Leagend T86 User manual

Auto Scanner

OBDII/EOBD+BMW

User’s Manual

Item: T86

USER’S MANUAL

OBDII Auto Scanner

2

Table of Contents

1. Safety Precautions and Warnings ..................................................................... 3

2. General Information .......................................................................................... 3

2.1 On-Board Diagnostics (OBD) II ...................................................................... 3

2.2 Diagnostic Trouble Codes (DTCs) .................................................................. 4

2.3 Location of the Data Link Connector (DLC) ................................................... 5

2.4 OBD II Readiness Monitors ............................................................................ 6

2.5 OBD II Monitor Readiness Status ................................................................... 7

2.6 OBD II Definitions ........................................................................................... 8

3. Using the Scan Tool .......................................................................................... 9

3.1 Tool Description .............................................................................................. 9

3.2 Specifications ................................................................................................ 10

3.3 Accessories included .................................................................................... 10

3.4 Power supply ................................................................................................. 10

3.5 Tool setup ...................................................................................................... 11

3.6 Vehicle coverage ........................................................................................... 13

4. Operation ......................................................................................................... 13

4.1 Connection .................................................................................................... 13

4.2 Diagnostic ..................................................................................................... 14

4.2.1 Read Codes ............................................................................................... 15

4.2.2 Erase Codes .............................................................................................. 16

4.2.3 I/M Readiness ............................................................................................ 17

4.2.4 Data Stream ............................................................................................... 18

4.2.5 View Freeze Frame ..................................................................................... 21

4.2.6 O2 sensor test ............................................................................................ 22

4.2.7 On-board monitor test ................................................................................ 24

4.2.8 EVAP System Test ..................................................................................... 25

4.2.9 Vehicle Info ................................................................................................. 25

4.3 BMW Diagnose ............................................................................................. 26

4.4 Code lookup .................................................................................................. 30

4.5 Review History .............................................................................................. 30

4.6 Help ............................................................................................................... 32

5. Warranty and Service ...................................................................................... 33

5.1 Limited One Year Warranty ............................................................................ 33

5.2 Service Procedures ....................................................................................... 33

USER’S MANUAL

OBDII Auto Scanner

3

1. Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or the scan

tool, read this instruction manual first and observe the following safety

precautions at a minimum whenever working on a vehicle:

1. Always perform automotive testing in a safe environment.

2. Wear safety eye protection that meets ANSI standards.

3. Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

4. Operate the vehicle in a well ventilated work area: Exhaust

gases are poisonous.

5. Put blocks in front of the drive wheels and never leave the

vehicle unattended while running tests.

6. Use extreme caution when working around the ignition coil,

distributor cap, ignition wires and spark plugs. These components

create hazardous voltages when the engine is running.

7. Put the transmission in PARK (for automatic transmission) or

NEUTRAL (for manual transmission) and make sure the parking

brake is engaged.

8. Keep a fire extinguisher suitable for gasoline/chemical/electrical

fires nearby.

9. Don't connect or disconnect any test equipment while the ignition

is on or the engine is running.

10. Keep the scan tool dry, clean, free from oil/water or grease. Use

a mild detergent on a clean cloth to clean the outside of the

scan tool, when necessary.

2. General Information

2.1 On-Board Diagnostics (OBD) II

The first generation of On-Board Diagnostics (called OBD I) was

USER’S MANUAL

OBDII Auto Scanner

4

developed by the California Air Resources Board (ARB) and

implemented in 1988 to monitor some of the emission control components

on vehicles. As technology evolved and the desire to improve the On-

Board Diagnostic system increased, a new generation of On-Board

Diagnostic system was developed. This second generation of On-Board

Diagnostic regulations is called "OBD II".

The OBD II system is designed to monitor emission control systems

and key engine components by performing either continuous or periodic

tests of specific components and vehicle conditions. When a problem is

detected, the OBD II system turns on a warning lamp (MIL) on the vehicle

instrument panel to alert the driver typically by the phrase of "Check

Engine" or "Service Engine Soon". The system will also store important

information about the detected malfunction so that a technician can

accurately find and fix the problem. Here below follow three pieces of such

valuable information:

1). If Malfunction Indicator Light (MIL) is commanded 'on' or 'off';

2). Which, if any, Diagnostic Trouble Codes (DTCs) are stored;

3) Readiness Monitor status.

