03.5 DMX channels - subject to change (The latest version of DMX channels appendix are on the websites - www. leaderlight.eu)

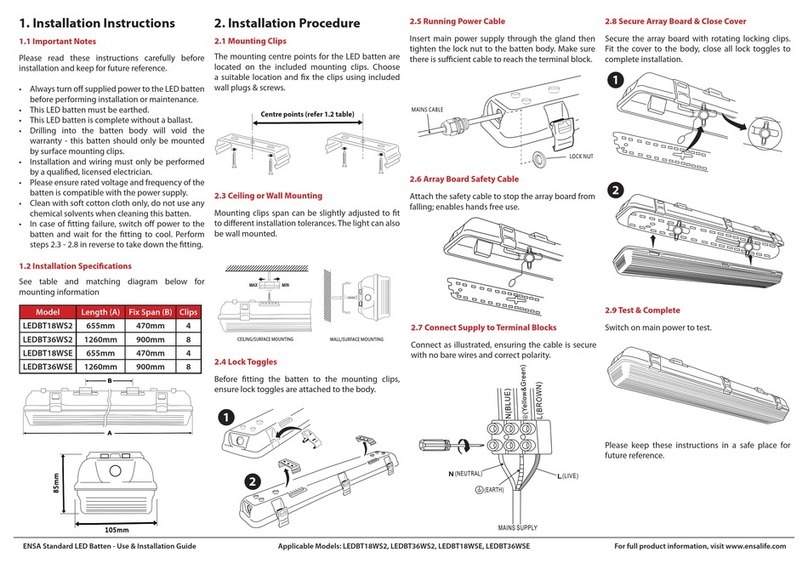

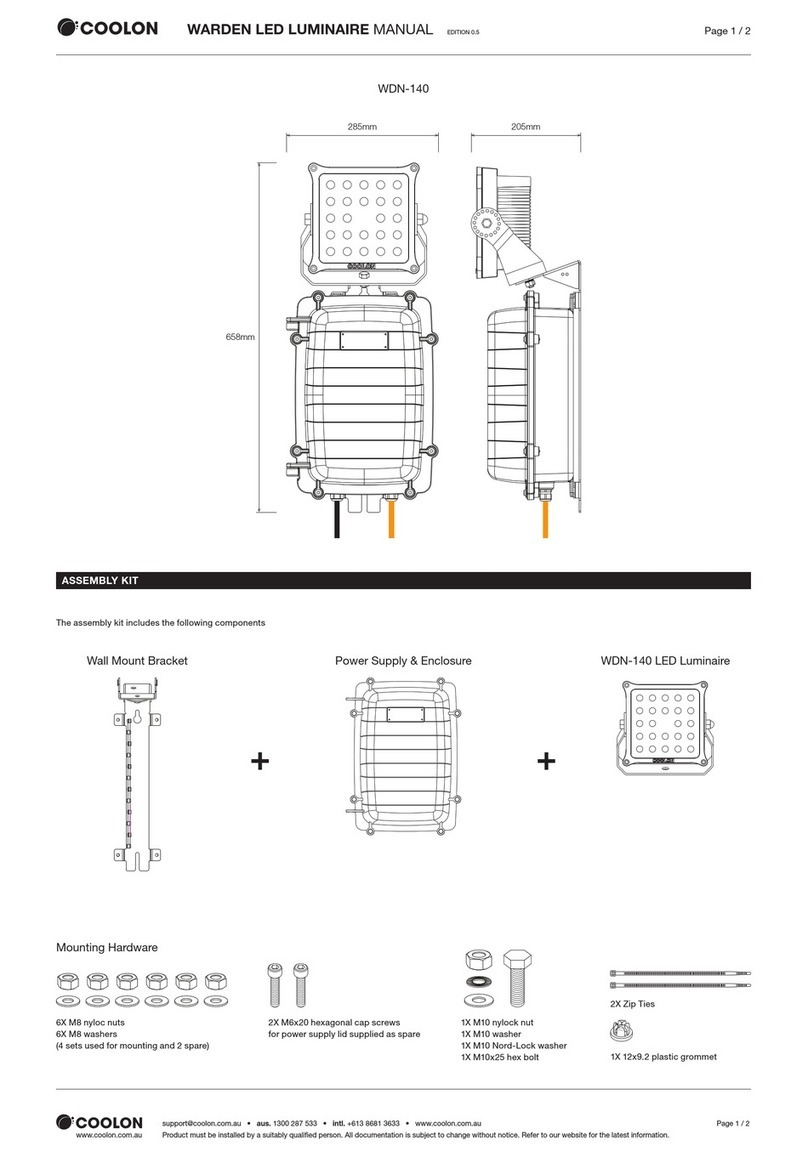

DMX channels and DIP Switch:

