4

Preface

745-573-B0-001 REV. A

Contents

Important Safety Instructions...................................................................................................................... 6

General Safety Precautions ....................................................................................................................... 7

Battery Safety Notes .................................................................................................................................. 9

Battery Maintenance Guidelines .............................................................................................................. 10

Recycling and Disposal Instructions..........................................................................................................11

Electrical Safety.........................................................................................................................................11

Mechanical Safety.................................................................................................................................... 12

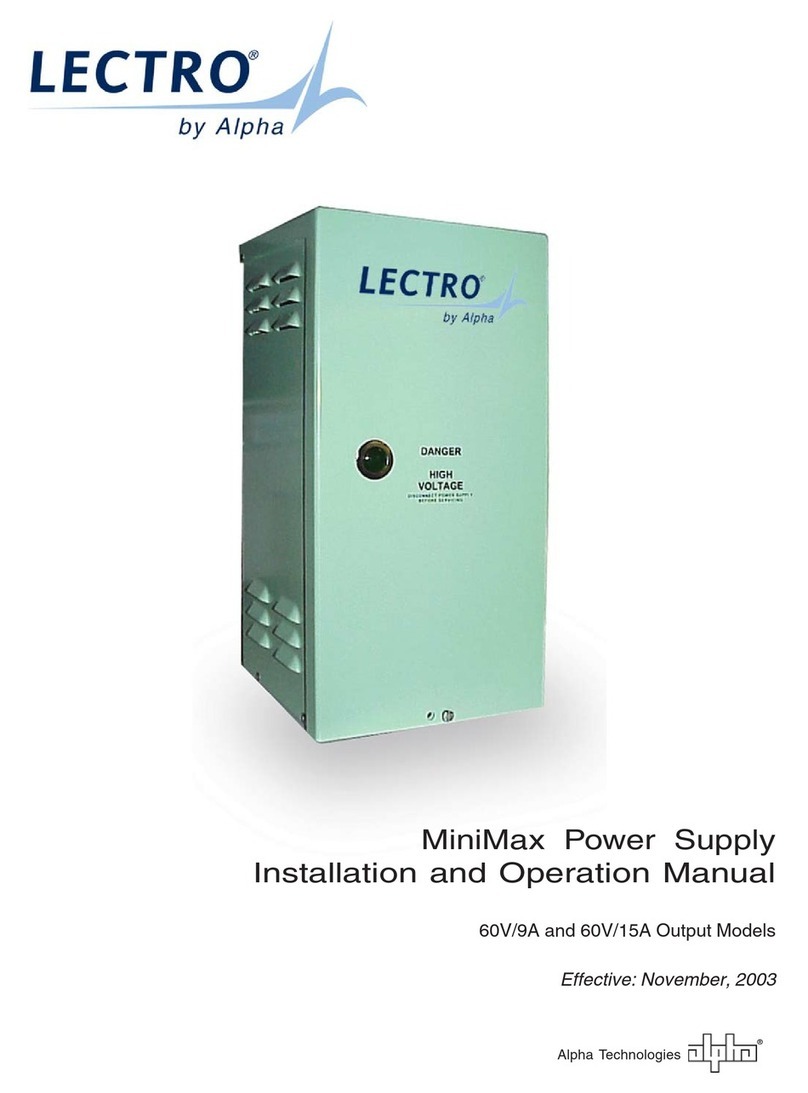

1.0 Overview

1.1 Introduction..................................................................................................................................... 13

1.2 Cabinet Nomenclature.................................................................................................................... 14

2.0 Cabinet Installation

2.1 Pole Mounting................................................................................................................................. 16

2.2 Ground Mounting............................................................................................................................ 18

2.3 Enclosure Grounding...................................................................................................................... 20

2.4 Electrical Connections .................................................................................................................... 21

3.0 Power Supply Installation

3.1 CPR™ Module Installation and Connection ................................................................................... 22

3.2 Battery Installation and Connection ................................................................................................ 25

3.2.1 48V Battery Installation Procedure ........................................................................................26

3.2.2 36V Battery Installation Procedure ........................................................................................27

3.2.3 Connecting an Additional 48V Battery String ......................................................................... 28

3.2.4 Connecting an Additional 36V Battery String ......................................................................... 28

3.2.5 Removing Batteries ............................................................................................................... 30

3.3 Operation........................................................................................................................................ 33

3.4 Maintenance ................................................................................................................................... 35

3.4.1 Routine Maintenance Checks................................................................................................35

3.4.2 CPR™ Power Supply Maintenance Log Sheet ..................................................................... 36

3.4.3 Battery Storage ...................................................................................................................... 37

3.4.4 Proper Usage ........................................................................................................................ 37

3.4.5 Periodic Maintenance ............................................................................................................ 37

4.0 Troubleshooting

4.1 Troubleshooting Guide Part 1......................................................................................................... 38

4.2 Troubleshooting Guide Part 2......................................................................................................... 39

5.0 Status Monitoring

5.1 Installation ...................................................................................................................................... 40

5.2 Operation........................................................................................................................................ 41

5.3 Maintenance ................................................................................................................................... 42

6.0 Specifications

6.1 Electrical, Mechanical Specifications .............................................................................................. 43