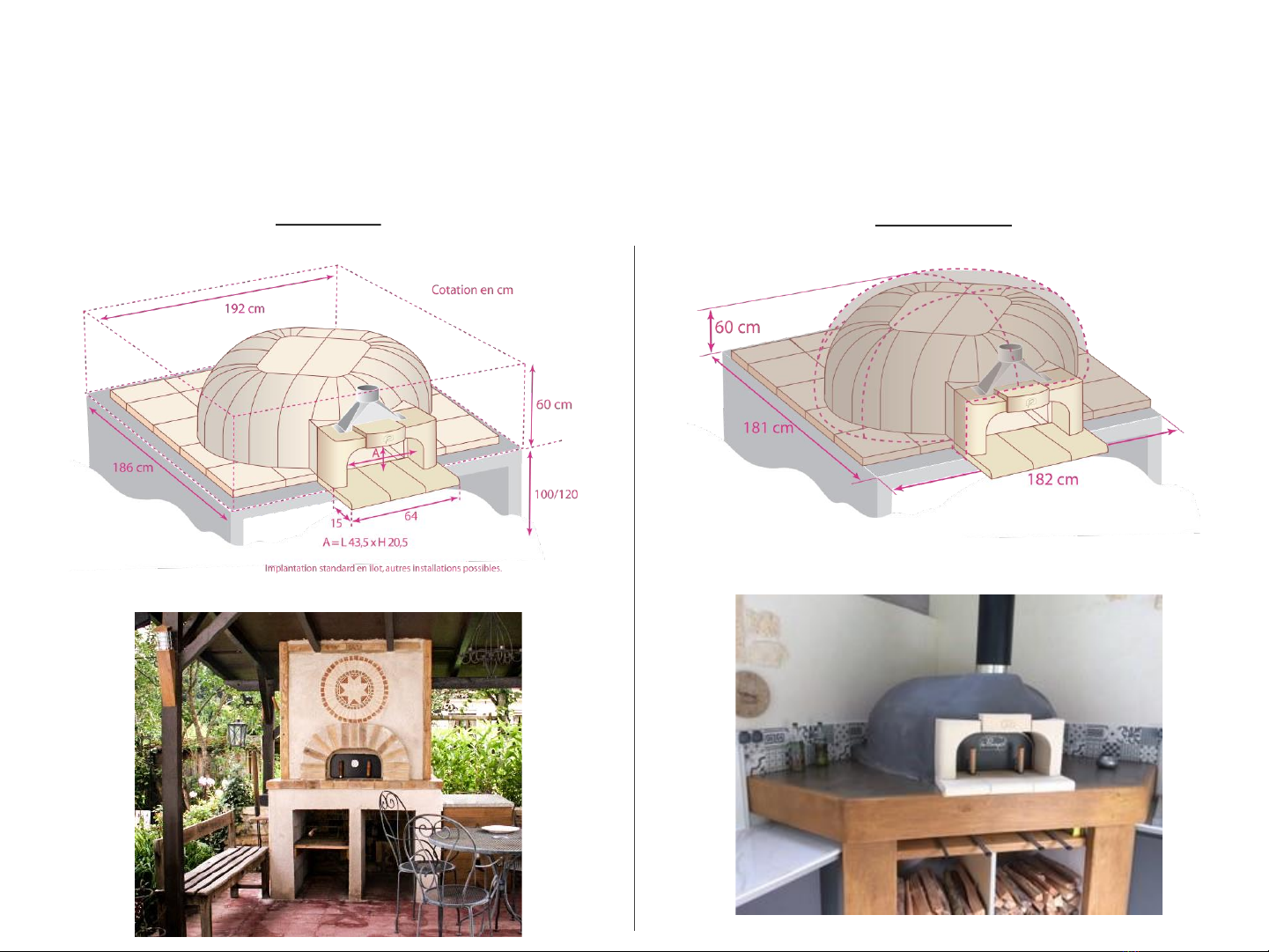

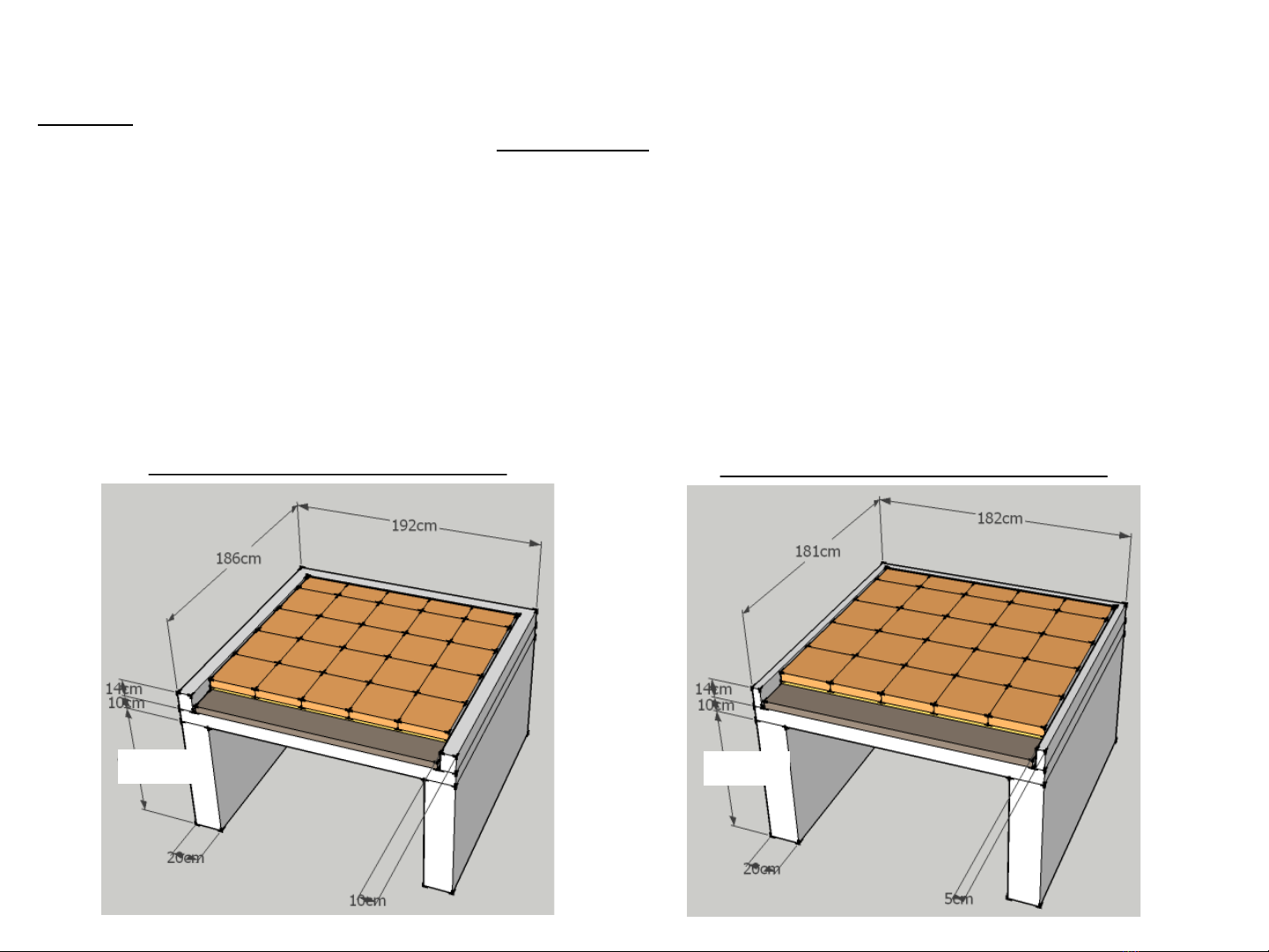

Before you start to assemble the oven, you’ll need to decide where you’re going to place it and work out exactly how much

space you’ll need to install it.

Check in particular that the floor can bear the weight of the finished oven (base + oven + insulation + surround + roof). The floor

must be flat and should not subside under the weight of the construction.

The oven may be installed indoors or outdoors, stand-alone or incorporated into an existing building, near the pool, under a

veranda or in the kitchen. A wide range of installations are possible. See our “Gallery” page on our website or ask the retailer in

your region.

Outdoor Installation

The Le Panyol oven must be protected against bad weather by a roof wide enough to prevent the oven and hearth tiles from

getting wet. It must be kept dry in winter as, if it absorbs water, frost would make it unusable. If the oven is stand-alone, the

pipe must be approximately 1m long. However, if the oven is backed on to a wall or built into the home, the pipe must be long

enough to go 40cm beyond the roof ridge (in accordance with DTU standard 24.1).

Indoor Installation

The Le Panyol oven must be connected to an existing or future-build chimney pipe, in accordance with DTU standard 24.1

(Unified Technical Document). Do not connect more than one apparatus to the same chimney pipe.

The pipe should be:

•180 mm in diameter (the stainless steel smoke adaptor supplied with the oven is 180mm in diameter)

•Made up of a maximum of 2 x 45° bends

•Removable

•With a double skin if an indoor installation

To prevent moisture and rainwater from getting into the pipe, you’ll need to fit a rain cap on the top of the stack.

STEP 1 : Choosing a site