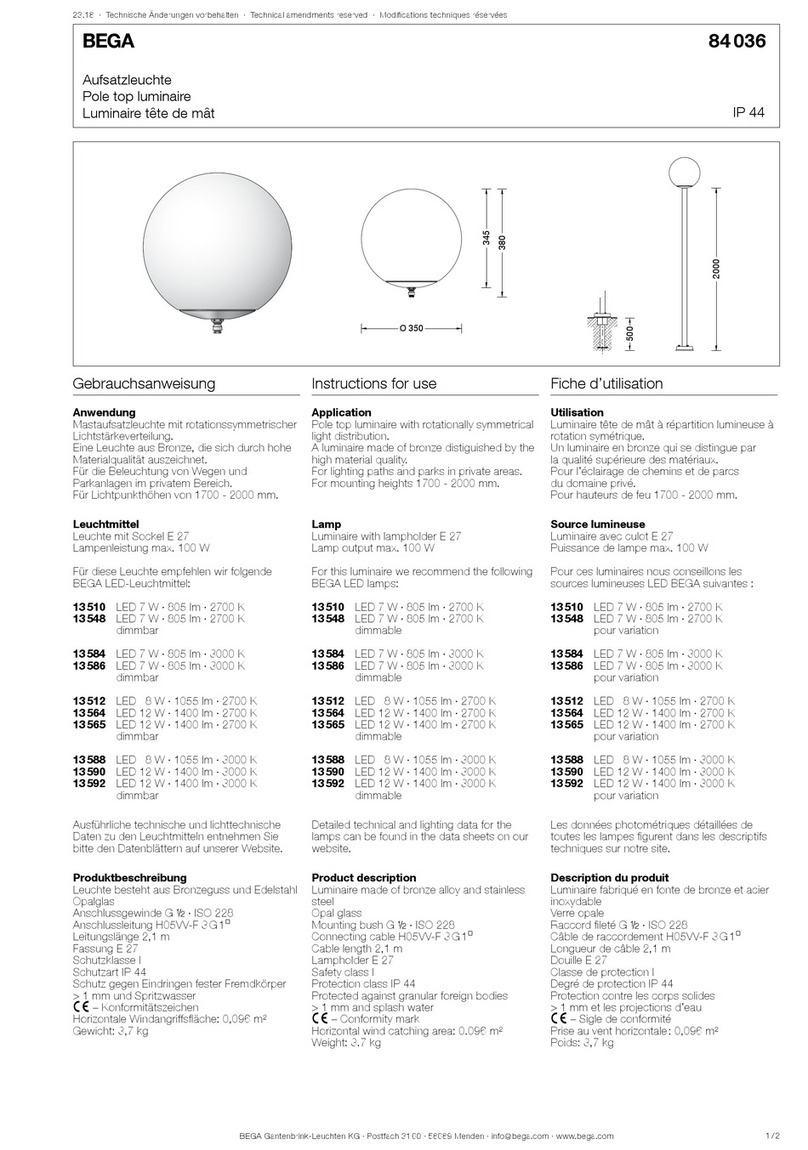

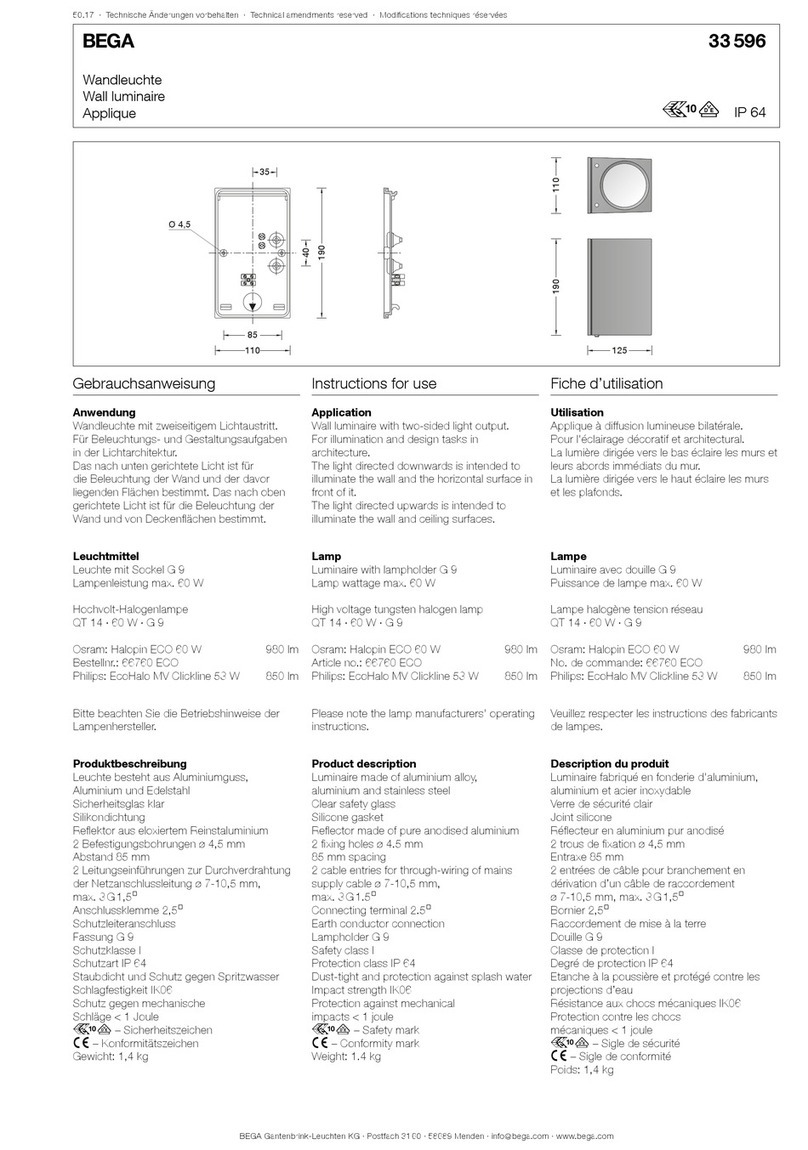

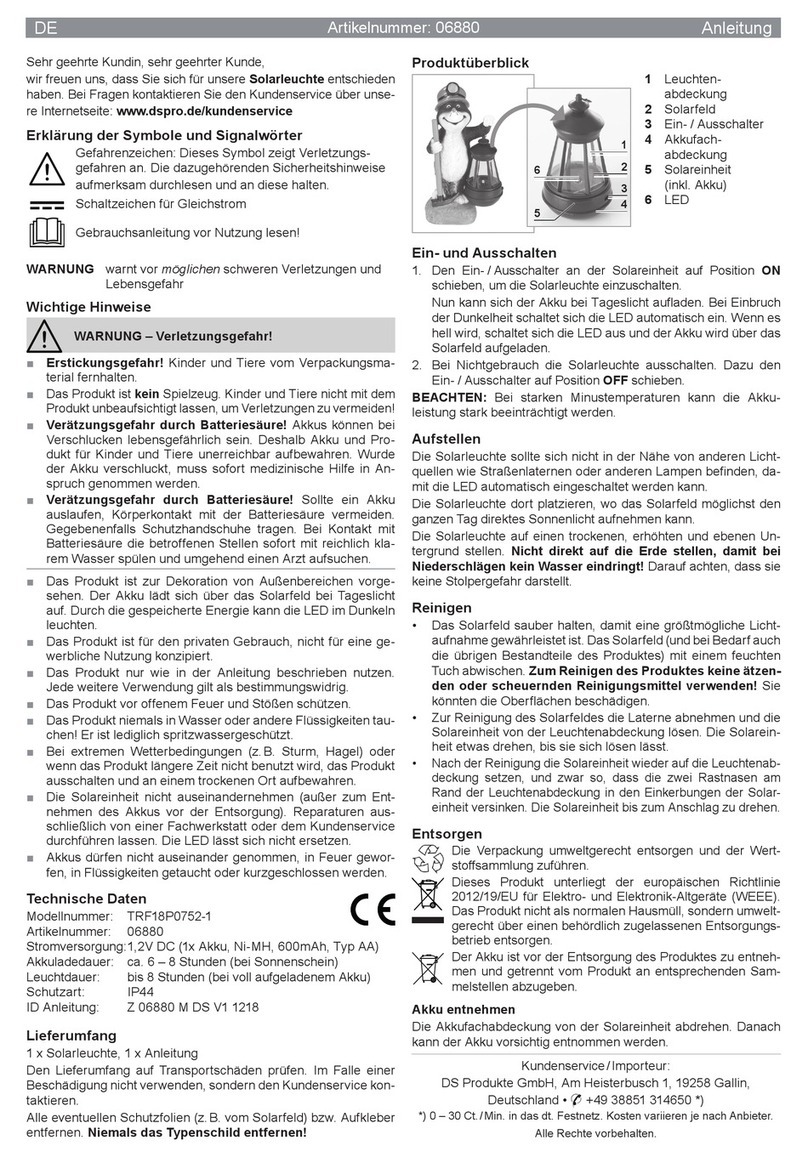

Order code Product name

LL35 070 LL PRO WASH RGBAW 200 FIX 25° ** IP65

LL35 090 LL PRO WASH RGBAW 600 FIX 25° ** IP65

LL35 100 LL PRO WASH AW 200 FIX 25° ** IP65

LL35 120 LL PRO WASH AW 600 FIX 25° ** IP65

Accessories:

LL37 910 LL BARNDOOR PRO WASH 600

** Optional 10°, 40°, EL (Eliptical 15°x90°), AS (Asymetrical) on request.

05 MAINTENANCE

To tackle all Safety Information- 01!

Damage caused by inadequate cleaning or maintenance is not coveredby warranty.

Regular cleaning is demand (dust, dirt, ...).

Maintenance policy:

Unplug mains before maintenance and at least 10 minutes cool off