2.2 Diagnostic Trouble Codes (DTCs)

OBD II Diagnostic Trouble Codes are codes that are stored by the on-

board computer diagnostic system in response to a problem found in the

vehicle. These codes identify a particular problem area and are intended

to provide you with a guide as to where a fault might be occurring

within a vehicle. OBD II Diagnostic Trouble Codes consist of a five-digit

alphanumeric code. The first character, a letter, identifies which control

system sets the code. The other four characters, all numbers, provide

additional information on where the DTC originated and the operating

conditions that caused it to set. Here below is an example to illustrate the

structure of digits:

USER’S MANUAL

OBDII Auto Scanner

5

DTC Example

P 0 2 0 2

Systems

B=Body

C=Chassis

P=Powertrain

U=Network

Code Type

Generic (SAE): Manufacturer Specific:

P0, P2, P34-P39 P1, P30-p33

B0, B3 B1, B2

C0, C3 C1, C2

U0, U3. U1, U2

Sub-systems

1= Fuel and Air Metering

2= Fuel and Air Metering

3= Ignition System or Engine Misfire

4= Auxiliary Emission Controls

5= Vehicle Speed Control and

Idle Controls

6= Computer Output Circuits

7= Transmission Controls

8= Transmission Controls

Identifying specific

malfunctioning section

of the systems

2.3 Location of the Data Link Connector (DLC)

The DLC (Data Link Connector or Diagnostic Link Connector) is the

standardized 16-cavity connector where diagnostic scan tools interface

with the vehicle's on-board computer. The DLC is usually located 12

inches from the center of the instrument panel (dash), under or around the

driver's side for most vehicles. If Data Link Connector is not located under

dashboard, a label should be there telling location. For some Asian and

European vehicles, the DLC is located behind the ashtray and the ashtray

must be removed to access the connector. If the DLC cannot be found,

refer to the vehicle's service manual for

the location.

USER’S MANUAL

OBDII Auto Scanner

6

2.4 OBD II Readiness Monitors

An important part of a vehicle's OBD II system is the Readiness

Monitors, which are indicators used to find out if all of the emissions

components have been evaluated by the OBD II system. They are running

periodic tests on specific systems and components to ensure that they are

performing within allowable limits.

Currently, there are eleven OBD II Readiness Monitors (or I/M Monitors)

defined by the U.S. Environmental Protection Agency(EPA). Not all

monitors are supported by all vehicles and the exact number of monitors

in any vehicle depends on the motor vehicle manufacturer's emissions

control strategy.

Continuous Monitors -- Some of the vehicle components or systems

are continuously tested by the vehicle's OBD II system, while others are

tested only under specific vehicle operating conditions. The continuously

monitored components listed below are always ready:

1. Misfire

2. Fuel System

3. Comprehensive Components (CCM)

Once the vehicle is running, the OBD II system is continuously

checking the above components, monitoring key engine sensors, watching

for engine misfire, and monitoring fuel demands.

Non-Continuous Monitors -- Unlike the continuous monitors, many

emissions and engine system components require the vehicle to be

operated under specific conditions before the monitor is ready. These

monitors are termed non-continuous monitors and are listed below:

1). EGR System

2). O2 Sensors

3). Catalyst

4). Evaporative System

USER’S MANUAL

OBDII Auto Scanner

7

5). O2 Sensor Heater

6). Secondary air

7). Heated Catalyst

8). A/C system

2.5 OBD II Monitor Readiness Status

OBD II systems must indicate whether or not the vehicle's PCM's

monitor system has completed testing on each component. Components

that have been tested will be reported as "Ready", or "Complete",

meaning they have been tested by the OBD II system. The purpose

of recording readiness status is to allow inspectors to determine if the

vehicle's OBDII system has tested all the components and/or systems.

The powertrain control module (PCM) sets a monitor to "Ready" or

"Complete" after an appropriate drive cycle has been performed. The

drive cycle that enables a monitor and sets readiness codes to "Ready"

varies for each individual monitor. Once a monitor is set as "Ready" or

"Complete", it will remain in this state. A number of factors, including

erasing of diagnostic trouble codes (DTCs) with a scan tool or a

disconnected battery, can result in Readiness Monitors being set to "Not

Ready". Since the three continuous monitors are constantly evaluating,

they will be reported as "Ready" all of the time. If testing of a particular

supported non-continuous monitor has not been completed, the monitor

status will be reported as "Not Complete" or "Not Ready".