Appliance do not illegal open or demount

Clean-up dust only from outer surface (for ex. scuttle, diffuser and lenses).

Use vacuum or dumpy duster (warm water)

Before reinstalling to check failure-free state – no wet parts!

-

-

-

-

-

-

-

-

Ch. WASH 600 RGBAW Ch. WASH 600 AW

Mode1: Dip2=Off

1 Red 1,2,3 1 Amber 1,2,3

2 Green 1,2,3 2 White 1,2,3

3Blue 1,2,3 3Master (Dip1=On, Dip4=Off)

4Amber 1,2,3 4 Strobo (Dip1=On, Dip4=Off)

5 White 1,2,3 5

6Master (Dip1=On, Dip4=Off) 6

7Strobo (Dip1=On, Dip4=Off) 7

Mode4: Dip2=On

1 Red 1 1 Amber 1

2 Green 1 2 White 1

3Blue 1 3 Amber 2

4Amber 1 4White 2

5 White 1 5 Amber 3

6 Red 2 6 White 3

7 Green 2 7 Master (Dip1=On, Dip4=Off)

8 Blue 2 8 Strobo (Dip1=On, Dip4=Off)

9Amber 2 9

10 White 2 10

11 Red 3 11

12 Green 3 12

13 Blue 3 13

14 Amber 3 14

15 White 3 15

16 Master (Dip1=On, Dip4=Off) 16

17 Strobo (Dip1=On, Dip4=Off) 17

Extention and control functions:

Dip4=Off, Dip1=Off =>DipBCD: use rotating switch for DMX start

address (RS1-100, RS2-010, RS3-001) from 001 to 511

Dip4=Off, Dip1=On: address+2channel (Master+Strobo)

Dip4=On, Dip1=Off: switch on AutoRun-table functions:

“100“=Prg.0-9, “10“=StepTime, “1“=FadeTime

Dip4=On, Dip1=On: switch all channels on 50% - test

function

Dip2=Off: Mode 1 (5+2ch) Dip2=Off: Mode 1 (2+2ch)

Dip2=On: Mode 4 (15+2ch) Dip2=On: Mode 4 (6+2ch)

Dip3=Off: standard curve

Dip3=On: ultraSoft curve

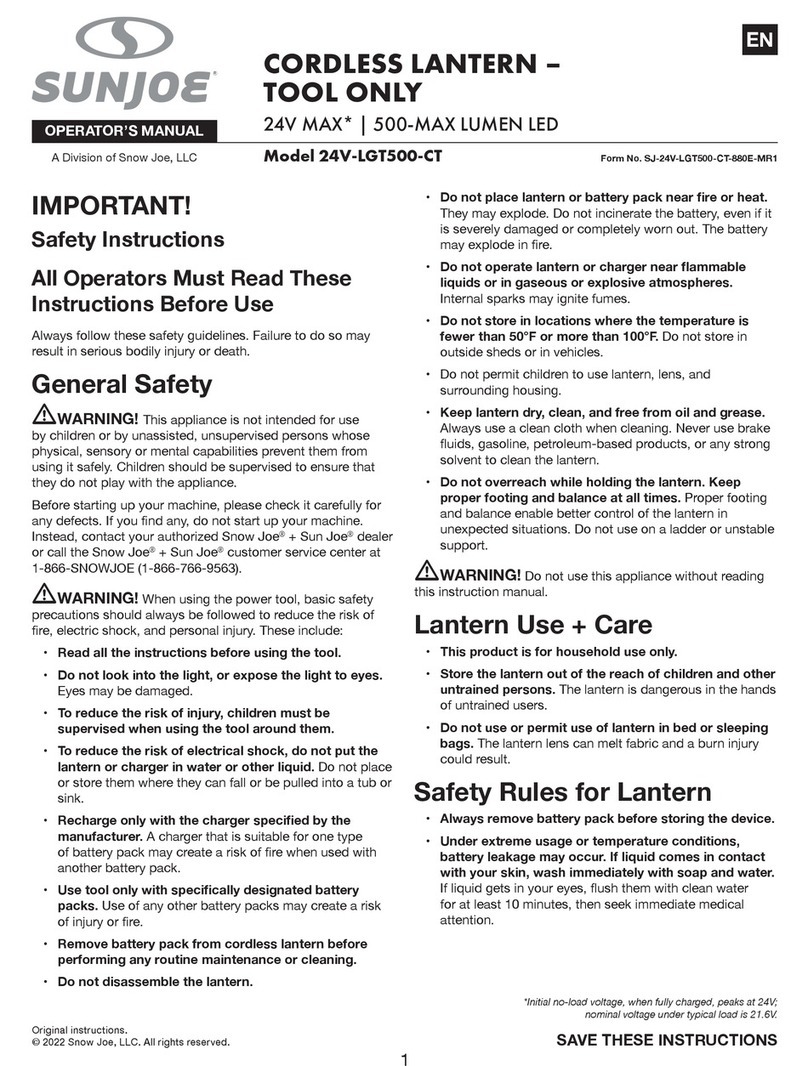

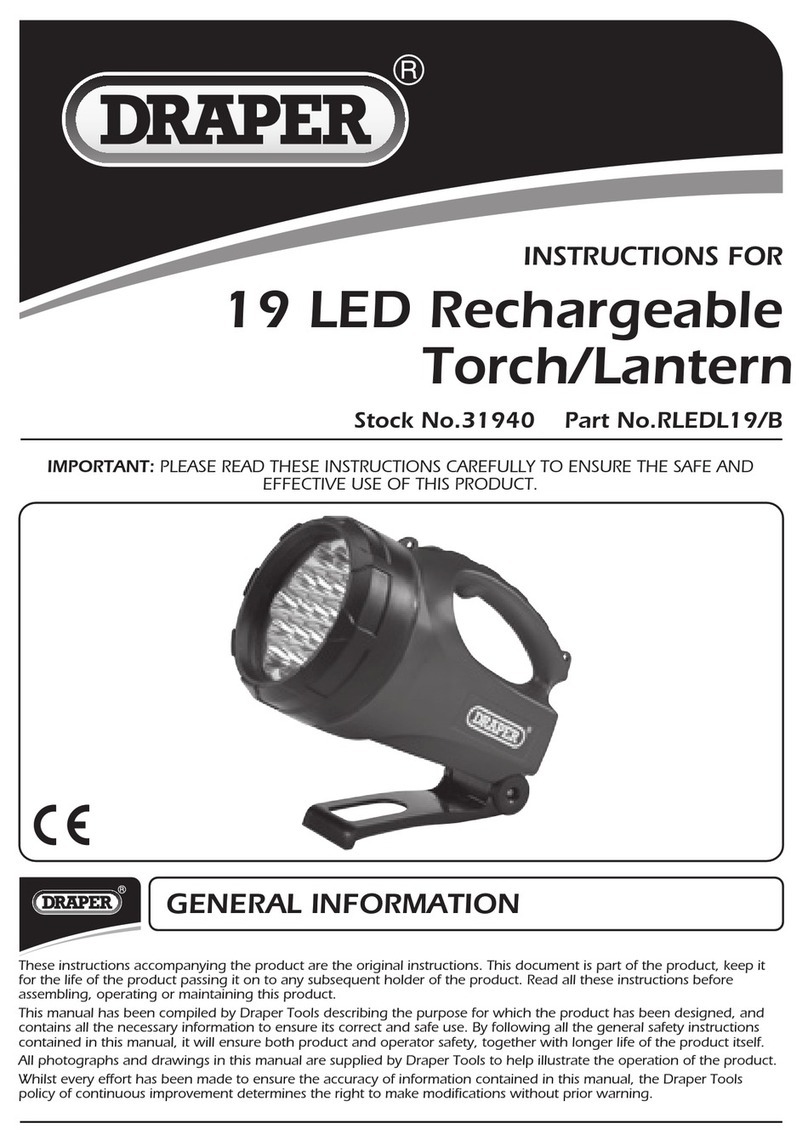

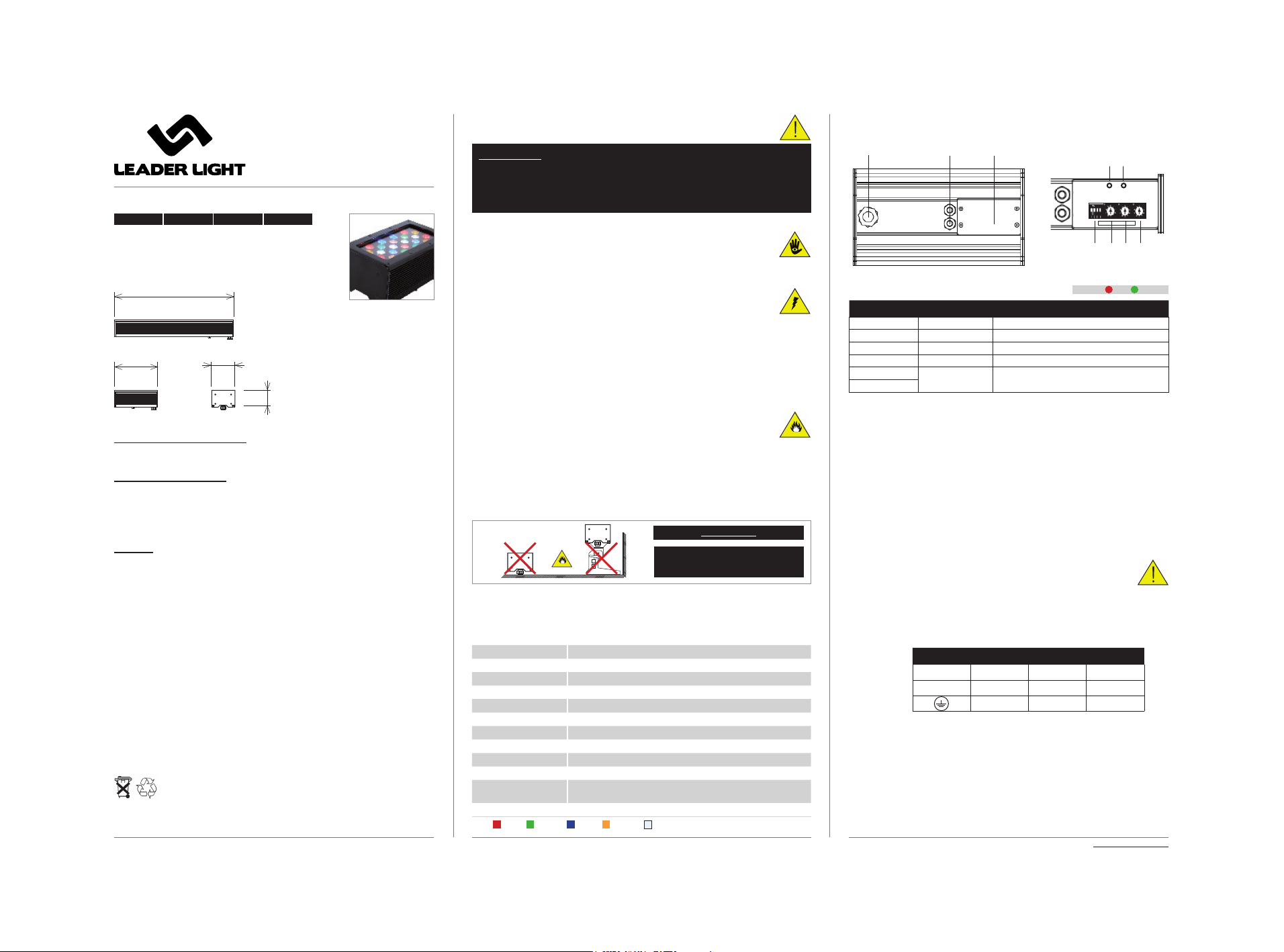

Adjustable bracket

Mechanical mounting of LL PRO WASH IP65 and Adjustable bracket

2.1 Fit the adjustable bracket on the tting and t with srews.

The installation of LL PRO WASH IP65 and Adjustable bracket is easy.

It is not necessary

to open the xture before the mechanical mounting.

90°

AIMING POSSIBILITY

The xture could be aim

to wish position with the

bracket.

2.2 The bracket x to the solid surface with srews (minimal 4pcs).

1.1

minimal.

100mm

Ventilation space 180° free

Minimal mounting distance from surface

Ventilation space 90° free

INSTALLATION SPACE

minimal.

200mm

minimal.

100mm

minimal.

100mm

WARNING!!!

Non-minimum distance and/or non-use

the original brackets is at your own risk!