In order for the OBD monitor system to become ready, the vehicle

should be driven under normal operating conditions. These operating

conditions may include a mix of highway driving and stop and go, city type

driving, and at least one overnight-off period. For specific information on

getting your vehicle's OBD monitor system ready, please consult your

vehicle owner's manual.

USER’S MANUAL

OBDII Auto Scanner

8

2.6 OBD II Definitions

Powertrain Control Module (PCM) -- OBDII terminology for the on-board

computer that controls engine and drive train.

Malfunction Indicator Light (MIL) -- Malfunction Indicator Light (Service

Engine Soon, Check Engine) is a term used for the light on the instrument

panel. It is to alert the driver and/or the repair technician that there is a

problem with one or more of vehicle's systems and may cause emissions

to exceed federal standards. If the MIL illuminates with a steady light, it

indicates that a problem has been detected and the vehicle should be

serviced as soon as possible. Under certain conditions, the dashboard

light will blink or flash. This indicates a severe problem and flashing is

intended to discourage vehicle operation. The vehicle onboard diagnostic

system can not turn the MIL off until necessary repairs are completed or

the condition no longer exists.

DTC -- Diagnostic Trouble Codes (DTC) that identify which section of the

emission control system has malfunctioned.

Enabling Criteria --Also termed Enabling Conditions.They are the

vehicle-specific events or conditions that must occur within the engine

before the various monitors will set, or run. Some monitors require the

vehicle to follow a prescribed "drive cycle" routine as part of the enabling

criteria. Drive cycles vary among vehicles and for each monitor in any

particular vehicle.

OBD II Drive Cycle -- A specific mode of vehicle operation that provides

conditions required to set all the readiness monitors applicable to the

vehicle to the "ready" condition. The purpose of completing an OBD II

drive cycle is to force the vehicle to run its onboard diagnostics. Some

form of a drive cycle needs to be performed after DTCs have been erased

from the PCM's memory or after the battery has been disconnected.

Running through a vehicle's complete drive cycle will set the readiness

monitors so that future faults can be detected. Drive cycles vary depending

USER’S MANUAL

OBDII Auto Scanner

9

on the vehicle and the monitor that needs to be reset. For vehicle specific

drive cycle, consult the vehicle's Owner's Manual.

Freeze Frame Data -- When an emissions related fault occurs, the OBD

II system not only sets a code but also records a snapshot of the vehicle

operating parameters to help in identifying the problem. This set of values

is referred to as Freeze Frame Data and may include important engine

parameters such as engine RPM, vehicle speed, air flow, engine load,

fuel pressure, fuel trim value, engine coolant temperature, ignition timing

advance, or closed loop status.

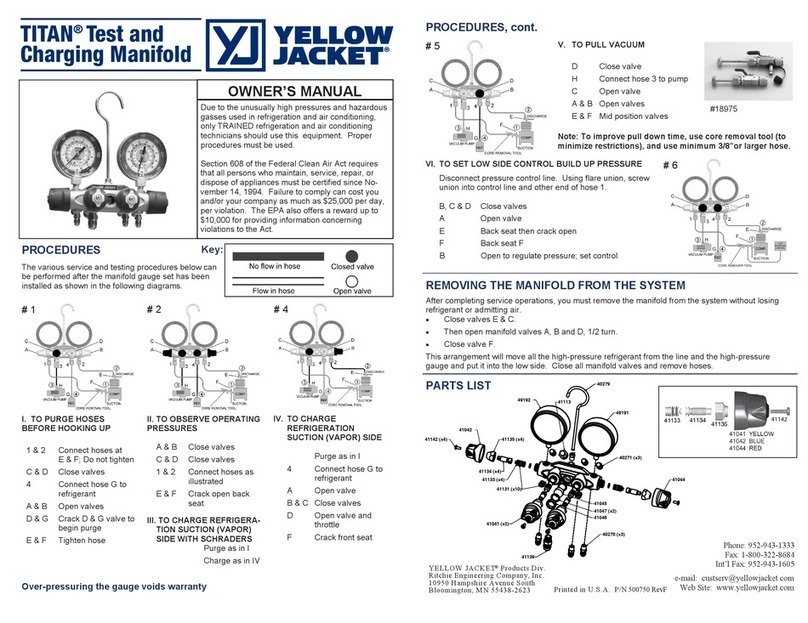

3. Using the Scan Tool

1

2

4

8

6

3

9

7

5

USER’S MANUAL

OBDII Auto Scanner

10

3.2 Specifications

Screen: 2.8" TFT color screen.

Input voltage range: 8~32V

Operating temperature: 32_~122 C

Storage temperature: -4 ~158_ / -20 ~70 C

Outline dimension: 20*8.5*2.8CM

Weight : <17.6 oz (500g)

3.3 Accessories Included

User Manual -- Show the user how to operate the tool.

CD -- Include the software.

USB cable -- Connect to a computer for upgrading online.

3.4 Power supply

The power of the Car scanner is provided via the vehicle Data Link

Connector (DLC). Follow the steps below to power it up:

A. Find DLC on vehicle: A plastic DLC cover may be found for some

vehicles and you need to remove it before plugging the OBDII cable.

B. Plug the connector at the end of OBD II cable to the vehicle.

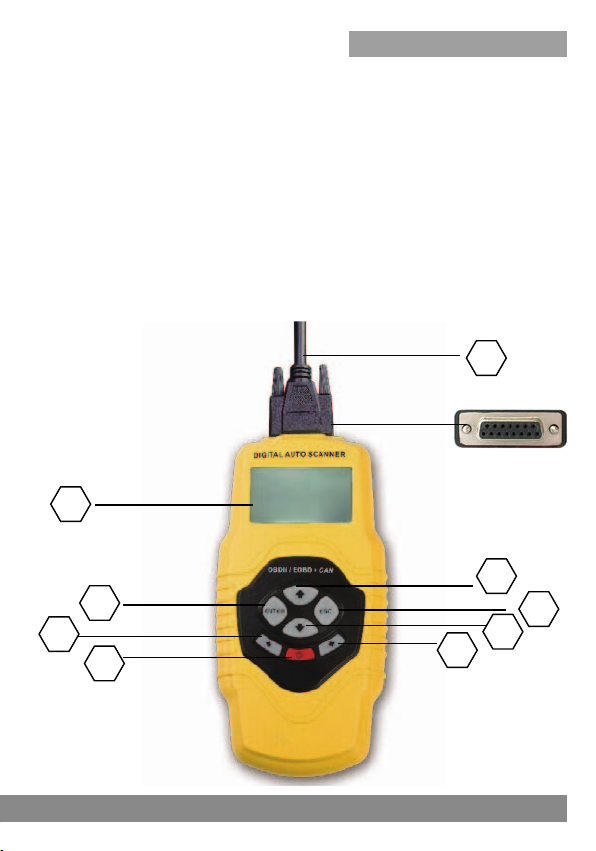

3.1 Tool Description

1. LCD DISPLAY -- Indicates test information.

2. ENTER BUTTON--Confirms a selection (or action) from a menu.

3. ESC BUTTON -- Returns to previous menu.

4/5. RIGHT/LEFT BUTTONs -- Move cursor right or left for selection; Or

turn page up or down when more than one page is displayed.

6/7. UP/DOWN BUTTONs-- Move cursor up or down for selection.

8.POWER SWITCH -- Turns on/off the scan tool when powered by cell

battery; resets the scanner when powered by vehicle battery.