!!

Ch. WASH 200 RGBAW

Mode1: Dip1=Off

1 Red 1

2 Green 1

3Blue 1

4Amber 1

5 White 1

Mode2: Dip1=On

1 Red 1

2 Green 1

3Blue 1

4Amber 1

5 White 1

6 Master

7Strobo 1-19Hz

Functions DipBCD (rotating switch RS1 - „100“, RS2 - „10“, RS3 - „1“)

DipBCD = 000 = DMX address 001

DipBCD = 001 - 512 = DMX address 001 - 512

DipBCD = 9xx = AutoTest: Fade-Over RGBAW

DipBCD = 8xx = AutoTest: all channels on 50%

DipBCD = 7xx = AutoTest: all channels on 100%

DipBCD = 6xx = AutoTest: White on 100%

Functions Dip (switch Dip1, Dip2, Dip3, Dip4)

Dip1 = On = add + 2 channels (Master + Strobo)

Dip4 = Off = activation Standard curve

Dip4 = On = activation UltraSoft curve

Dip2 = Off, Dip3 = Off = future

Dip2 = Off, Dip3 = On = future

Dip2 = On, Dip3 = Off = future

Dip2 = On, Dip3 = On = future

04 PERNAMENT USE LIMITATIONS FOR HEATING DISSIPATION

Pernament use limitations for heating dissipation of LL PRO WASH RGBAW body

temperature must be less then 55°C

40°C ambient temperature -20% of total power

30°C ambient temperature -10% of total power

20°C ambient temperature -0% of total power

Black version - 30%

Silver or White version - 50%

Example: Then nal pernament value for BLACK colour and 40°C ambient temperature

= -30% -20% = 56% = max 143 ≥ (R + G + B + W +A) / 5

It‘s mean average of power go inside the xture at DMX signal

Example:

black LL PRO WASH: 180 ≥ (R + G + B + W + A) / 5

Silver or White LL PRO WASH: 128 ≥ (R + G + B + W +A) / 5

Value for R or G or B or W or A is 100% = 256 = 8bit levels *** RED 50% = 128 value,

RED 75% = 192 value

Final information we don’t drop down each colour power with temperature control to

get maximum for each colour under total recomMendations , therefore you need setup

limitations from control desk !!!

-