9. OBD II CONNECTOR -- Connects the AUTO SCANNER to the vehicle.

USER’S MANUAL

OBDII Auto Scanner

11

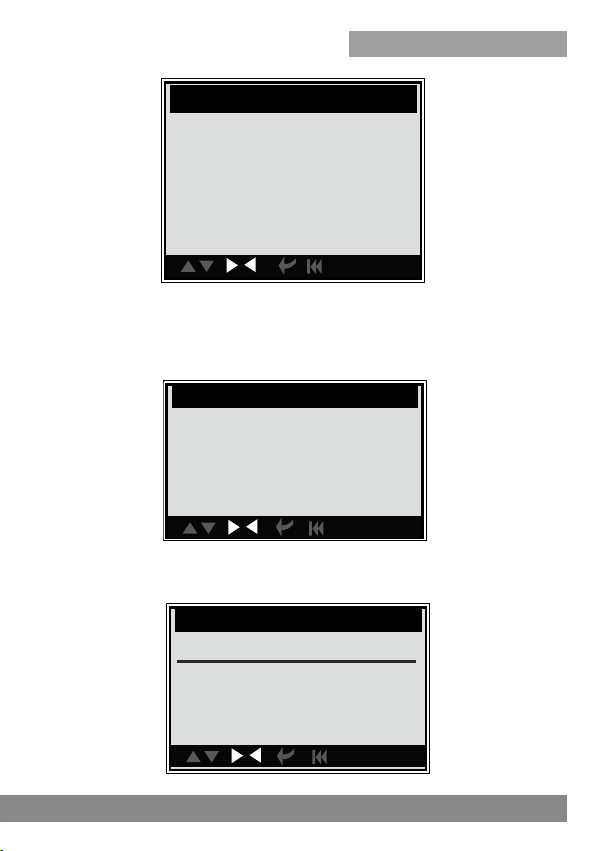

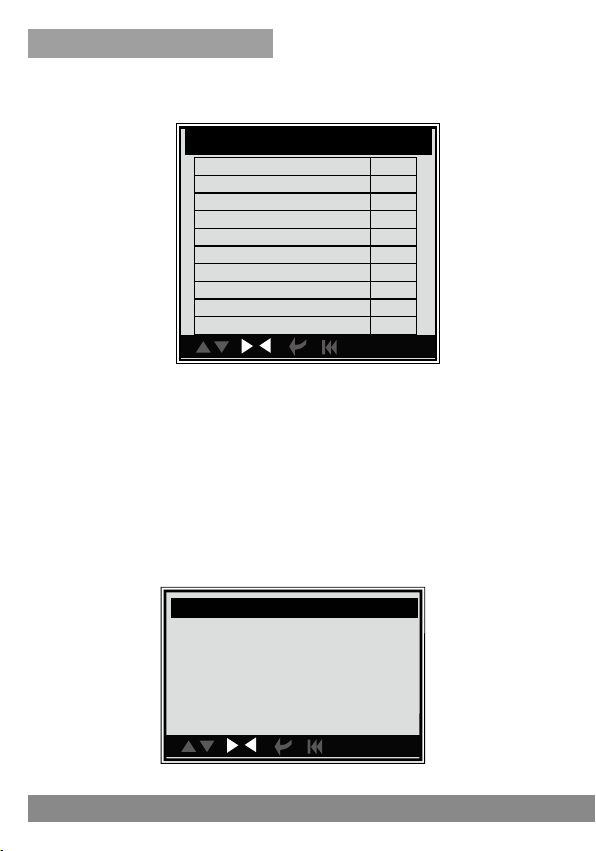

You can press [UP] [DOWN] key to select any language and press [ENTER]

to confirm. The system will convert to the chosen language interface at

once.

2). Unit of measure.

Choose [Unit of measure] and press [ENTER], the screen will display the

interface as shown below:

con.

Tool Setup

Language

Unit of measure

Beeper

Record mode

to make the following adjustments, settings:

1). Select language: Selects desired language.

Choose [Language] and press [ENTER], the screen will display the

interface as shown below:

con.

Language

English

3.5 Tool Setup

Select [Tool Setup] in the Main Menu and press [ENTER], the screen will

display the interface as shown below:

USER’S MANUAL

OBDII Auto Scanner

12

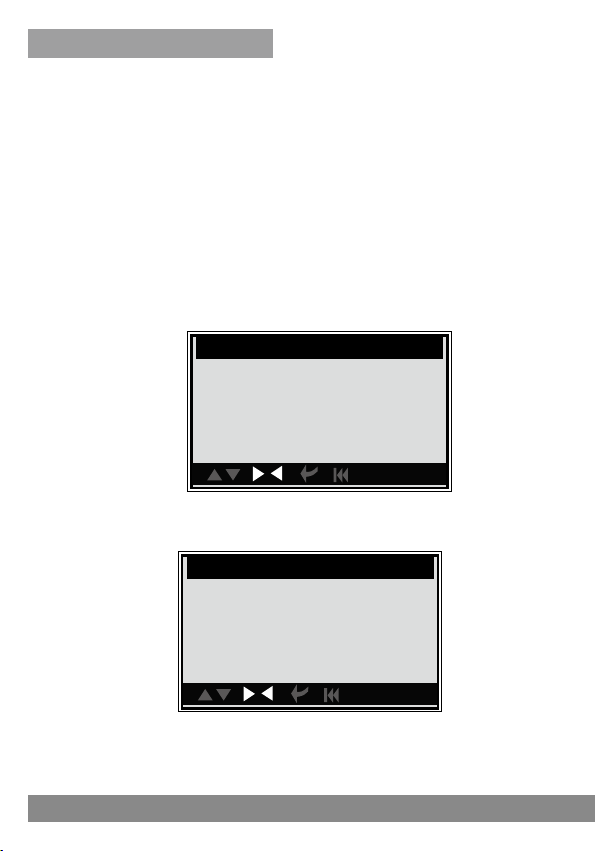

Press [UP] or [DOWN] to select ON/OFF and press [ENTER] to confirm.

4). Record: ON/OFF the Record.

Choose [Record More] and press [ENTER], the screen will display the

interface as shown below:

con.

Record More

ON

con.

Unit of measure

Flow lb/min

Speed mph

Distance miles

Pressure 1 psi

Pressure 2 inHg

Pressure 3 inH20

Pressure 4 inH20

Press [UP] or [DOWN] to select it and press [LEFT] and [RIGHT] to

change, then press [ENTER] to confirm.

3). Beeper: ON/OFF the Beeper.

Choose [Beep] and press [ENTER], the screen will display the interface as

shown below: con.

Beeper

ON

USER’S MANUAL

OBDII Auto Scanner

13

4. OPERATION

4.1 Connection

1). Turn the ignition off.

2). Locate the vehicle

3). Plug the OBDII cable into the vehicle

4). Turn the ignition on. Engine can be off or running.

After finishing, press [ENTER] button to enter Main Menu as following

picture:

3.6 Vehicle Coverage

This model OBDII/EOBD Scanner is specially designed to work with all

OBD II compliant vehicles, including those equipped with next-generation

protocol -- Control Area Network (CAN). It is required by EPA that all 1996

and newer vehicles (cars and light trucks) sold in the world must be OBD

II compliant and this includes all America, Asian and European vehicles.

A small number of 1994 and 1995 model year gasoline vehicles are

OBD II compliant. To verify if a 1994 or 1995 vehicle is OBD II compliant,

check the Vehicle Emissions Control Information (VECI) Label which is

located under the hood or by the radiator of most vehicles. If the vehicle is

OBD II compliant, the label will designate "OBDII Certified". Additionally,

Government regulations mandate that all OBDII compliant vehicles must

have a "common" sixteen-pin Data Link Connector (DLC).

For your vehicle to be OBD II compliant it must have a 16-pin DLC

(Data Link Connector) under the dash and the Vehicle Emission Control

Information Label must state that the vehicle is OBD II compliant.

OBDII 16 pin, BMW series 1-8, I/X/Z, Mini after 2000, all 150 systems,

including Engine, A/T, ABS, ACC, ARS, SRS, EML, A/C, Baterry, BFS,

BZM, CA,CAS, CEM, etc.

Press [UP] or [DOWN] to select ON/OFF and press [ENTER] to confirm.

When this function is ON, and the icon record Datastream and record

Freeze Frames.

USER’S MANUAL

OBDII Auto Scanner

14

Press [ESC] to back to the Main Menu of Diagnostic, the screen will

display as following.

con.

Mo nitor Status

MIL status OFF

DTCs in this ECU 5

Readiness supported 6

Readiness complete 0

Readiness not supported 4

Datastream supported 20

Ignition Spark

Protocol type VPW

4.2 OBDII Diagnose

Select [OBDII Diagnose] in Main Menu and press [ENTER], the screen will

display Monitor Status interface as following.

CAUTION: Don't connect or disconnect any test equipment with ignition on

engine running.

con.

Main Menu

OBDII DIAGNOSE

BMW

DTC LOOKUP

REVIEW HISTORY

TOOL SETUP

HELP

USER’S MANUAL

OBDII Auto Scanner

15

According to the above figure to select different item by pressing [UP] or

[DOWN] and press [ENTER] to confirm.

con.

Read Codes

Current DTCs ($03)

Pending DTCs($07)

Permanent DTCs($0A)

4.2.1 Read Codes

Select [Read Codes] and press [ENTER] in Diagnostic Menu. If there are

some codes, the screen will display the codes as shown below:

con.

Current DTC

P0143 1/3

O2 Sensor Circuit Low Voltage Bank 1 Sensor

3

con.

Di agnostic Menu

Read codes

Erase codes

I/M readiness

Data stream

Freeze frame

O2 sensor test

On-Board monitoring

EVAP system test

USER’S MANUAL

OBDII Auto Scanner

16

Press [ENTER] to erase DTC shown below:

According to the above figure to press [ENTER] and the screen will display

the interface as shown on the next page:

con.

Erase DTC

Clear / Reset Emission-Related

Diagnostic Information, Are you sure?

4.2.2 Erase Codes

Select [Erase Codes], the screen will display the interface as shown

below:

1/3 indicates there are 3 codes total and now P0143 is the first code to

display.

The screen will also show the content of the code below the number of

code.

You can use [ESC]key to view the next code.

After viewing all the codes, you can press [ESC] to return to the Diagnostic

Menu.

con.

Erase DTC

Please turn ignition ON with Engine

Off, press ENTER key to continue!

USER’S MANUAL

OBDII Auto Scanner

17

I/M Readiness

Since DTCs Were Cleared

This Drive Cycle

4.2.3 I/M Readiness

I/M refers to Inspection and Maintenance that is legislated by the

Government to meet federal clean-air standards. I/M Readiness

indicates if or not the various emissions-related systems on the vehicle

operating properly and ready for I/M testing.

The purpose of the I/M Readiness Monitor Status is to indicate which of

the vehicle described in Chapter 2.5), and which ones have not yet run

and completed testing and diagnosis of their designated sections of the

vehicle system.

The I/M Readiness Monitor Status function also can be used (after

repair of a fault has been performed) to confirm that the repair has been

performed correctly, and/or to check for Monitor Run Status.

Select [I/M Readiness] and press [ENTER], the screen will display the

interface as shown below:

Notes:

Before performing this function, make sure to retrieve and record the

trouble codes.

After clearing, you should retrieve trouble codes once more or turn

ignition on and retrieve codes again. If there are still some trouble codes in

the system, please troubleshoot the code using a factory diagnosis guide,

then clear the code and recheck.

Erase DTC

Emission-Related Diagnostic

Information has been Cleared!

USER’S MANUAL

OBDII Auto Scanner

18

Datas tream

View All Items

Select Items

View Graphic Items

4.2.4 Data Stream

Press [UP] or [DOWN] button to select Data Stream in Main Menu

interface and then press [ENTER] button to confirm, the screen will display

the interface as shown below:

You can use [LEFT ] [RIGHT ] button to view other data of vehicle. Press

[ENTER] to return to Diagnostic Menu.

N/A means not available on this vehicle, INC means incomplete or not

ready, OK means Completed or Monitor OK.

con.

I/ M Readiness

Misfire monitor OK

Fuel system monitor N/A

Comprehensive component monitor OK

Catalyst monitor OK

Heated catalyst monitor N/A

Evaporative system monitor OK

Secondary air system monitor N/A

Oxygen sensor monitor OK

Oxygen sensor heater monitor N/A

EGR and/or VVT sensor monitor OK

1/2

You can use [UP] or [DOWN] button to select and press [ENTER], the

screen will display the interface as shown below:

USER’S MANUAL

OBDII Auto Scanner

19

con.

Al l Datastream

Fuel system 1 status N/A

Fuel system 2 status N/A

Calculated LOAD value 2.0%

Engine coolant temperature -35 C

Short term fuel trim - bank 4 -36.1%

con.

Sel ect Datastream

[ ] Fuel system 1 status

[ ] Fuel system 2 status

[ ] Calculated LOAD value

[ ] Engine coolant temperature

[ ] Short term fuel trim - bank 4

1/8

1/1

Select [View All Items] and press [ENTER] button, the screen will display

the interface as shown below:

You can use [LEFT] [RIGHT] button to view other data streams. Press

[ENTER] to return to Diagnostic Menu.

Select [select Items] in Data stream menu and press [ENTER], the screen

will display the interface as shown below:

You can use [UP] [DOWN] button to select data stream items, and press

[LEFT ] [RIGHT] button to turn page, the screen will display the interface

as shown on the next page:

Table of contents

Other Leagend Test Equipment manuals